75 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

PISTONS, CONNECTING RODS,

CRANKSHAFT AND CRANKCASE

ENGLISH

ENGINE MAIN PARTS

d Bore the cylinders to the calculated

dimension.

e Hone the cylinders to the final dimension

(piston outside diameter + cylinder clearance).

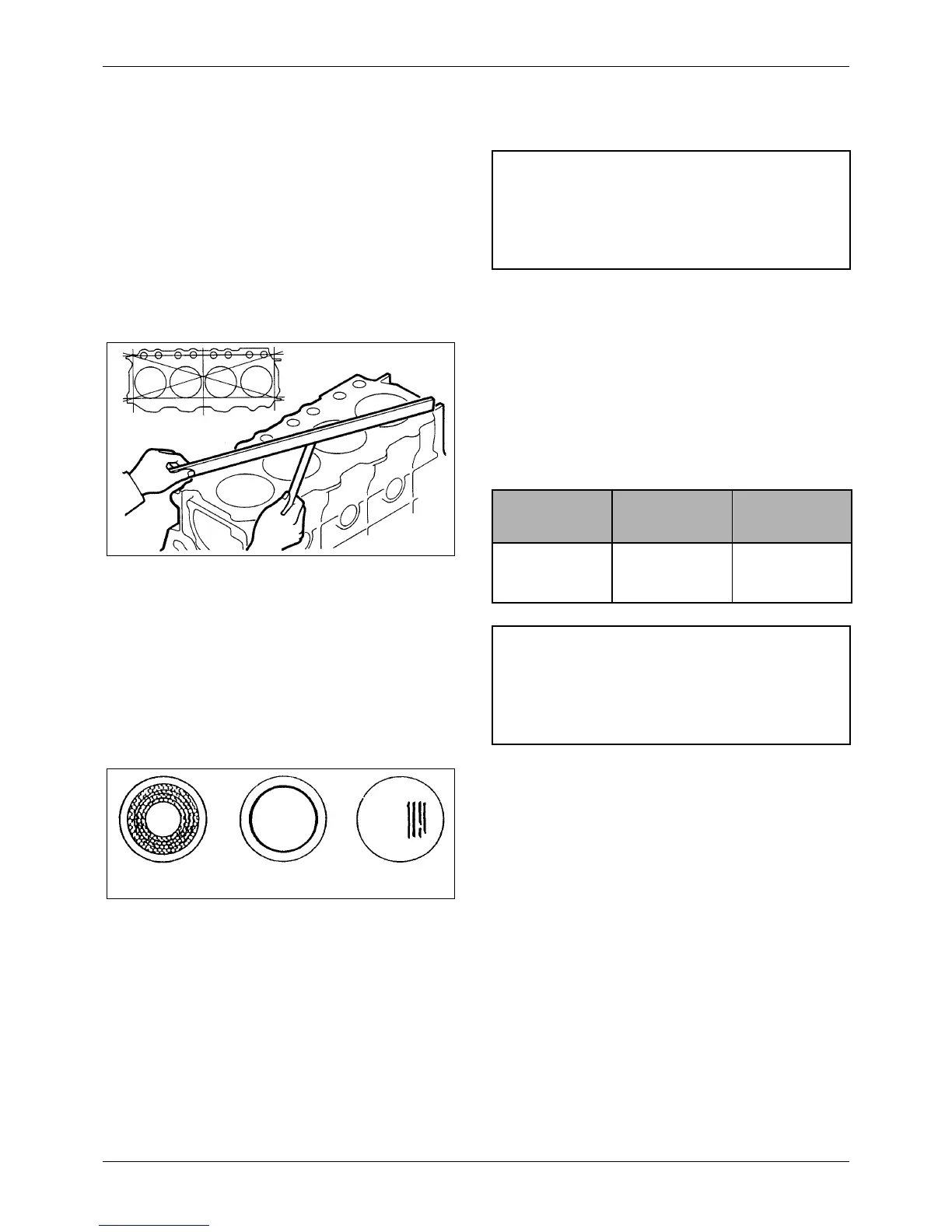

2. Checking crankcase top face

Check the top face for warpage, using an accurate

straight edge and a feeler gage, in three positions

lengthwise, two crosswise and two widthwise, as

shown in the illustration. If warpage exceeds the

repair limit, grind the crankcase.

Unit: mm [in.]

