7

www.monitorproducts.com

For steady water temperatures, the DHW water flow rate

through the MZ25S must be high enough to keep the MZ’s

burner on. If the user complains of DHW temperature swings,

especially in the shower, install a thermostatic mixing valve

between the hot and cold legs of the system. Make sure it is

a thermostatic, not a tempering valve. Also make sure that

the temperature setting of the MZ25S is at least 15° above

the desired mix temperature of the thermostatic valve (even

if it means a higher than needed gpm valve is used), or there

may be temperature fluctuations.

NOTE: The DHW performance of the MZ25S is not exactly

like that of a regular hot water heater, so make sure that you

or your customer understand its limitations. Filling a bathtub

will take longer, since most wide open spigots will not yield

hot enough water for a comfortable bath. The filling process

will have to be slowed in order to keep the temperature up.

Make sure your customer knows this! If space is not critical,

it is almost always better to use an MZ 25C and one of our

BS tanks. The cost of the tank and valves are little more than

the difference between the 25S and 25C. It has been our

experience that those people who choose the MZ25S do so

for the exceptionally high efficiency for overall DHW as

compared to conventional standing-pilot, gravity-vented gas

water heaters, and easily adjust to the subtle differences.

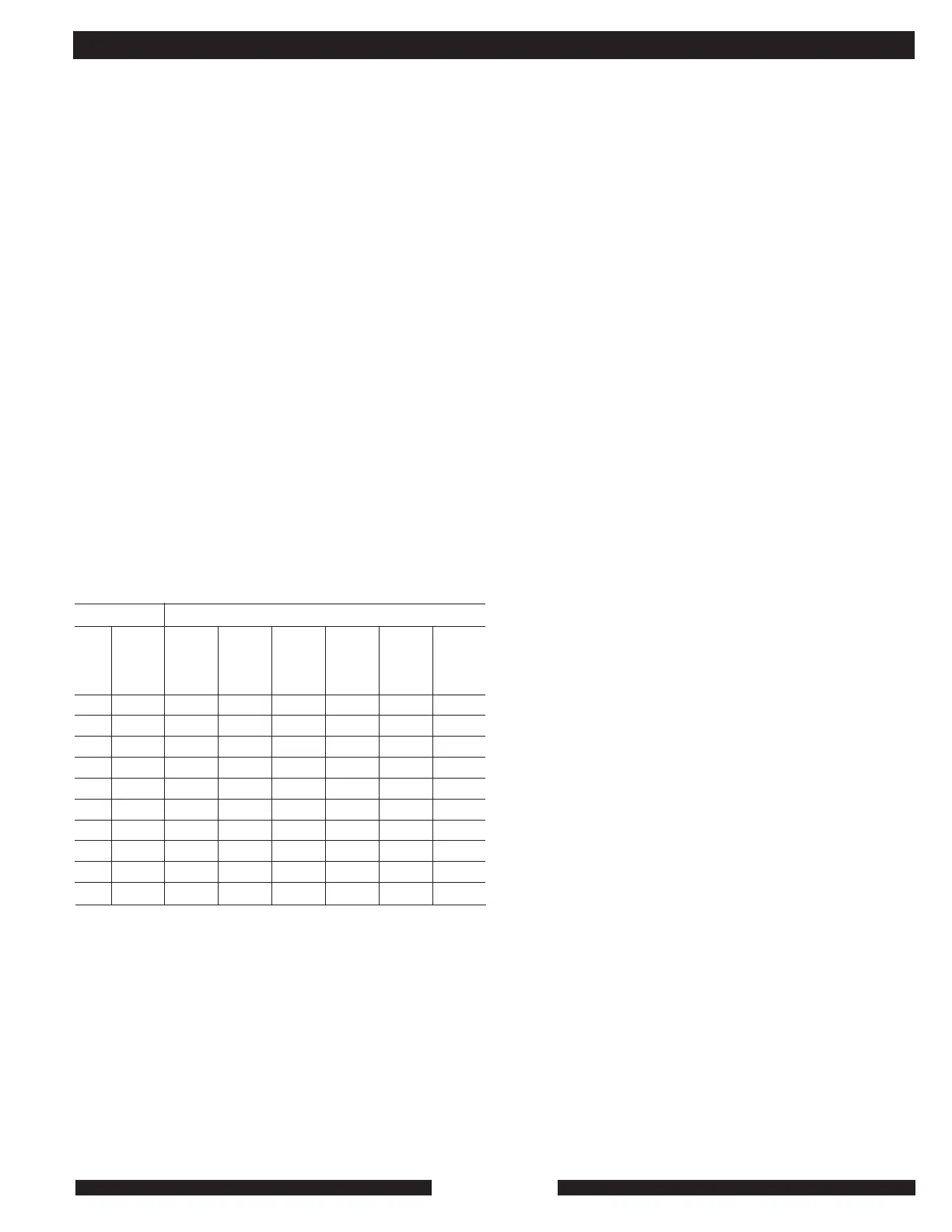

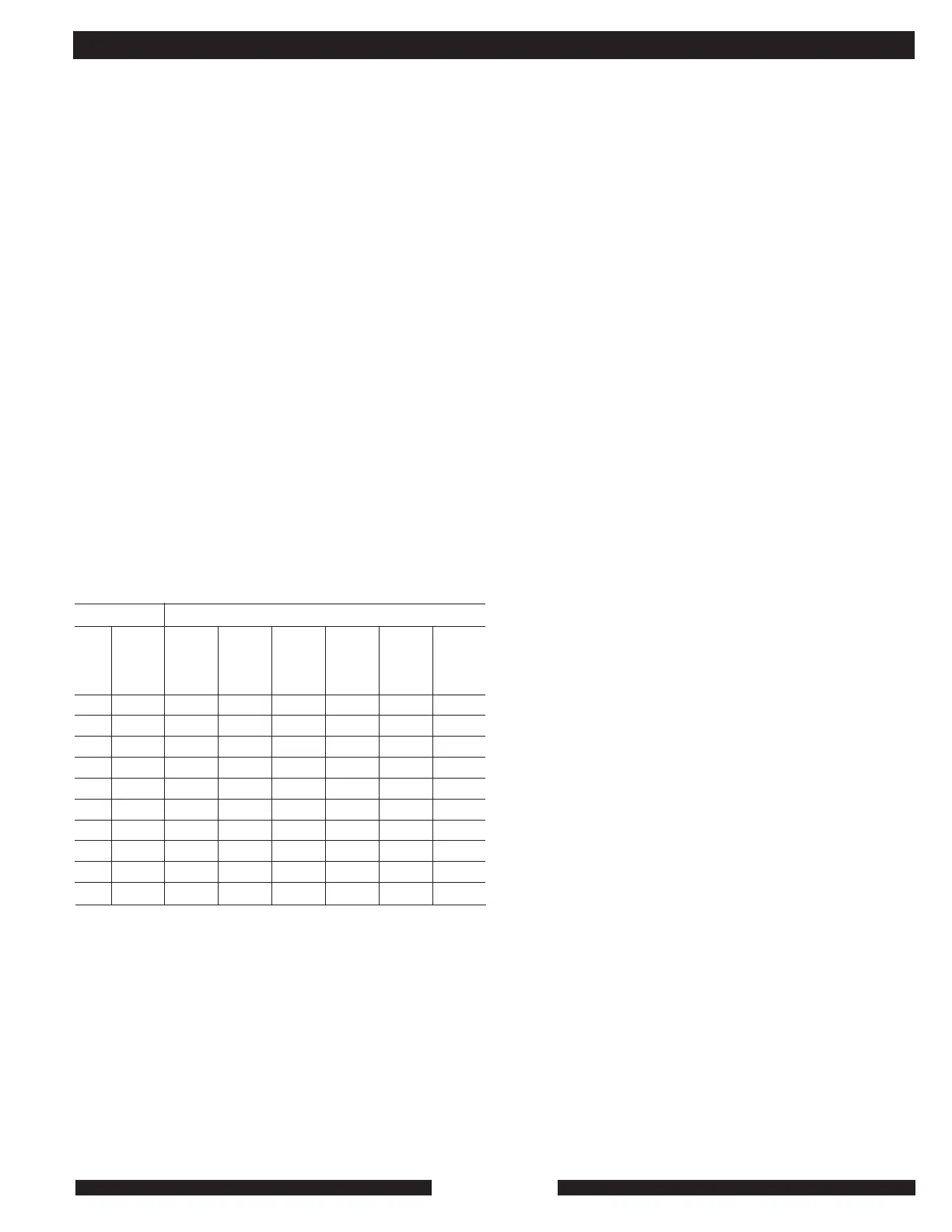

Table 1 may be helpful in balancing MZ25S DHW systems.

