SECTION 6: DUCT CONNECTOR INSTALLATION

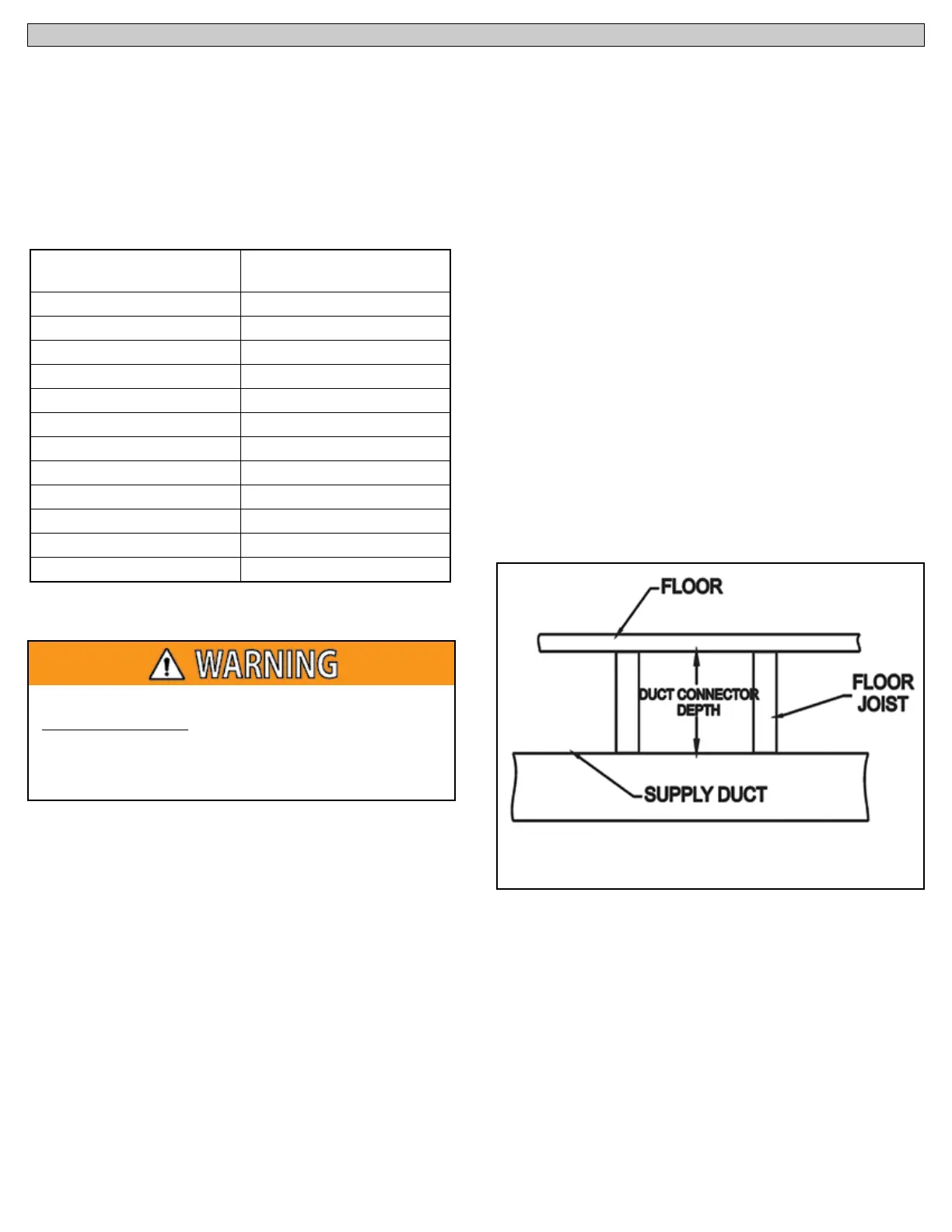

D E P T H F R O M F L O O R

T O D U C T - i n ( m m )