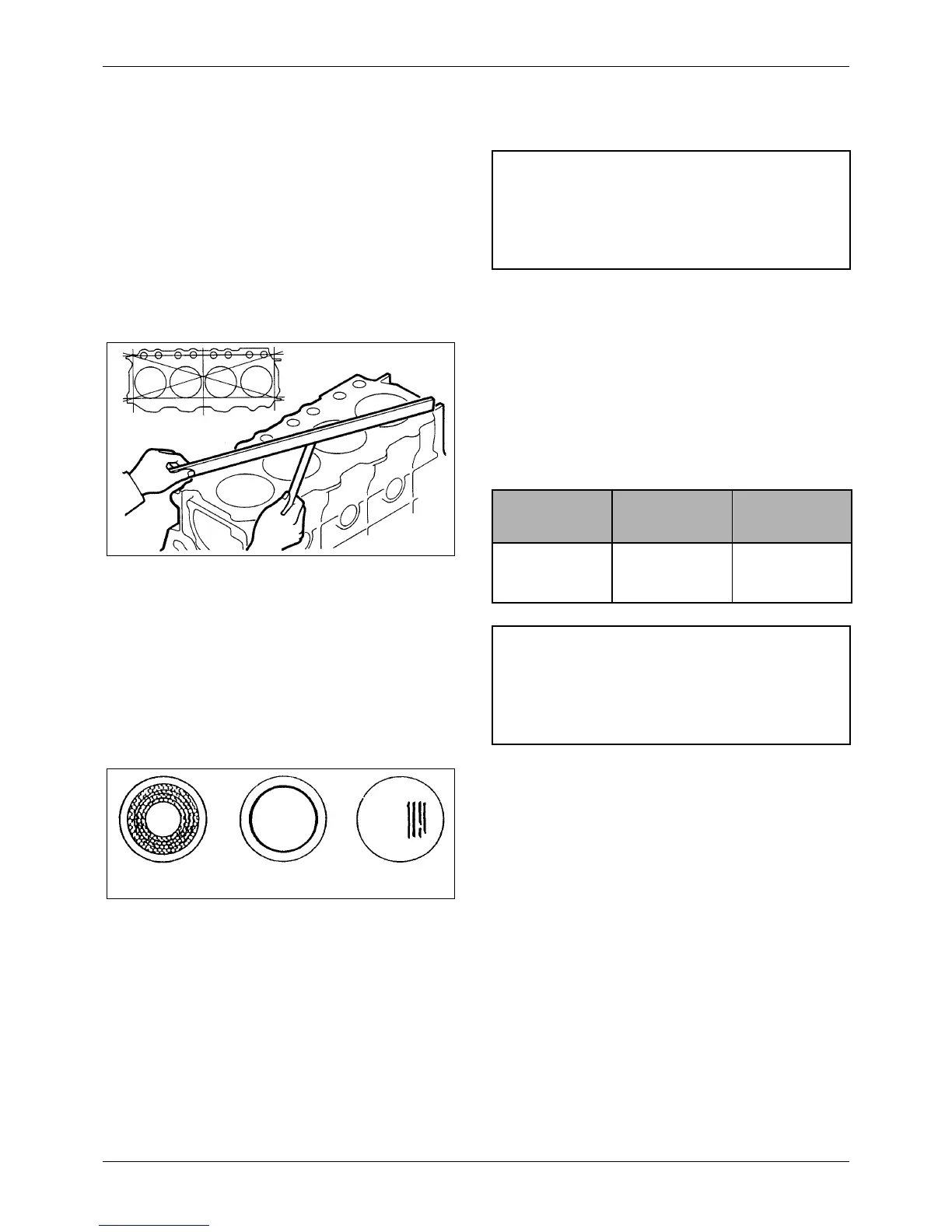

10.2.5 Tappets

1. Checking for wear

Check the cam contact face of each tappet for

wear. Replace badly worn tappets if any.

CAUTION

Before the cylinders in the order of the cylinder

numbers to prevent distortion due to the heat

generated by the boring operation.

Figure 133 Checking crankcase top face

Item

Assembly

Standard

Repair Limit

Warpage of

crankcase top

face

0.05 [0.0020] or

less

0.20

[0.0079]

NOTE

The maximum limit of stock to be removed from the

crankcase and cylinder head for grinding is 0.2 mm

[0.0079 in.] in all.

Figure 134 Cam contact face of tappet

Good Bad Bad

Loading...

Loading...