APPENDIX

App. - 13

App. 4.6 Maintenance and service

WARNING

To avoid an electric shock, only qualified personnel should attempt inspections.

For repair and parts replacement, contact your local sales office.

CAUTION

Do not perform insulation resistance test on the servo amplifier. Otherwise, it may

cause a malfunction.

Do not disassemble and/or repair the equipment on customer side.

App. 4.6.1 Inspection items

It is recommended that the following points periodically be checked.

(1) Check for loose terminal block screws. Retighten any loose screws.

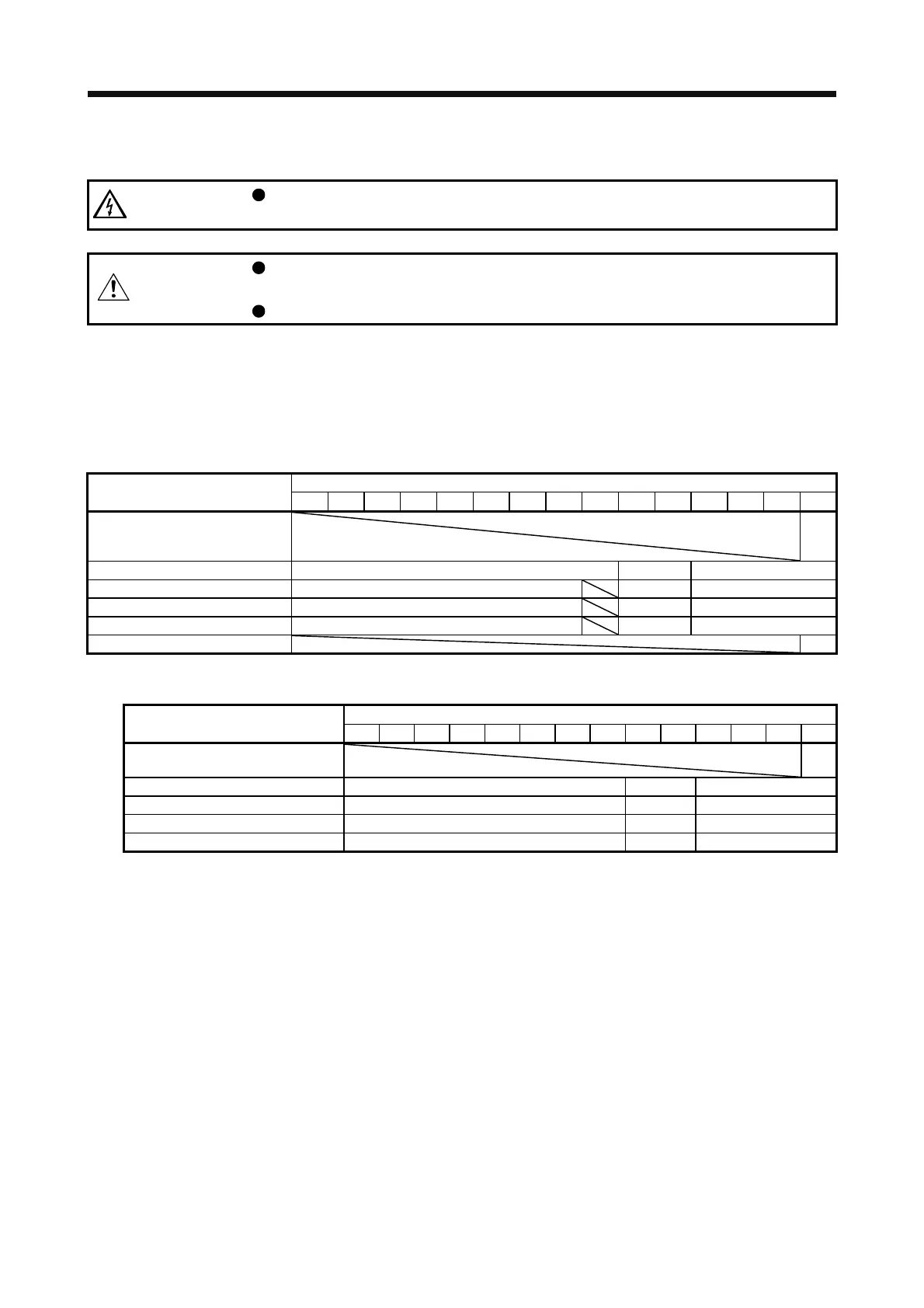

(a) 200 V class

Tightening torque [N•m]

