8

MZ INSTALLATION & MAINTENANCE

eliminated. Oxygen and minerals in the water coming in to

replace the water leaking out will damage the MZ.

CORROSION:

The MZ should be filled with clean, clear, neutral ph water

suitable for drinking. A cleaning solution such as a mixture of

water and trisodium phosphate should be used in any systems

with oily residues. Many chemicals have been used over the

years in existing heating systems that could cause

premature failure of MZ units. It is important that no additives

be used in the system water for the MZ other than BIONIBAL,

which is supplied with each unit.

IMPORTANT: The use of a 2% by volume solution of

BIONIBAL in a radiant-heating system using non-oxygen-

barrier tubing will protect the MZ and the system to which it is

connected, from oxygen corrosion. In a system using tubing

with an effective, intact, oxygen barrier or in a hard-piped

system, a 1% solution of BIONIBAL is sufficient. BIONIBAL

doesn’t deteriorate or weaken over time, but should be

renewed if system is drained.

Under no circumstances should standard commercial anti-

freeze solutions be used in the MZ. Most of them contain

corrosion inhibitors that are not approved for use in the MZ.

They will cause heat exchanger failures that are not covered

by warranty. No other additives for lubrication, leak stoppage

or any other purpose can be used in the MZ. To do so will

void all warranty.

FREEZE PROTECTION:

In situations where freeze protection is a necessity. MPI ships

5 gallon quantities of BIONIBAGEL anti-freeze which is

formulated with Bionibal at a concentration that will bring a

50/50 mix of BIONIBAL and water to a 1% concentration of

BIONIBAGEL. If the application does not require a 50/50 mix,

the addition of sufficient BIONIBAL to bring the resulting

solution to a 1% concentration is important, otherwise bacterial

growth and corrosion may take place. In non-barrier systems,

which we discourage, a 2% concentration of BIONIBAL must

be assured. One quart (part # 9526) and 2.6 gallon (part

#9519) quantities of BIONIBAL are available from MPI.

Note that the addition of glycols to the water passing through

the MZ changes the rate at which the mix absorbs and

releases heat, decreasing its effectiveness as a heat transfer

fluid. Glycols also increase the viscosity of the water, making

it more difficult to pump. These factors can significantly

influence the overall performance of the heating system and

should be taken into account in the system’s design.

in an easily accessible place. The pipe supplying gas to the

heating system must not cause a pressure loss great enough

to decrease inlet gas pressure below the specified minimum

gas pressure values. (5" of water column for natural gas, 11"

for LP.) After initial start up, check that the pressure tapping

points are properly closed and check the general leak

tightness of the gas circuit. Always purge through the gas

pipe work before initial firing of the unit (in order to get rid of

any particles produced by welding or threaded joints).

The unit and its individual shut-off valve must be disconnected

from the gas supply piping system during any pressure testing

of that system.

NOTE: Many commonly used,

unapproved corrosion inhi-

bitors CAN DAMAGE THE MZ

AND VOID THE WARRANTY.

