Engineering

03/05 AWB2724-1453GB

18

Lightning protection

External lightning protection

All cables that go outside buildings must be shielded. Metal

conduit is the best solution to this problem. For signal cables, use

overvoltage protection devices, such as Varistors or other similar

devices. Install the protection devices as close as possible to the

cable entry into the building, at the latest there were the cable

enters the switchgear cabinet.

Internal lightning protection

Internal lightning protection covers all those measures taken to

reduce the effects of a lightning strike and the resulting electrical

and magnetic fields on metallic installation and electrical plant.

These measures are:

• equipotential bonding/earthing

• shielding

• using overvoltage protection devices.

Please consult the following manuals for advice on cable routing

and shielding measures:

• AWB27-1287 “EMC Project Engineering for Automation

Systems”.

• TB27-001-GB “Electromagnetic Compatibility (EMC) for

Automation systems”.

• TB02-022-GB “Electromagnetic Compatibility (EMC) for

Machinery and Plant”.

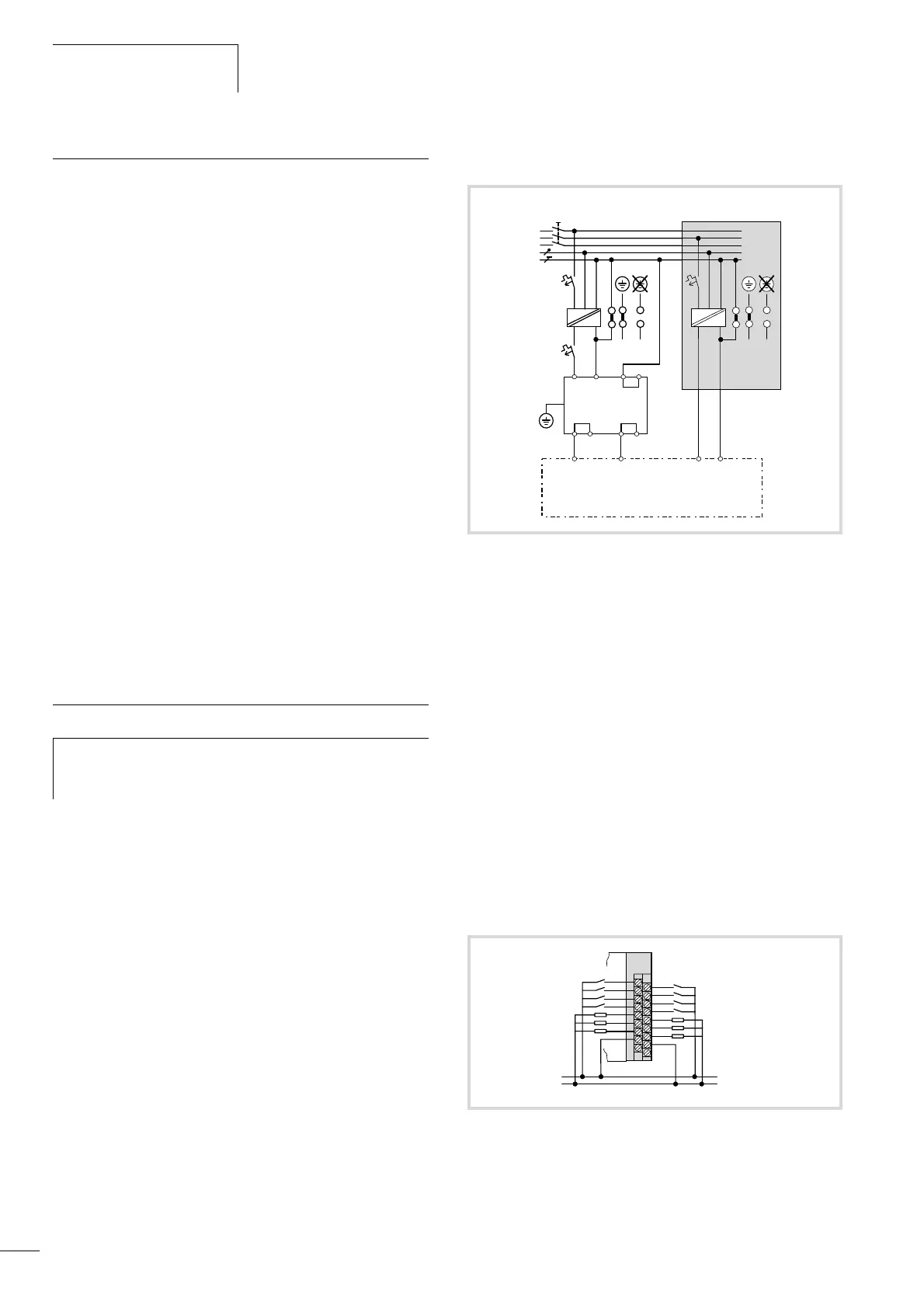

Wiring example

PSU

Power supply of the digital inputs/outputs

The wiring example indicates the wiring of a separate voltage

supply for inputs/outputs.

h

You can find wiring examples for the XI/OC modules in

the manual “Hardware and Engineering, XI/OC signal

Modules” (AWB2725-1452GB).

