114 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

ENGLISH

STARTER ELECTRICAL SYSTEM

ELECTRICAL SYSTEM

27 STARTER

27.1 Inspection before disassembly

(inspection of assembly)

If an abnormality is found, disassemble and repair.

1. Pinion gap

1) Connect the positive (+) cable of the battery to

terminal S of the starter and the negative (-)

cable to the starter body to extend the pinion.

2) Lightly press the tip of the extended pinion

shaft with a finger, and measure the distance

of the shaft movement.

3) If the measured value is not within a range of

0.1 to 2.5 mm [0.0039 to 0.0984 in.], increase

or decrease the number of packings at the

magnetic switch section for adjustment. An

increase of packings results in a decrease of

the pinion gap.

2. No-load test

1) As shown in the diagram, connect an

ammeter, voltmeter, revolution indicator and

battery.

2) Turning on the switch should extend the pinion

and operate the starter at the specified speed

or faster.

If the current or rotating speed does not

conform to the standard value, disassemble

the starter for inspection and repair.

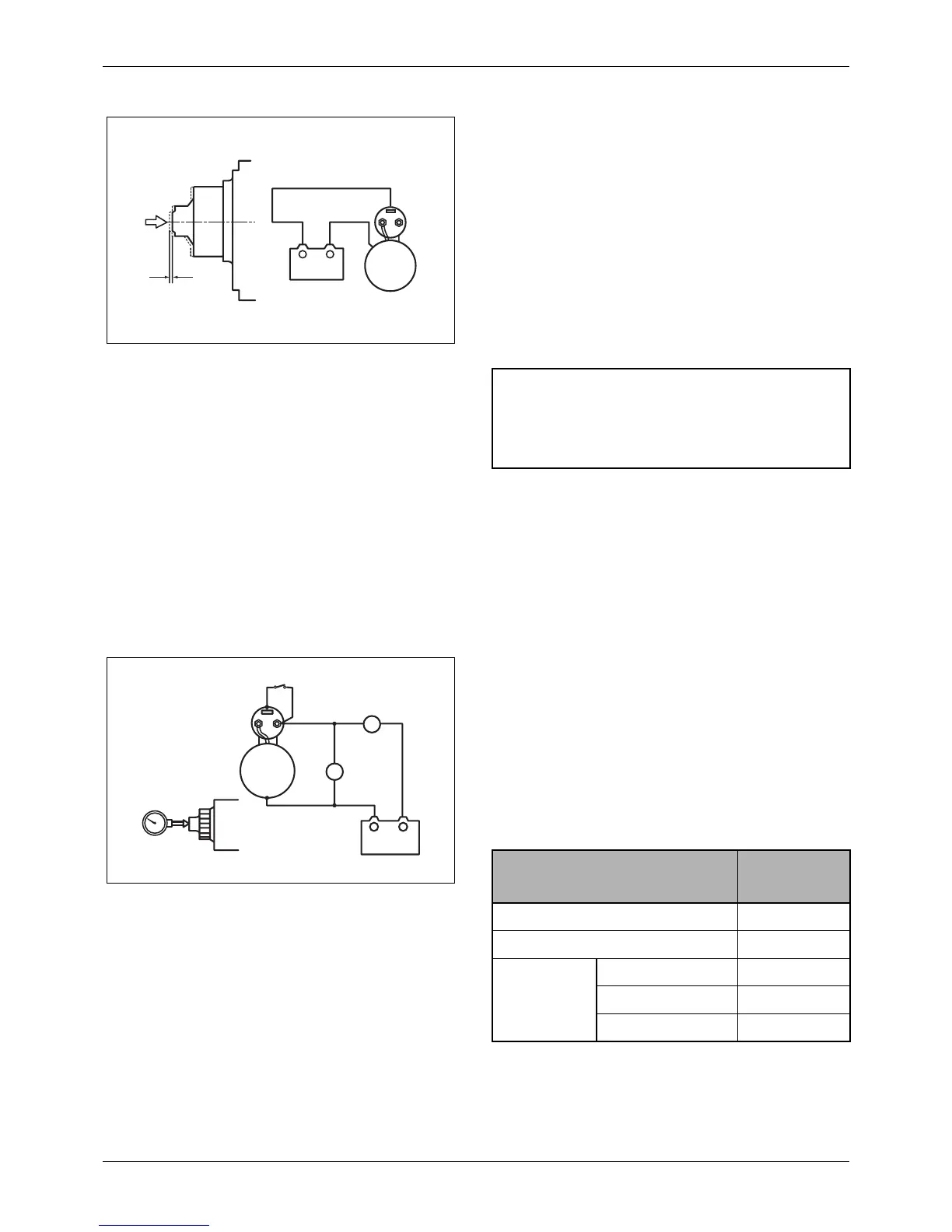

Figure 181 Inspection of pinion gap

+ -

12V

S

Lightly press

the tip

0.1 to 2.5 mm

[0.0039 to

0.0984 in.]