D U C T C O N N E C T O R

M O D E L N U M B E R

1 i n ( 2 5 .4 m m ) 9 0 - D C U O - 0 1

2 i n ( 5 0 .8 m m ) 9 0 - D C U O - 0 1

3 i n ( 7 6 .2 m m ) 9 0 - D C U O - 0 1

4 i n ( 1 0 1 .6 m m ) 9 0 - D C U O - 0 1

5 i n ( 1 2 7 .0 m m ) 9 0 - D C U O - 0 2

6 i n ( 1 5 2 .4 m m ) 9 0 - D C U O - 0 2

7 i n ( 1 7 7 .8 m m ) 9 0 - D C U O - 0 2

8 i n ( 2 0 3 .2 m m ) 9 0 - D C U O - 0 2

9 i n ( 2 2 8 .6 m m ) 9 0 - D C U O - 0 3

1 0 i n ( 2 5 4 .0 m m ) 9 0 - D C U O - 0 3

1 1 i n ( 2 7 9 .4 m m ) 9 0 - D C U O - 0 3

1 2 i n ( 3 0 4 .8 m m ) 9 0 - D C U O - 0 3

Duct Connectors

90-DCU0-XX Duct Connectors

A duct connector is used to provide a sealed connection

between the furnace base and a below the floor supply duct

system. The duct connector allows the furnace to be installed

on a combustible floor without the use of a separate sub-base

providing insulation is placed between the duct connector and

the combustible floor. Table 5 shows the duct connector needed

for various applications.