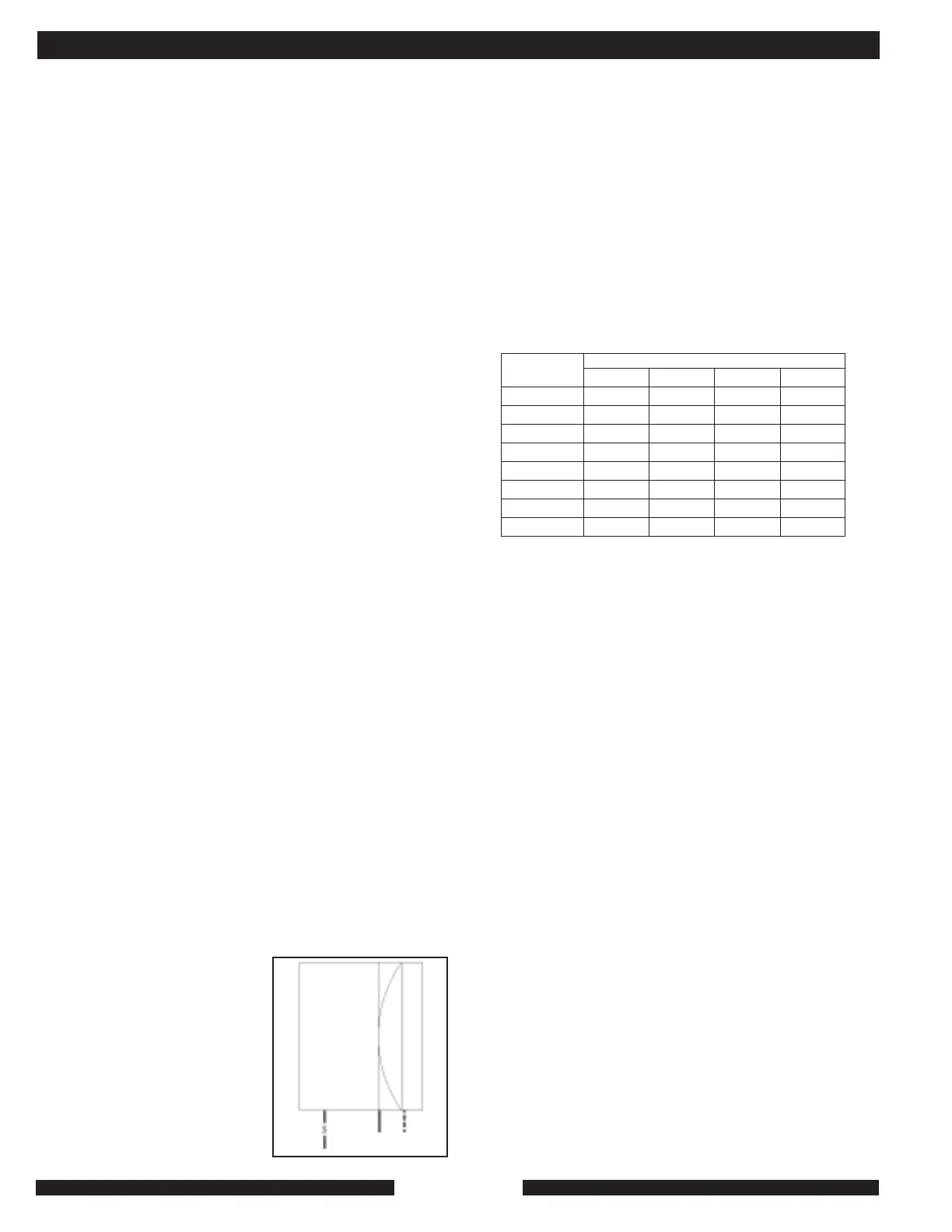

GAS PIPING:

The supply line is 3/4" NPT, and

enters at the lower left side of the

unit as shown.

