2. Machining Parameters

2.5 Tool Measurement Parameters

II - 16

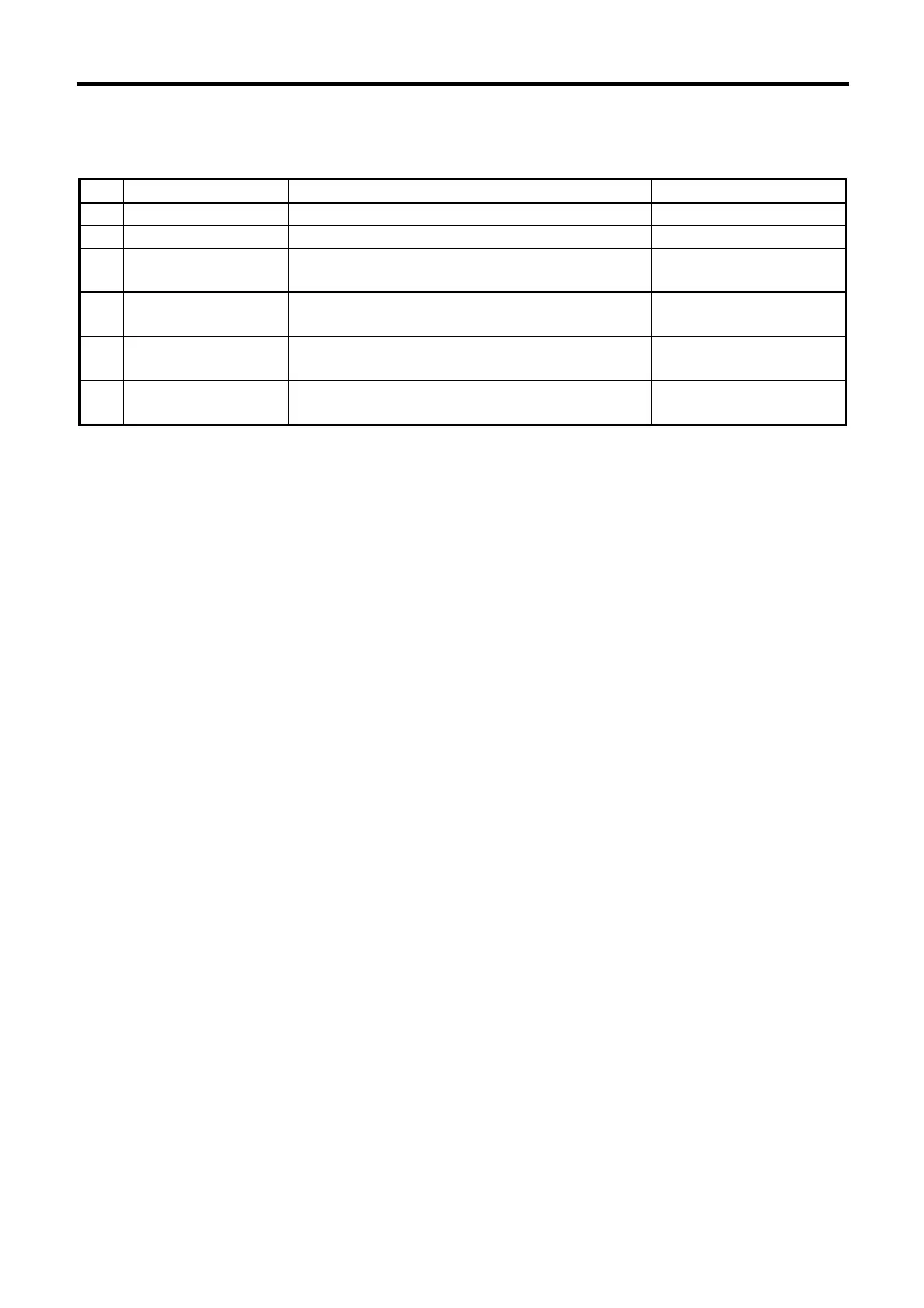

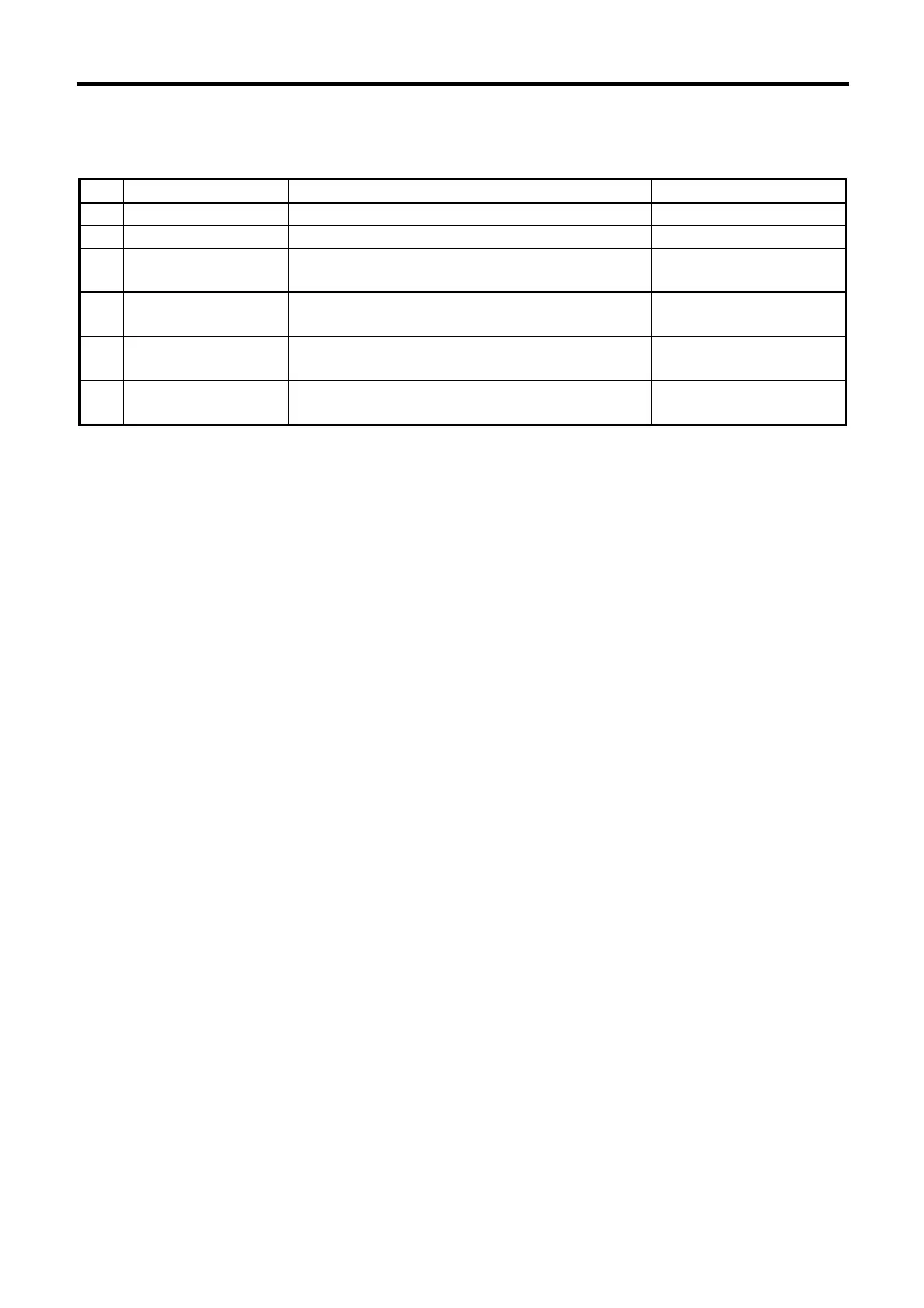

2.5 Tool Measurement Parameters

Set up the parameter of the tool (touch tool sensor), etc, used for measurement.

# Item Contents Setup range (unit)

8701 Tool length Set the length to the end of the touch tool. ±99999.999 (mm)

8702 Tool Dia Set the spherical diameter of the touch tool end. ±99999.999 (mm)

8703 OFFSET X Set the spindle center deviation amount from the

touch tool center in the X axis direction.

±99999.999 (mm)

8704 Y Set the spindle center deviation amount from the

touch tool center in the Y axis direction.

±99999.999 (mm)

8705 RETURN Set the return distance to contact the touch tool

against the workpiece again.

±99999.999 (mm)

8706 FEED Set the feedrate when contacting the touch tool

against the workpiece again.

1 to 60000 (mm/min)

Loading...

Loading...