Servo amplifier

L1 L2 L3 N- P3 P4 P+ C D L11 L21 U V W PE

MR-J4-10_/MR-J4-20_/MR-J4-

40_/MR-J4-60_/MR-J4-70_/MR-J4-

100_/MR-J4-200_/MR-J4-350_

1.2

MR-J4-500_ 1.2 0.8 1.2

MR-J4-700_ 1.2 0.8 1.2

MR-J4-11K_•MR-J4-15K_ 3.0 1.2 3.0

MR-J4-22K_ 6.0 1.2 6.0

MR-J4W_-_B 1.2

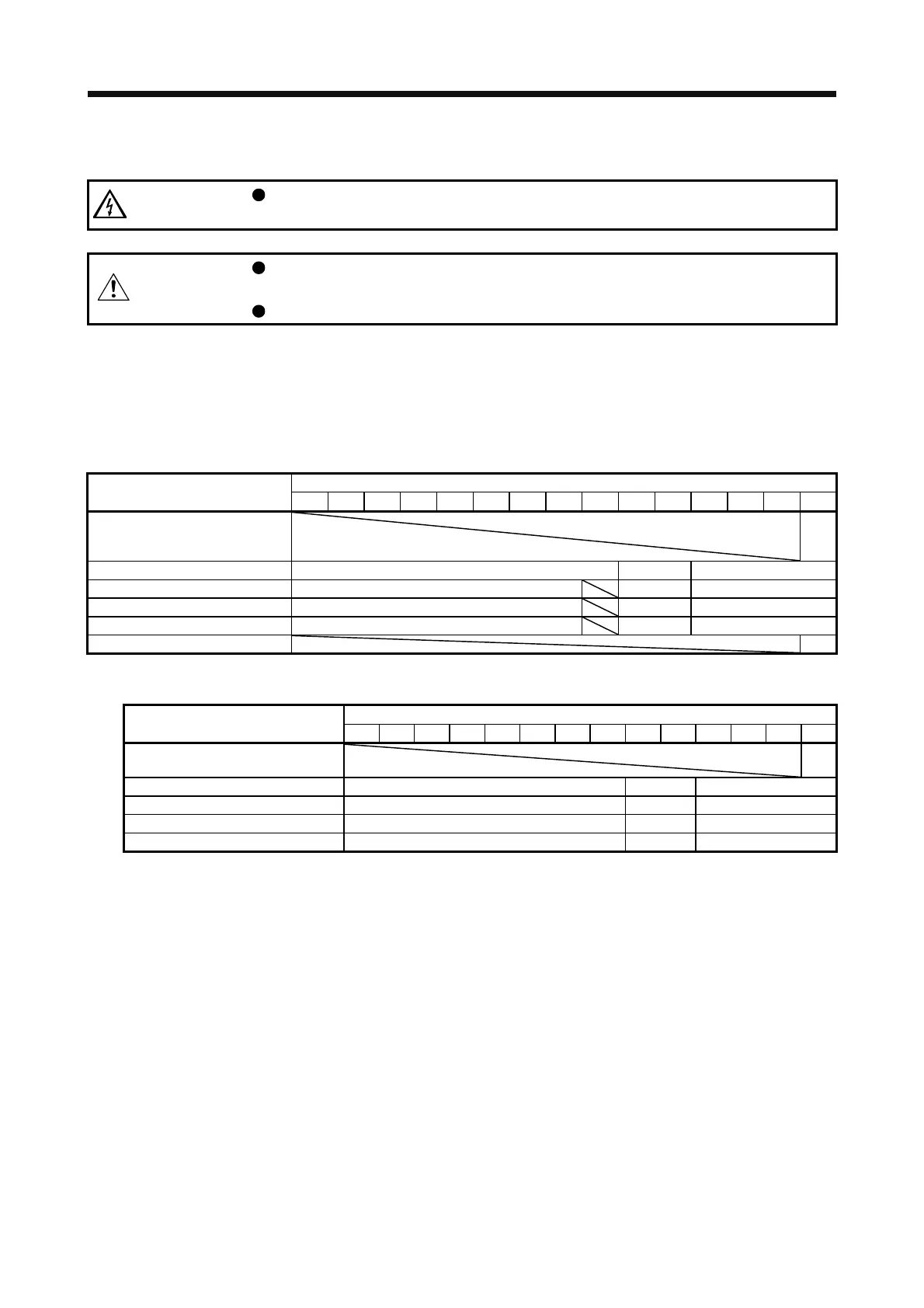

(b) 400 V class

Tightening torque [N•m]

Servo amplifier

L1 L2 L3 N- P3 P4 P+ C L11 L21 U V W PE

MR-J4-60_4/MR-J4-100_4/

MR-J4-200_4/MR-J4-350_4

1.2

MR-J4-500_4 1.2 0.8 1.2

MR-J4-700_4 1.2 0.8 1.2

MR-J4-11K_4/MR-J4-15K_4 3.0 1.2 3.0

MR-J4-22K_4 6.0 1.2 6.0

(2) Check servo motor bearings, brake section, etc. for unusual noise.

(3) Check the cables and the like for scratches or cracks. Perform periodic inspection according to

operating conditions.

(4) Check that the connectors are securely connected to the servo motor.

(5) Check that the wires are not coming out from the connector.

(6) Check for dust accumulation on the servo amplifier.

(7) Check for unusual noise generated from the servo amplifier.

(8) Check the servo motor shaft and coupling for connection.

Loading...

Loading...