65 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

PISTONS, CONNECTING RODS,

CRANKSHAFT AND CRANKCASE

ENGLISH

ENGINE MAIN PARTS

10.2.1 Pistons, piston rings and piston

pins

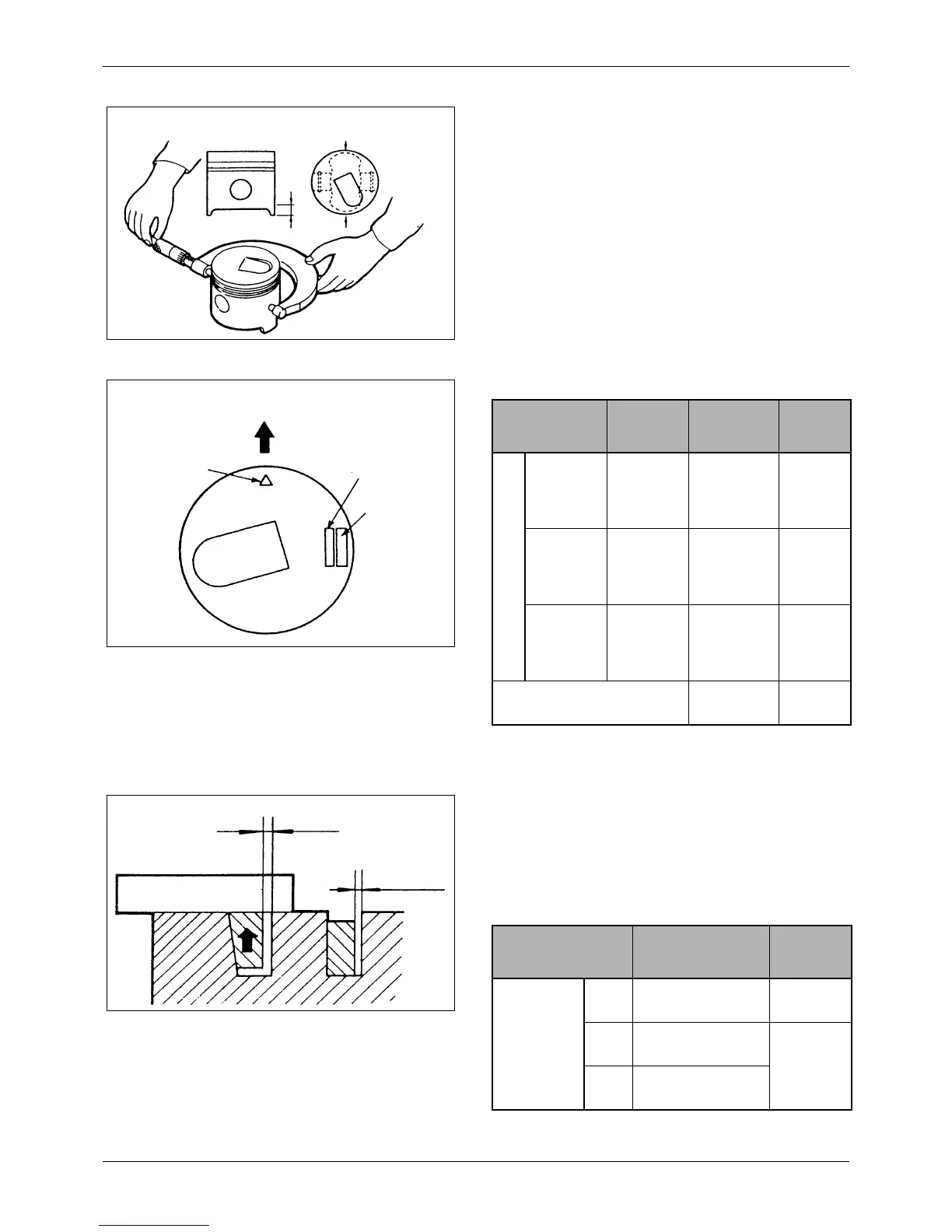

1. Measuring piston diameter

1) Using a micrometer, measure the diameter of

each piston perpendicular to the piston pin (at

the position shown). If the diameter exceeds

the service limit, replace the piston. If any

pistons have to be replaced, select new

pistons so the weight difference in an engine

is within assembly standards.

Unit: mm [in.]

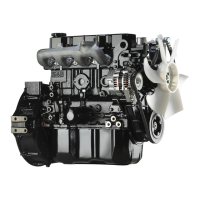

2) The weight of the piston is stamped on the top

of the piston.