APPROXIMATE DHW PERFORMANCE OF MZ25S AT

VARYING FLOW RATES AND INLET WATER

TEMPERATURES. ALL TEMPERATURES ARE IN

FAHRENHEIT.

First column gives flow in gallon per minutes.

At any steady gallons per minute (GPM) flow rate, the MZ

will raise the temperature of the inlet water by a specific

amount. That temperature rise is shown in the second column.

Third, and subsequent columns, gives inlet water temperature

rising 5º F increments (top row) and the leaving domestic hot

water (DHW) temperature (remaining rows.)

GPM

1.5

1.75

2.0

2.25

2.5

2.75

3.0

3.25

3.5

3.75

Temp

Rise

105

90

79

70

63

57

52

48

45

42

35 F.

Inlet

Water

Temp

140

125

114

105

98

92

87

83

80

77

40 F.

Inlet

Water

Temp

145

130

119

110

103

97

92

88

85

82

45 F.

Inlet

Water

Temp

-

135

124

115

108

102

97

93

90

87

50 F.

Inlet

Water

Temp

-

140

129

120

113

107

102

98

95

92

55 F.

Inlet

Water

Temp

-

145

134

125

123

112

107

103

100

97

60 F.

Inlet

Water

Temp

-

-

139

130

128

117

112

108

105

102

Table 1

MZ25S Leaving water Temperatures, Degree F.

CONDENSATE:

Condensate removal can be accomplished by letting it drain

into the building’s normal drain or septic system. The MZ’s

condensate output depends on the return water temperature

of the heating system. Colder return water means higher

efficiency and more condensate. Over time condensate will

eat concrete, iron and copper drains. Most drain water is

alkaline which will neutralize condensate. Percolating

condensate through crushed limestone will neutralize it. If no

gravity drain available, an acid-proof condensate pump will

do the job.

CHARGING & LEAK TESTING:

It is assumed that the system into which the MZ is being

installed is a leak-free system. Leaks in the system will

damage the heating system and void the warranty. If there are

leaks in the system, fresh water will have to be added to the

system to replace the lost water. The addition of fresh water,

over time, will always bring air and dissolved minerals into the

heating system and will dilute the corrosion inhibitor. All of

which will cause a failure.

The proper concentration of BIONIBAL corrosion inhibitor (1%

by volume for all metal pipe systems and systems with oxygen

barrier tubing, 2% by volume for non-barrier systems) that is

shipped with the MZ will completely protect the MZ and the

system it is connected to from corrosion if kept at the right

strength. BIONIBAL does not deteriorate over time or get used

up over time. Additional Bionibal is available form MPI.

Once the system is properly charged with:

• Water

• BIONIBAL, or

• Water, glycol BIONIBAL mixture, it should remain stable

indefinitely.

Before the MZ is connected, the piping system should be

filled with clean, neutral P-h water to a pressure of 100 PSI. If

there is no change in pressure after 24 hours, the system

can be assumed to be leak-tight. The system should also be

visually inspected as thoroughly as possible. If any leaks are

found, they must be repaired.

The MZ has a brass, male-hose-thread, fill-and drain valve

operated by a stainless-steel ball valve. We recommend that

the MZ not be permanently piped to the structure’s potable

water system, unless local code requires auto fill. If auto-fill

is installed to the system, our recommendation is that it be

turned off. The flow switch in the MZ prevents low-water firing.

It is normal for heating systems to lose a very small amount

of water over time through valve stems or similar fittings. This

trivial amount of water can easily be replenished during normal

maintenance. There is a clear plastic tube in the MZ that fits

over the nozzle on the air vent and prevents the water that typically

spits out of the nozzle from staining the inside of the MZ.

On start up, the MZ should be run in the heating mode until

the entire system is brought up to operating temperatures.

Do not leave city water pressure on the auto-fill during normal

heating system operation since any system leaks will cause

the Bionibal corrosion inhibitor to be diluted and eventually

INSTALLATION AND TECHNICAL

Loading...

Loading...