9

www.monitorproducts.com

Important note about altitude: Since atmosphere thins

as altitude increases, there is less oxygen available to

support combustion at high altitude. The combustion-air

ALTITUDE ADJUSTMENT

1) Fire heating system. Let run for five minutes. Measure and

set CO at 30 PPM for natural gas (50 PPM for LP gas ).

There is a tapping in the vent elbow inside the MZ’s cabinet

just to the left of the flue-gas exit from the MZ for flue gas

measurement. Note that the cap that covers the gas valve’s

adjustment screw must be in place when CO measurement

is made.

2) Take cover off of air-pressure switch. With heating system

running, jump contacts so that heating system continues

to fire when switch opens.

3) Very, gradually block inlet air to blower with something light

and stiff, such as a credit card, until CO reads between

500 and 750 PPM. (NOTE: Blocking half of the blower

inlet may raise CO only slightly. As the critical point of

blockage is reached where CO does begin to ramp up, a

very small increase in blockage makes a very large

increase in CO. It is best to increase blockage VERY

slowly.) Remove jumper wire from switch. Burner will go

out and CO will begin to fall.

4) Adjust air pressure switch VERY, gradually counter

clockwise to the point where the switch closes, which will

then cause the burner to relight.

5) Unblock blower inlet air.

6) CO measurement should then return to 30 PPM for natural

gas ( 50 PPM for LP.) Check to verify that CO is normal.

7) Replace terminal cover on air-pressure switch, replace plug

in vent pipe, replace MZ cover. Cycle unit to verify normal

operation.

