Printed in Japan

Mitutoyo Corporation 1-20-1 Sakado, Takatsu-ku, Kawasaki City, Kanagawa 213-8533

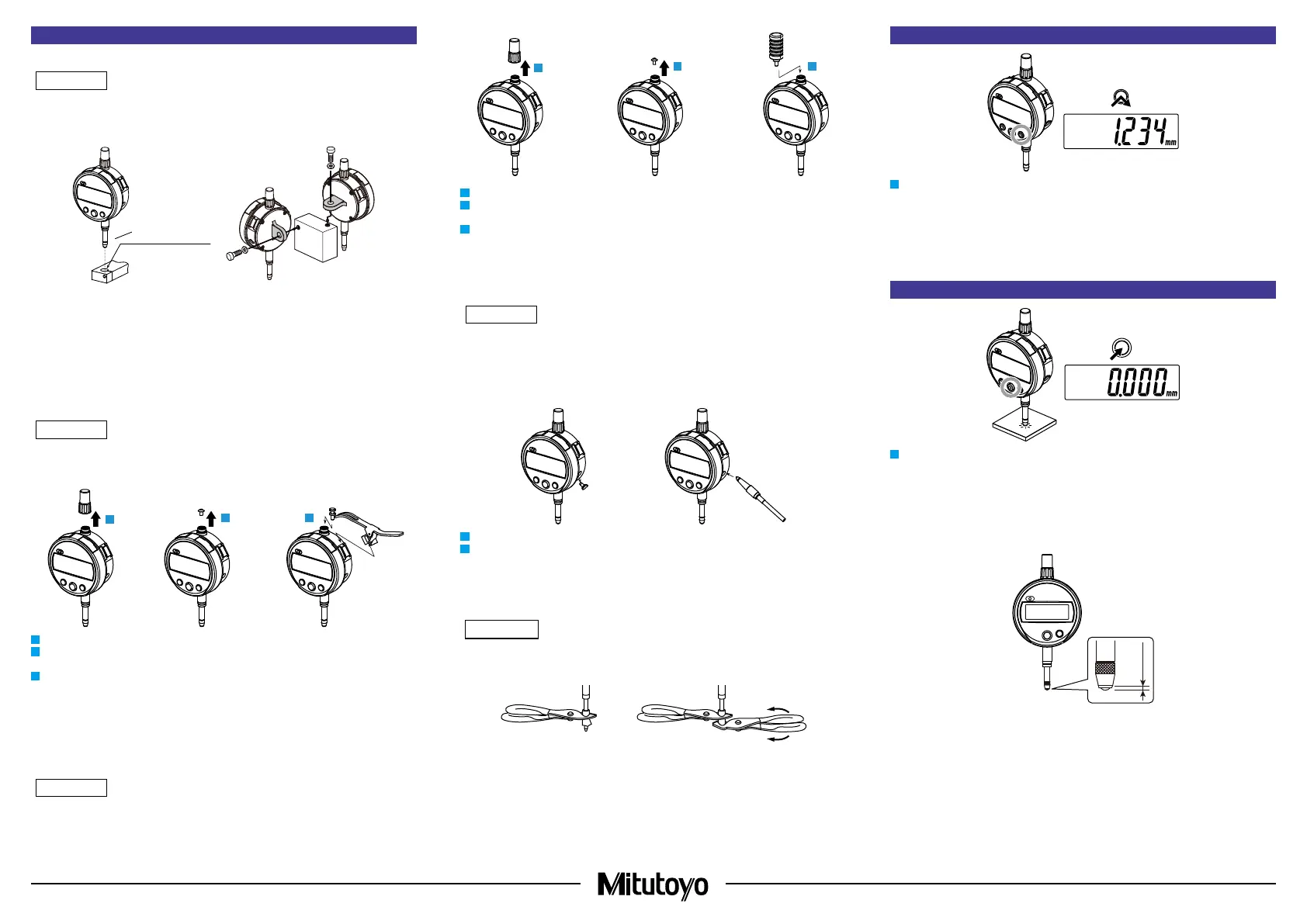

3. Setup

1) Mounting to a stand, jig, etc.