The gas supply pipe must be fitted

with a 1/ 4 turn stop valve located

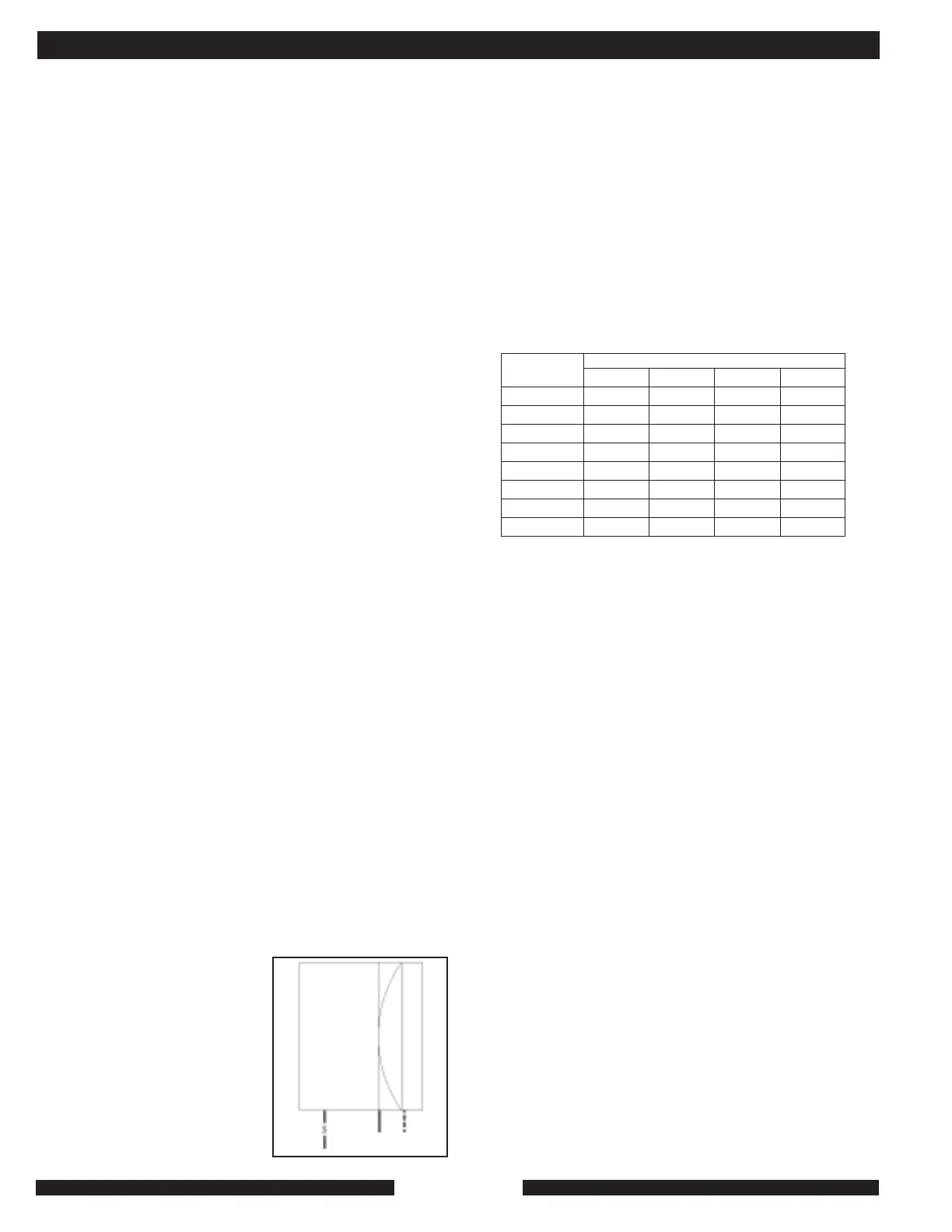

EXAMPLE PIPE SIZING TABLE

For gas flow through various pipe lengths and diameters.

(FOR REFERENCE ONLY)

Note: Table above is for natural gas with specific gravity 0.60

with a pressure drop through the gas piping of 0.30" w.c. Refer

to ANSI Z223.1 for additional pipe sizing.

Pipe length

(feet)

10

20

30

40

50

75

100

150

1/2"

132

92

73

63

56

45

38

31

3/4"

278

190

152

130

115

93

79

64

1"

520

350

285

245

215

175

150

120

1 1/4"

1050

730

590

500

440

360

305

250

Capacity of pipe for pipe size (ft3/hr)

NATURAL GAS TO LP GAS CONVERSION AND

HIGH ALTITUDE ADJUSTMENT:

Each MZ is supplied with a LP conversion kit. Follow steps

for conversion from Natural gas to LP:

1. Loosen the nut from the gas line/burner junction as shown on

next page (there are 2 on the MZ40C). Insert orifice into gas

line. Note that since there is no natural gas orifice in the MZ40C,

the tightening of the union between the gas line and the elbow

sometimes narrows the opening in the gas line for the orifice.

If that occurs, ream the opening. For MZ40C LP heating

systems, insert orifices before mounting heating system.

2. Reconnect nut and tighten.

3. For MZ25C/S models only: Remove the combustion air

fan by pulling it to the right. Disconnect the rubber air hose

and the wiring. Set the fan aside. Note: The split-ring LP

orifice slips into the burner, as shown below. If it fits loosely,

use the appropriate tool to open the split-ring LP orifice so

that it holds in place.

4. Inlet gas pressure for LP gas must be between 11" and 13"

water column with the heating system running. The MZ40C

requires no gas valve change. The MZ25C/S requires a gas

pressure adjustment from the factory 2.8" water column

setting to 5.5". The adjuster is under the slotted cap on the

gas valve. Turn the adjustment screw underneath the cap

full clockwise and then back off one turn counter-clockwise.

Replace cap. The heating system should then fire, permitting

outlet pressure measurement. Repeat adjustments until the

correct outlet pressure of 5.5" is reached. The final pressure

reading at tap P2 must be taken with the unit running and

the cap reinstalled on the gas valve.

INSTALLATION AND TECHNICAL

MZ

Heating

System

ÍGas Inlet

Loading...

Loading...