INSTALLATION AND TECHNICAL

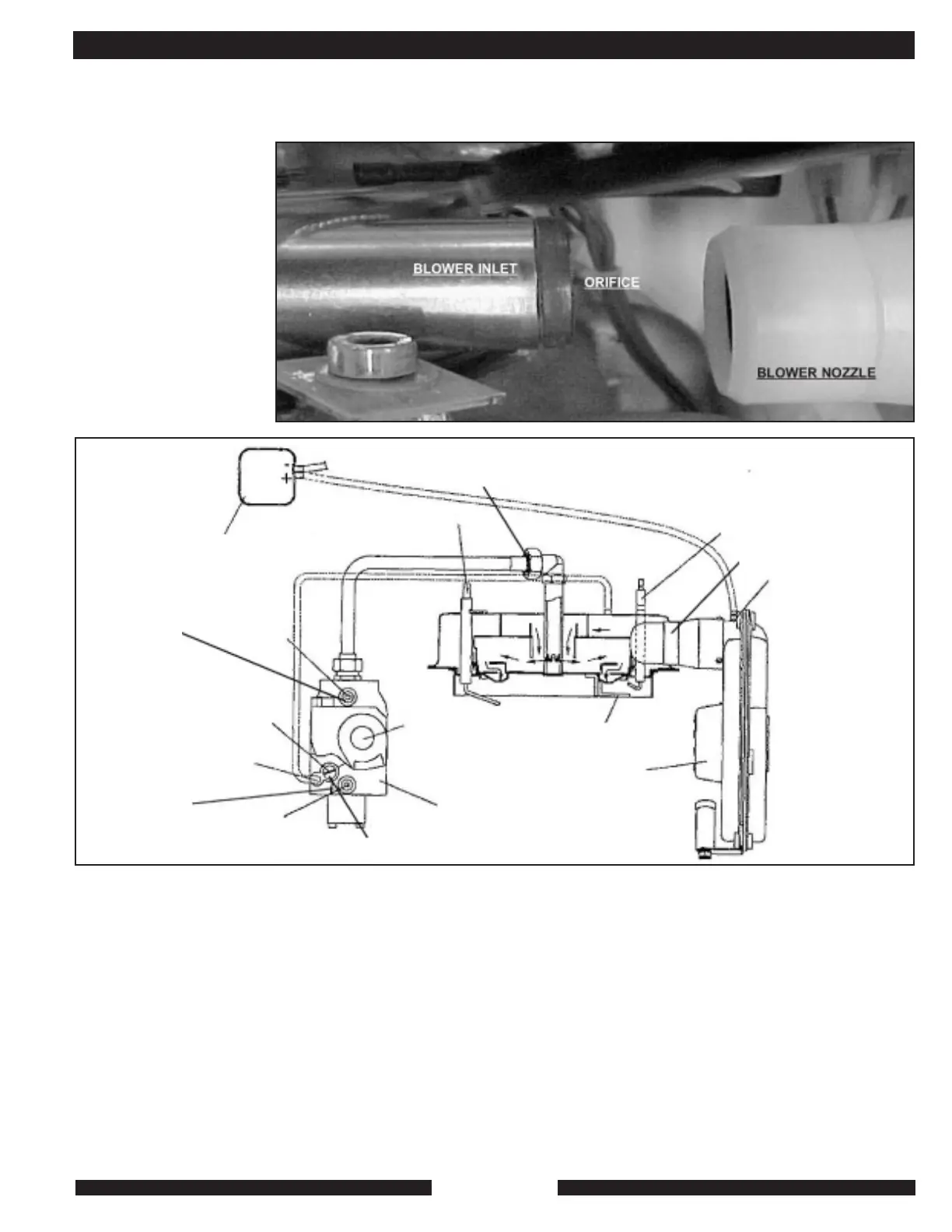

blower used on the MZ

was designed specifically

for the MZ. Its normal

operating speed is partly

determined by the density

of the air moving through

it. As altitude increases,

the MZ’s blower spins

easier and faster in-

Combustion Chamber

unit pressure

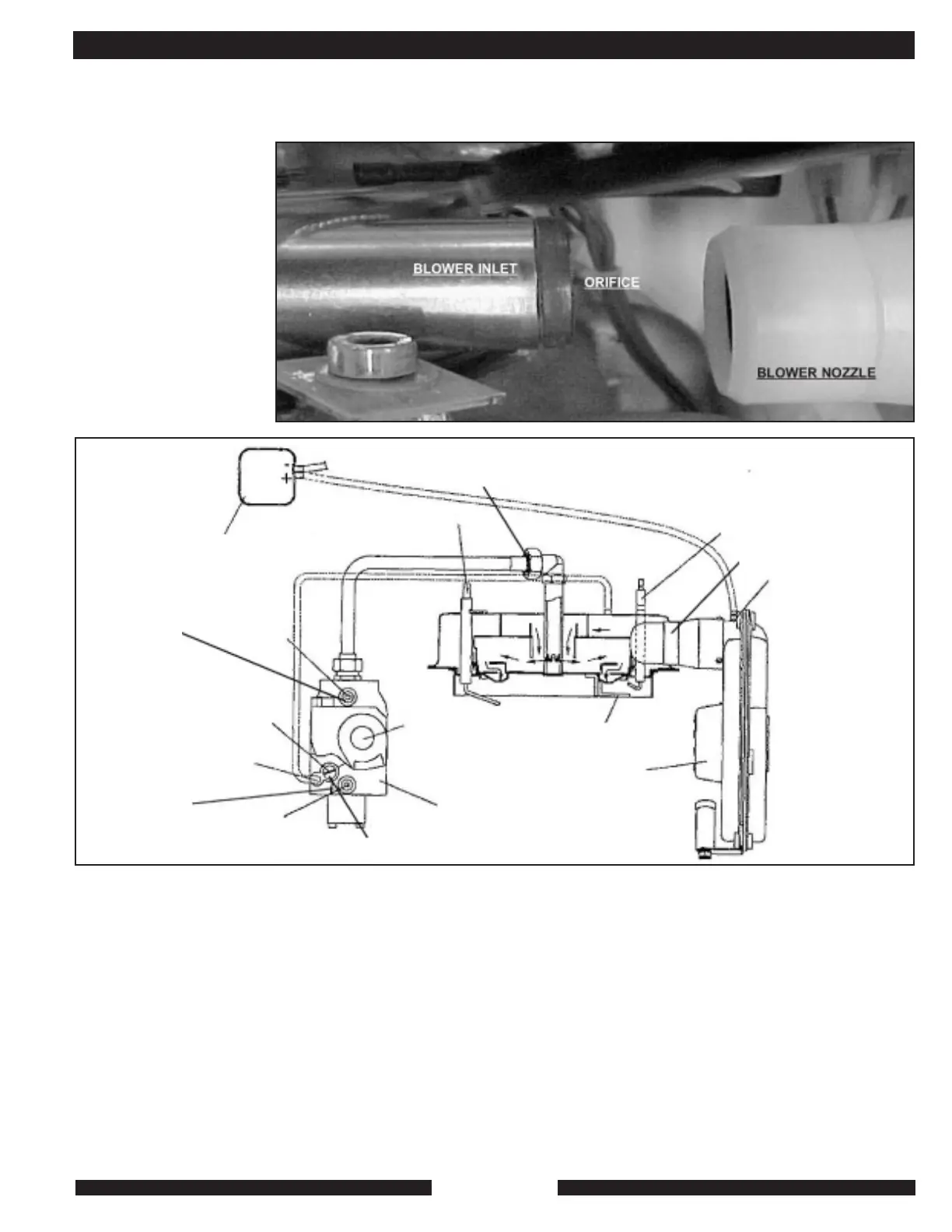

Gas orifice is located in gas-line side of union. Spray union with penetrating

oil and tap wrench to locate nut on union. Gas line may need to be reamed

to accept LP orifice for MZ40.

Air pressure switch

Ionization probe

Outlet pressure

MZ25 Nat. 2.8

MZ25 LP 5.5

MZ 40 Nat or LP 2.8

Pressure

Tap P2

Gas

pressure

regulator

Servo-

system

Pressure

Tap P1

Solenoid

Inlet pressure

must stay within 5”

and 7” WC for

Natural Gas and

11” and 13” WC

for LP gas

Gas valve

To avoid pressure, remove cap, turn adjustment screw

clockwise to increase, counter clockwise to decrease.

Cap must be on to measure.

Ignition accelerator

Air fan

Ignition electrode

Air orifice location

Air pressure switch

test point

creasing the amount of air. The MZ can be used up to 6,000

feet dependinc on vent length of run, aAbove 6,000 feet,

adjustment of the air-pressure switch is necessary.

ALTITUDE

ADJUSTMENT

DIAGRAM

Loading...

Loading...