• Whenever possible, avoid xing the stem directly with a set screw, etc.

• The spindle may not be able to move smoothly if the screw is tightened with a tightening torque

of 150 cN•m or more to secure the stem.

ø

8* mm

+0.0 2

+0.0 0 5

*ADG type:

ø

9.52 (3/8 in)

Tips

When mounting the product to a stand or jig, use the stem or lug on the back. If using the stem,

use a slotted holder with a ø8 mm or ø9.52 mm hole with G7 (+0.005 mm to +0.02 mm).

2) Mounting the lifting lever

[Options: Part No. 21EZA198 (mm), part No. 21EZA199 (in)]

•

Using the product while the stop screw is not secured rmly may damage internal components or the workpiece.

• If not mounting a stop screw, always mount the original screw on the spindle top end.

Otherwise internal components or the workpiece may be damaged.

1

2 3

1

Rotate the cap counterclockwise to remove it from the product.

2

Fix the spindle, using pliers padded with a rag, etc., so that it does not turn, and then remove

the screw (M2.5 or No.4-48UNF) at the top end of the spindle.

3

Mount the stop screw supplied with the lifting lever and, with the lever tip caught by the stop

screw, mount the lifting lever on the lifting lever mount (dovetail).

Tips

Store the removed screw and cap to prevent loss.

3) Mounting the lifting knob

[Options: Part No. 21EZA105 (mm), part No. 21EZA150 (in)]

•

Using the product while the lifting knob is not secured rmly may damage internal components or the workpiece.

• If not mounting a lifting knob, always mount the original screw on the spindle top end.

Otherwise internal components or the workpiece may be damaged.

1

2 3

1

Rotate the cap counterclockwise to remove it from the product.

2

Fix the spindle, using pliers padded with a rag, etc., so that it does not turn, and then remove

the screw (M2.5 or No.4-48UNF) at the top end of the spindle.

3

Mount the lifting knob on the top end of the spindle.

Tips

Store the removed screw and cap to prevent loss.

4) Mounting the release (Optional part No. 540774)

• Always mount the rubber cap if a release is not mounted.

• The rubber cap is a screw-in type.

• The product may be damaged if an item other than the release is inserted or if excessive force

is applied.

• Raising or lowering the spindle while the release is not secured rmly may damage the internal

components.

1

Remove the rubber cap from the release mounting hole.

2

Screw the release rmly into the hole.

Tips

Store the removed screw and rubber cap to prevent loss.

5) Contact point replacement

When replacing the contact point, turn the contact point while xing the spindle. Otherwise, the

product may be damaged.

Mount and remove the contact point with a rag and 2 pairs of pliers (one for xing the spindle) as

shown in the gure.

Tips

• Changing the contact point may cause changes in external dimensions and measurement

force, or restrictions on measurement directions.

• Errors due to the contact point (perpendicularity of at contact point, center runout of roller con

-

tact point, etc.) are added to the measurement accuracy.

• Various contact points are available as options. Refer to the Mitutoyo MEASURING INSTRU

-

MENTS CATALOG for details.