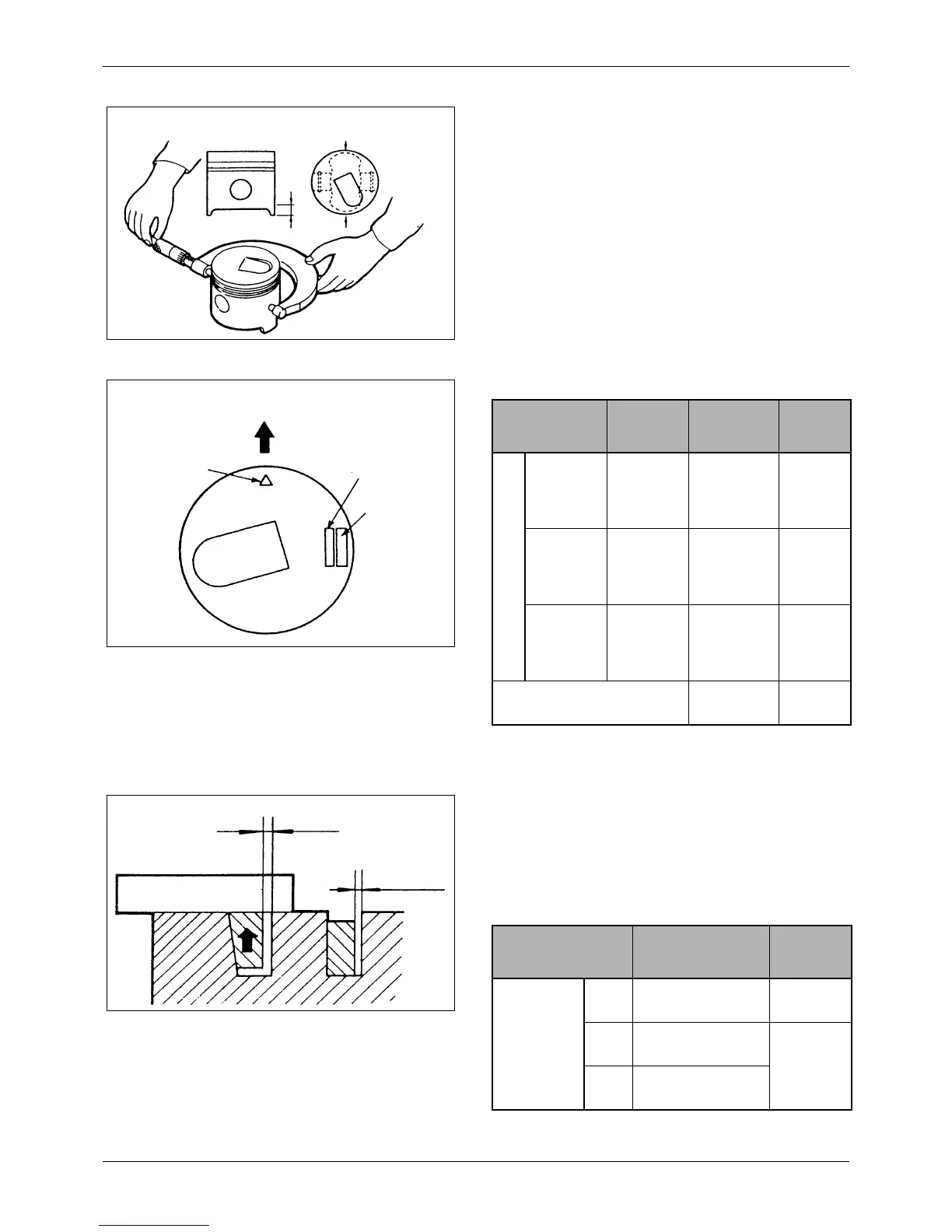

2. Checking piston and piston ring

1) Check the clearance between the groove and

the piston ring with a feeler gage, as shown in

the illustration. If the clearance exceeds the

service limit, replace the piston ring.

Unit: mm [in.]

Figure 108 Measuring piston diameter

Direction transverse

to piston pin

14 mm

[0.6 in.]

Figure 109 Identification on top of piston

Size

identification

Weight

identification

Front of engine

“Front” mark

Item

Nominal

Value

Assembly

Standard

Service

Limit

Piston diameter

Standard

87.970

[3.4634]

87.955 to

87.985

[3.4628 to

3.4640]

87.770

[3.4555]

0.25

[0.0098]

oversize

88.220

[3.4732]

88.205 to

88.235

[3.4726 to

3.4738]

88.020

[3.4654]

0.50

[0.0197]

oversize

88.470

[3.4831]

88.455 to

88.485

[3.4825 to

3.4837

88.270

[3.4752]

Weight difference in one

engine

5 g [0.2 oz]

or less

__

Figure 110 Checking between groove and piston ring

No. 1 ring

No. 2 ring

Item

Assembly

Standard

Service

Limit

Clearance

between

groove and

piston ring

No. 1

ring

0.060 to 0.100

[0.0024 to 0.0039]

0.200

[0.0079]

No. 2

ring

0.045 to 0.080

[0.0018 to 0.0032]

0.150

[0.0059]

Oil

ring

0.025 to 0.065

[0.0010 to 0.0026]

Loading...

Loading...