24V (option)

Starter

Battery

CAUTION

Do not supply electricity for more than 10 continuous

seconds.

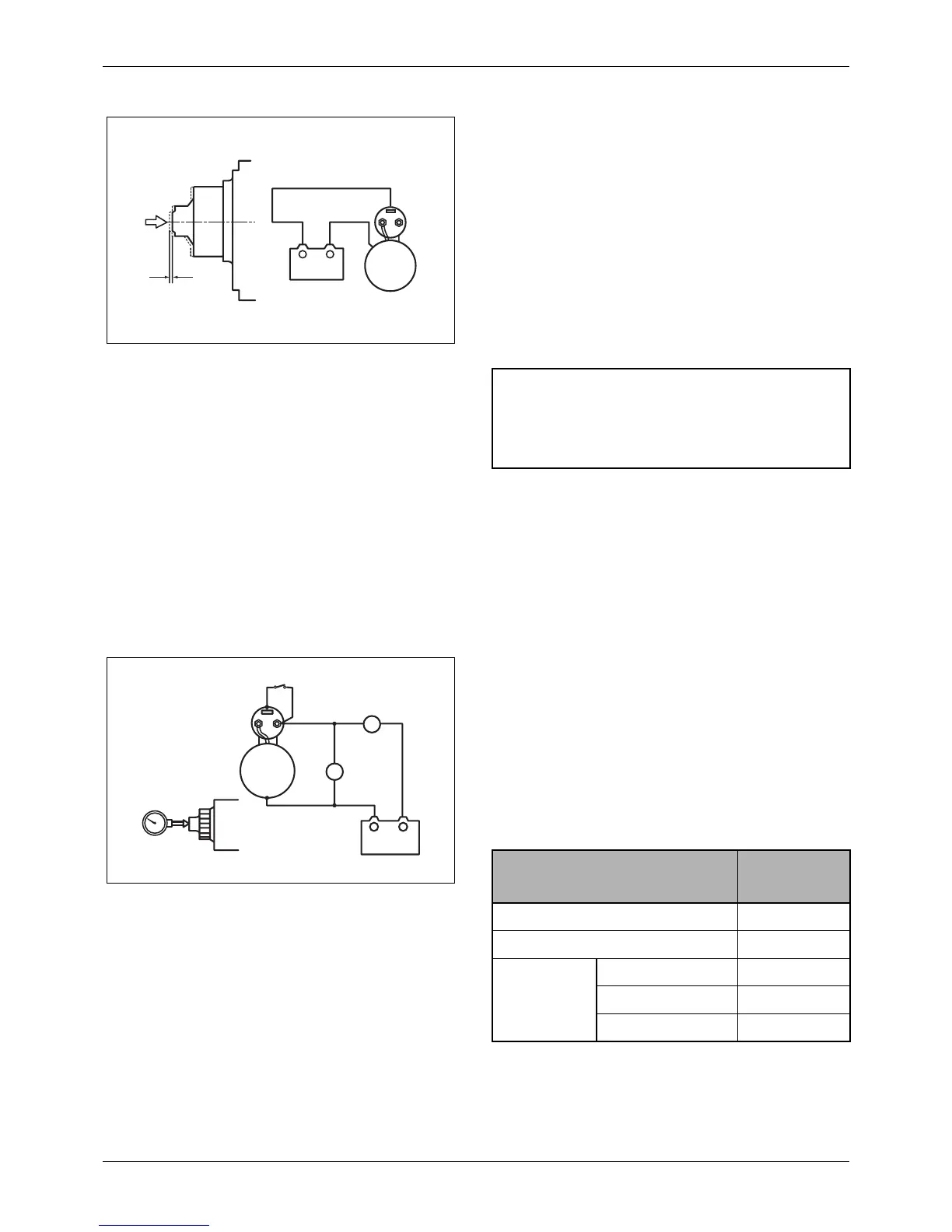

Figure 182 No-load test

-

+

12V

V

A

Switch

Revolution

indicator

24V (option)

Starter

Battery

Ammeter

Item

Standard

value

Starter model M008T70371

Nominal output V-kW 12-2.0

No-load

characteristics

Terminal voltage V 11

Current A 130 or lower

Rotation speed rpm 3600 or higher

Loading...

Loading...