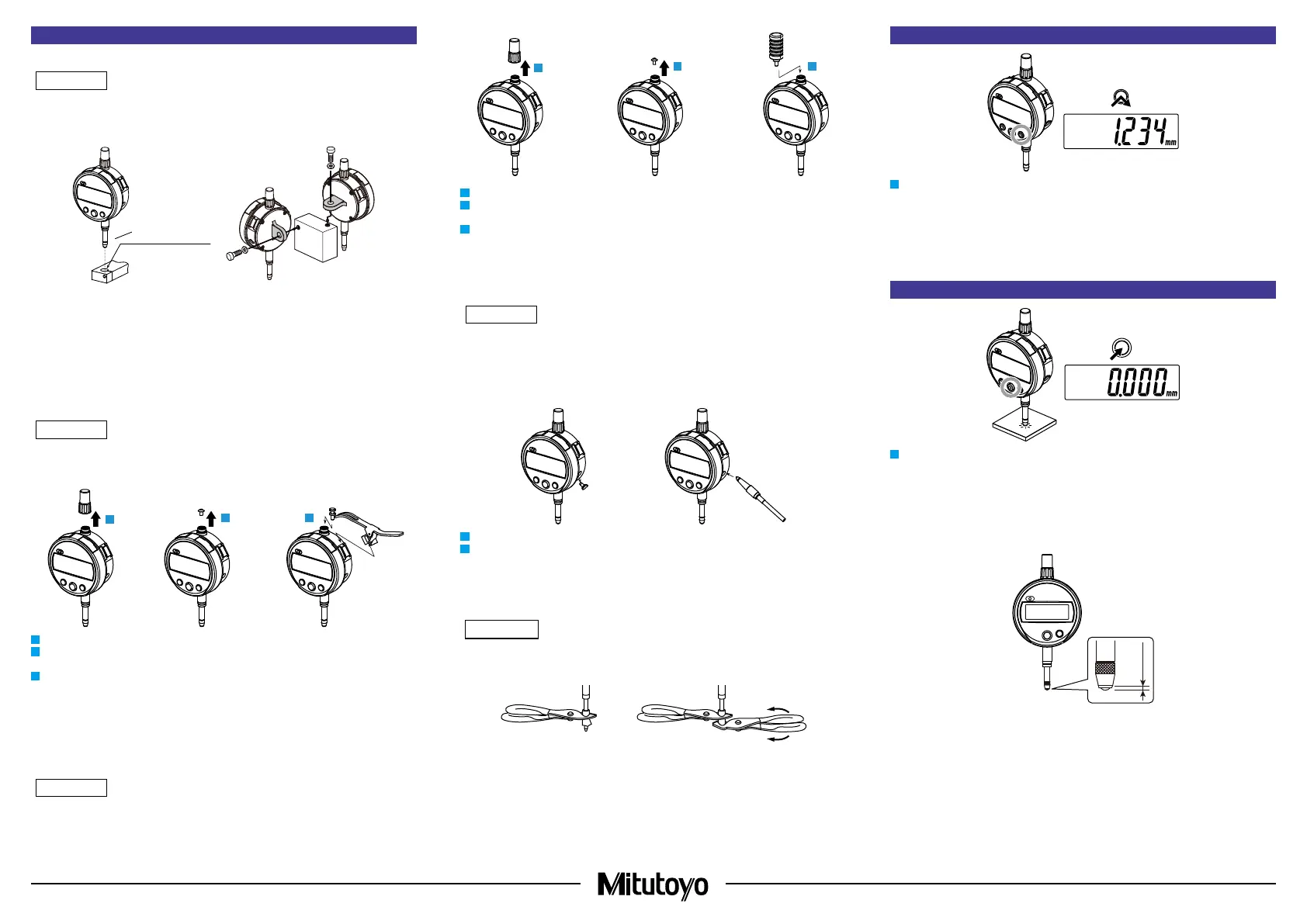

4. Power ON/OFF

ON/OFF

1

Press the [ON/OFF] key to turn the product on and o.

Tips

• If the power does not turn on even when the [ON/OFF] key is pressed, the battery may be

dead. Replace the battery.

• Although the spindle may feel heavy at the bottom dead center when using for the rst time,

this can be resolved by pushing the spindle up once.

•

Even after the power is turned o, the reference point set and counting direction will be retained.

5. ORIGIN Setting (Reference Point Setting)

Master

ORIGIN

1

Move the spindle to the point to be set as the reference point, and then press the [ORIGIN] key

for 1 second or more.

⇨

The indicated value becomes zero and the reference point (ORIGIN) is set.

Tips

• Place the contact point on the workpiece several times to verify that the measured value is stable.

• This product does not guarantee stable repeatability within 0.2 mm from the bottom dead

center (when the spindle is completely extended). When performing reference point setting, be

sure to lift the spindle at least 0.2 mm above the bottom dead center.

0.2 mm

• A rubber damper is attached to this product to soften the spindle impact. Although the indicated

value may not be stable at the bottom dead center due to the elasticity of the damper, this is

not a malfunction.

Stem

Loading...

Loading...