41 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

FLYWHEEL

ENGLISH

ENGINE MAIN PARTS

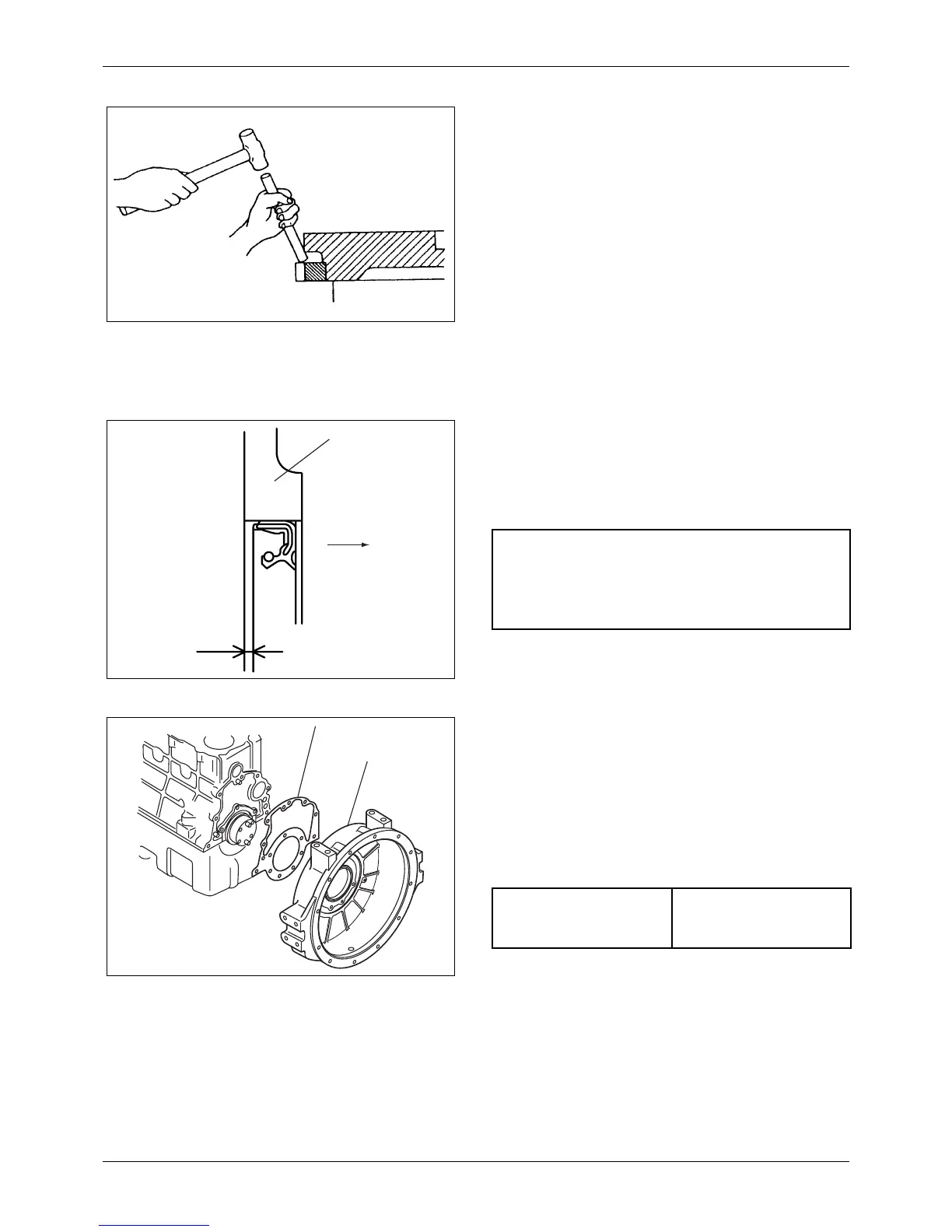

2. Replacing ring gear

(Removal)

1) Heat the ring gear evenly with an acetylene

torch.

2) Tap the ring gear all the way around with a bar

and a hammer to remove it from the flywheel.

(Installation)

Heat a replacement ring gear up to 150°C [302°F]

with a piston heater and install it to the flywheel

with the unchamfered side of the gear teeth fore-

most.

8.3 Reassembly

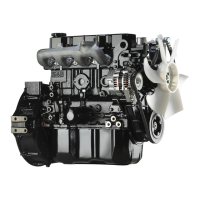

1. Installing oil seal

Apply a small amount of grease to new oil seal and

drive the oil seal to flywheel housing by using

installer.

Be sure oil seal faces to the correct direction.