Figure 18: Wiring example for the supply section

a Main switch

b Protective cut-out

c 24 V DC supply voltage

d Earthed operation

e In floating (i.e. unearthed) operation, an isolation monitor must be

used (IEC 204-1, EN 60204-1, DIN EN 60204-1)

f 24 V DC line filter; ensures that a current of up to 2.2 A (maximum)

is available at a rated voltage of 24 V DC. Ensures that the EMC

stipulations for devices are fulfilled when the filter is used. The filter

is not a component of the CPU and must therefore be ordered

separately:

Type: XT-FIL-1

, Article no.: 285316 (Supplier: Moeller GmbH)

a „Dimensions“on page 72

a „Technical data“on page 76

1*) Internal jumper

2*) Additional PE connection via contact spring on rear

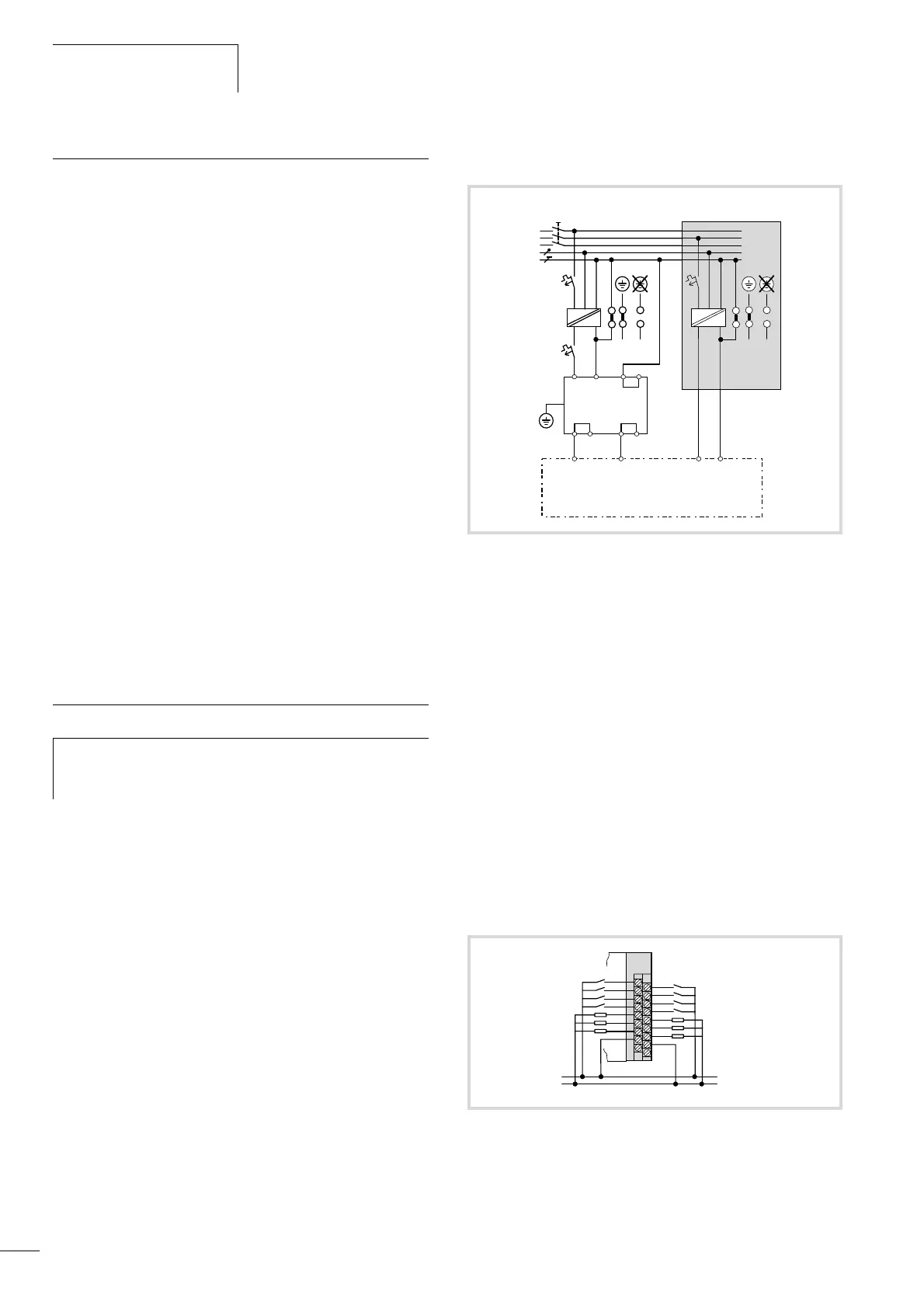

Figure 19: Example for wiring the terminal block

~

=

~

=

a

ed

f

ed

c

b

L1

L2

L3

N

PE

24 V

0 V DC 24 V

Q

0 V

Q

DC

XC-CPU101-CxxK-8DI-6DO

1*)

1*)1*)

XT-FIL-1

2*)

(Voltage supply of CPU101) (Voltage supply of the

local digital inputs/outputs)

+ 24 V

Q

H

0 V

Q

H

0

2

4

6

0

2

4

1

3

5

7

1

3

5

Loading...

Loading...