FG038 MK2 Divider RevA19 13-02-19

o Discharge conveyor turns but main machinery

does not rotate.

ISOLATE MACHINE FROM MAINS SUPPLY.

CHECK THE FOLLOWING:

1. Check slipping clutch.

NOTE: IF SLIPPING CLUTCH HAS OPERATED, IT MEANS THAT THE

DIVIDER MOTOR HAS BEEN OVERLOADED DUE TO JAMMING

OF THE DIVIDING HEAD MACHINERY.

2. Check Machine has oil in divider head and in tank.

3. Check oil drip feed is turned on

4. Open hopper canopy. Check in Hopper (5) for any object that could be

jamming machine. If a foreign object is jammed in divider components:

Call out MONO service contractor.

DO NOT ATTEMPT TO REMOVE IT, AS THE COMPONENTS MAY BE UNDER

TENSION. RELEASING THE OBJECT \MAY CAUSE COMPONENTS TO MOVE,

TRAPPING THE OPERATOR’S HAND.

5 Check machine is in a CLEAN condition.

NOTE: IF MACHINE HAS NOT BEEN CLEANED FROM PREVIOUS DAY,

DOUGH WILL “SET” AND THE FORCE REQUIRED TO MOVE

DIVIDING MACHINERY WILL OVERLOAD MOTOR, OPERATING

THE SLIPPING CLUTCH.

6 If the above has happened: Care must be taken when removing the

components as it is possible they are under pressure caused by expansion of

the dough.

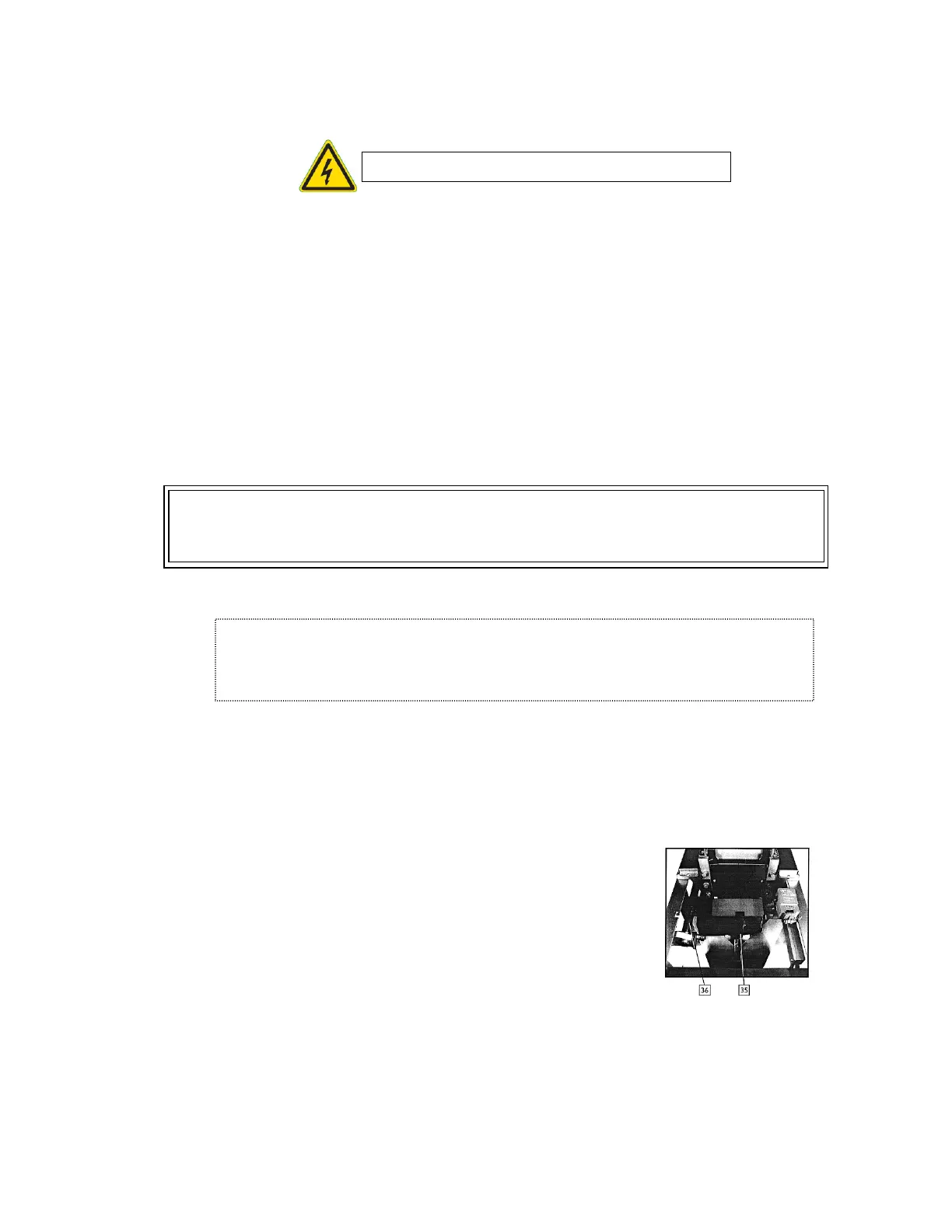

7 Take special care with ejector piston (35), as moving ejector piston actuating

arm (36) will release the ejector piston, which if under pressure will be

propelled outwards and could cause serious injury.

8 Thoroughly clean divider, visually checking parts for damage and distortion.

9 Oil parts.

10 Re-assemble.

11 If problem persists call Mono service dept.

Loading...

Loading...