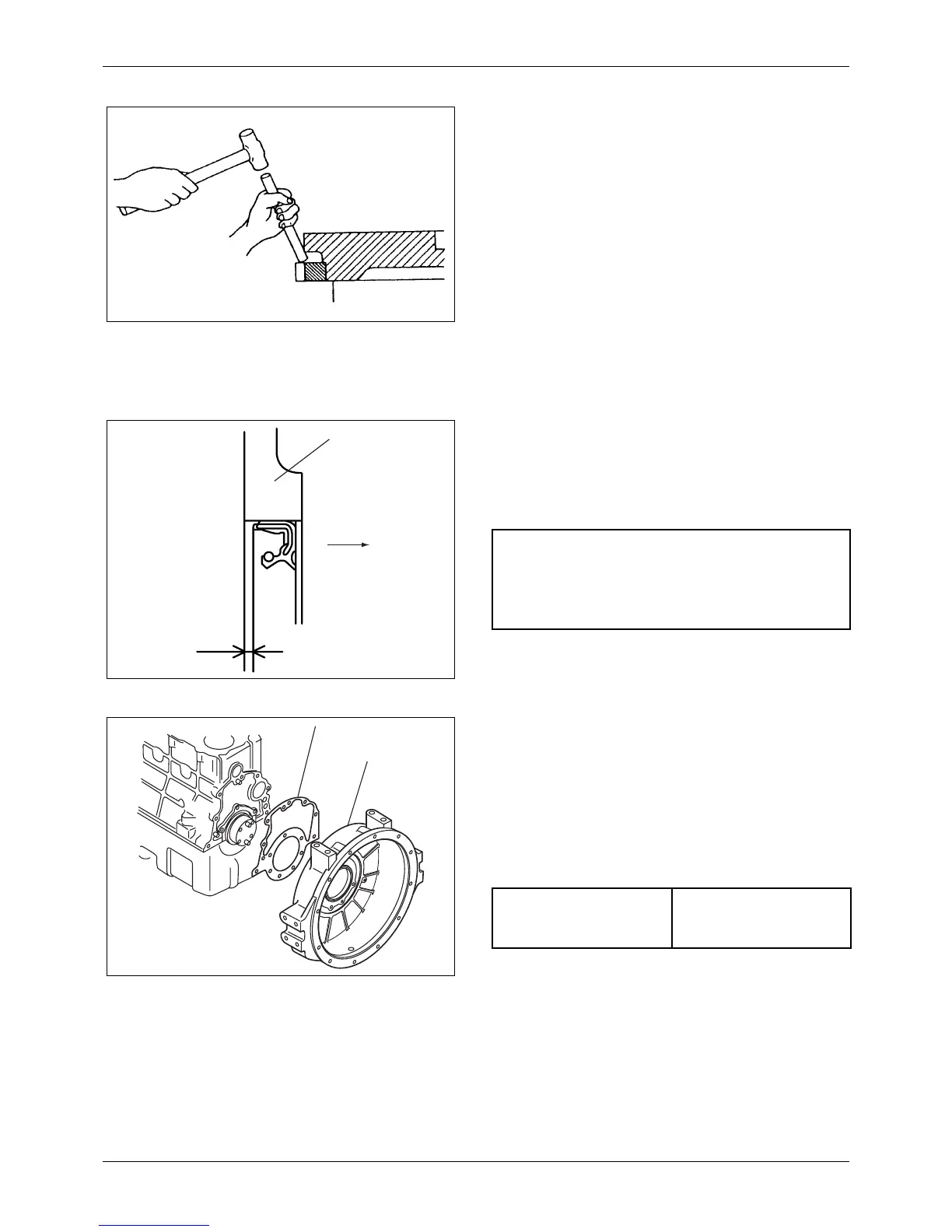

2. Installing flywheel housing

1) Apply THREEBOND 1104 on the mounting

surfaces of both crankcase and flywheel

housing.

2) Install the gasket and flywheel housing on the

crankcase by aligning the holes on the

flywheel with the dowel pins on the crankcase.

3) Tighten the flywheel mounting bolts to the

specified torque.

Figure 53 Removing ring gear

Figure 54 Installing oil seal

Flywheel housing

Flywheel side

2 to 3 mm

[0.08 to

0.12 in.]

NOTE

Replace, if oil seal sleave running surface of

crankshaft is badly worn.

Figure 55 Installing flywheel housing

Gasket

Flywheel

housing

Tightening torque

60 ± 6 N·m

(6.1 ± 0.6 kgf·m)

[44 ± 4 lbf·ft]

Loading...

Loading...