MORTEX PRODUCTS INC. 501 TERMINAL RD FORT WORTH, TX 76106 Page 7

Table 5: Duct Connector Models

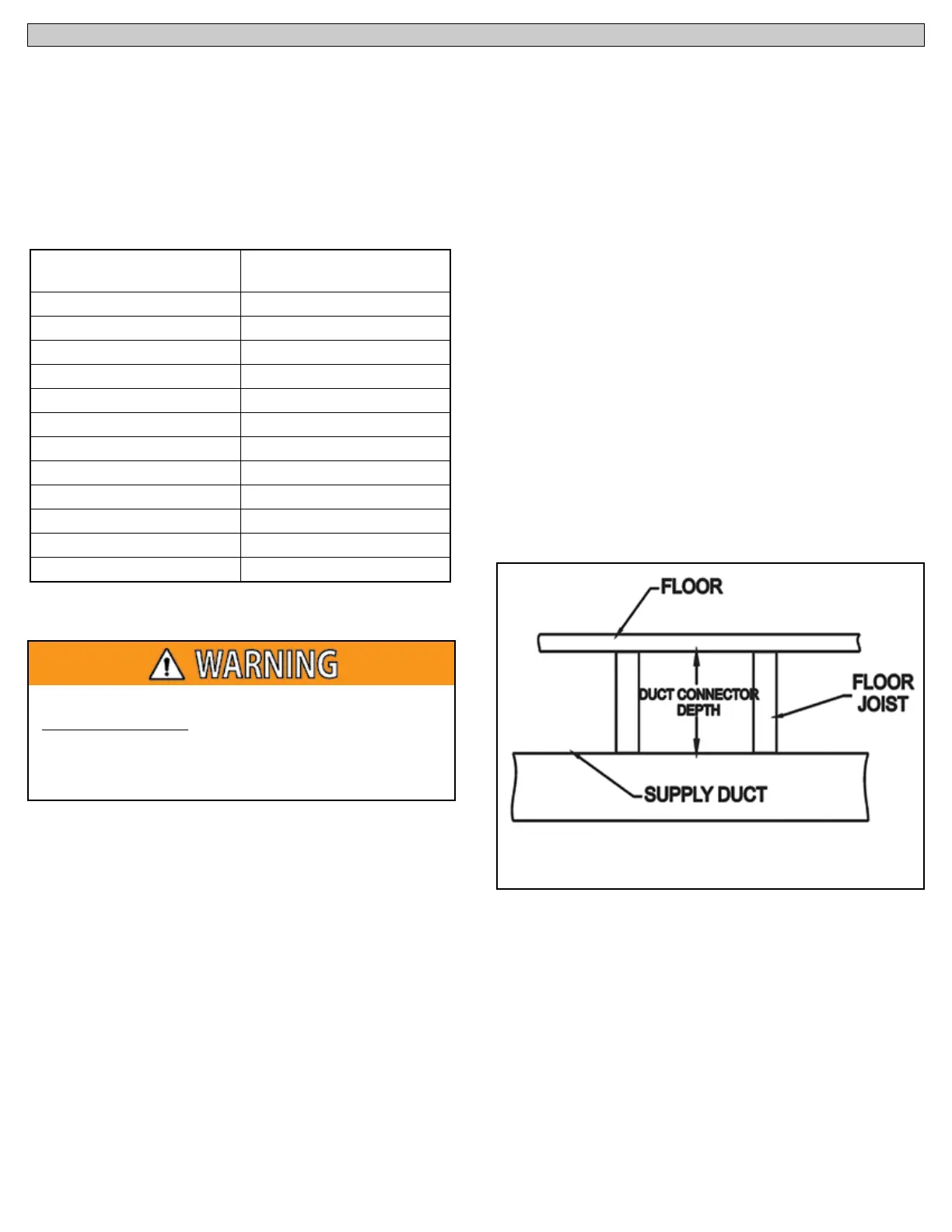

Figure 8: Duct Connector Depths

A duct connector can be installed on combustible flooring

except for carpeting. It is recommended to use insulation

having a rating of R-12 or higher between the floor base

and the combustible floor to prevent the combustible floor

from getting too hot.

Installing the Duct Connector

1. Refer to Figures 8 – 11 for dimensions necessary for duct

connector installation.

2. Attach the four (seal-strip) foam tape gaskets provided with the

duct connector around the perimeter of the duct opening in

the main supply duct trunk to seal between the duct

connector and the top of the duct opening.

3. Insert the duct connector through the opening in the floor

and attach the duct connector to the top of the main trunk

by inserting the tabs through the opening in the top of the

duct and bending the tabs back 90 degrees against the inside

of the duct. Confirm the seal-strip has sealed the area around

the duct connector where it attaches to the main supply duct

trunk.

4. Slit the corners of the duct connector that extend above the

floor and then bend the sides over onto the floor surface.

5. It is recommended to place insulation between the floor base

and the floor when used on a combustible floor to prevent the

combustible floor from getting too hot. Cut the insulation

around the perimeter of the duct connector opening.

6. Install the floor base over the floor opening with the flanges in

the opening facing downward.

7. Insert the four screws provided in the kit through the four holes

in the floor base and drive the screws into the floor to secure

the floor base to the floor.

Additional Duct Connector Installation Information

The duct connector is designed to be installed in place of an

existing duct connector and is designed for use on ducts wider

than 12 inches (304.8mm). When using the duct connector on

narrower ducts, there will be insufficient clearance to bend the

tabs on four sides of the duct connector. Some of the tabs on

the duct connector may need to remain unbent so it fits into

the main trunk. In these cases, the tabs may be attached to the

sides of the main trunk by using sheet metal screws or other

suitable fasteners. Add holes in the tabs for sheet metal screws

by drilling the required screw holes in 3 tabs on each side of the

duct connector. If more than three tabs are needed to provide a

more secure and air-tight connection, drill the remaining tabs so

the additional tabs can also be fastened to the duct with screws.

Use a duct sealer to seal any air leaks between the duct and the

duct connector. High temperature metal tape can also be used

to provide an air seal. The tape should be approved by applicable

national or local codes.

Loading...

Loading...