4 Commissioning

Maschinenfabrik Reinhausen GmbH 2020 315788897/03 EN VACUTAP

®

VVS

®

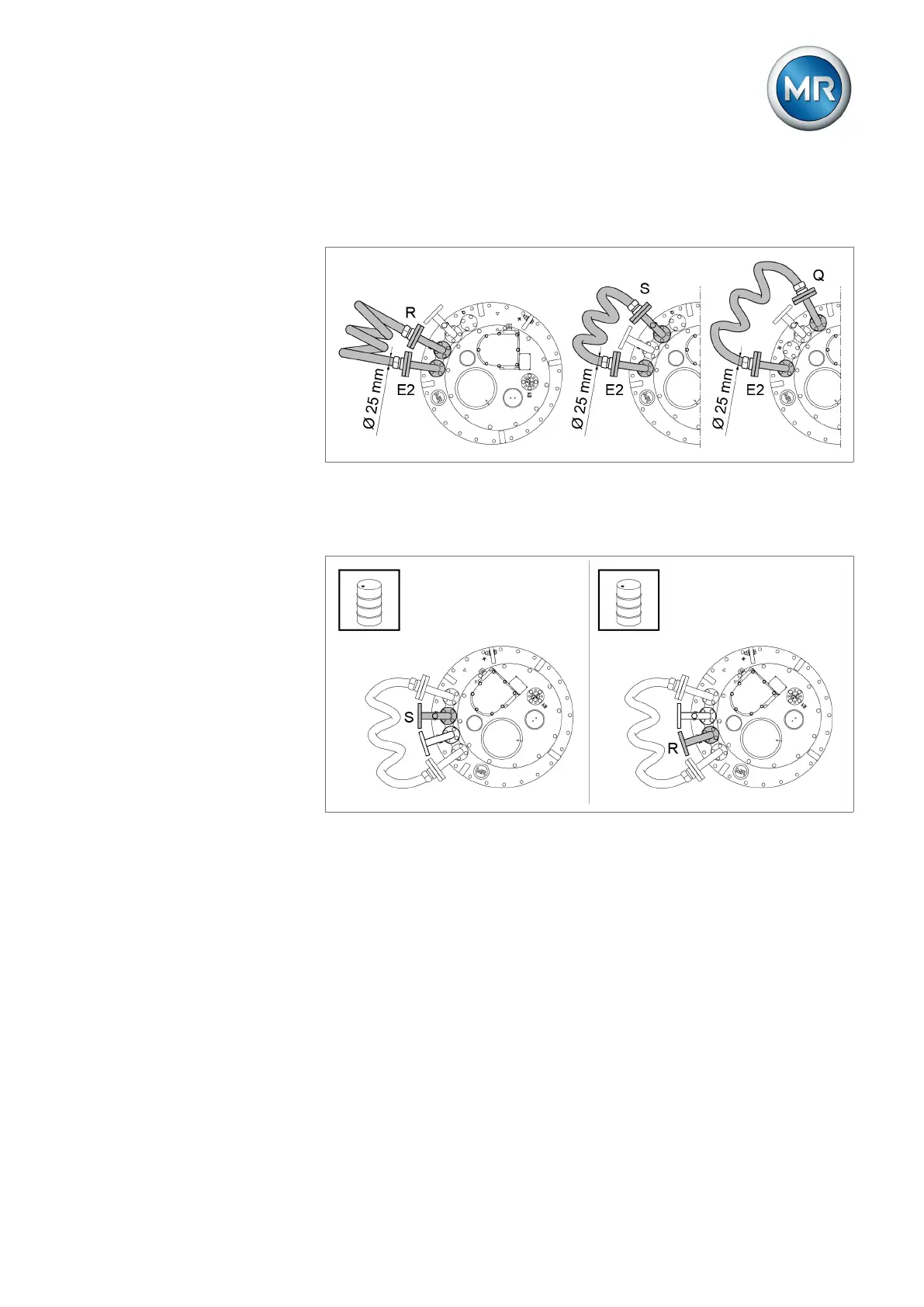

2. Establish a connecting lead between pipe connection E2 and one of the

pipe connections R, S or Q to ensure equal pressure in the oil compart-

ment and transformer during evacuation.

Figure16: Connecting lead

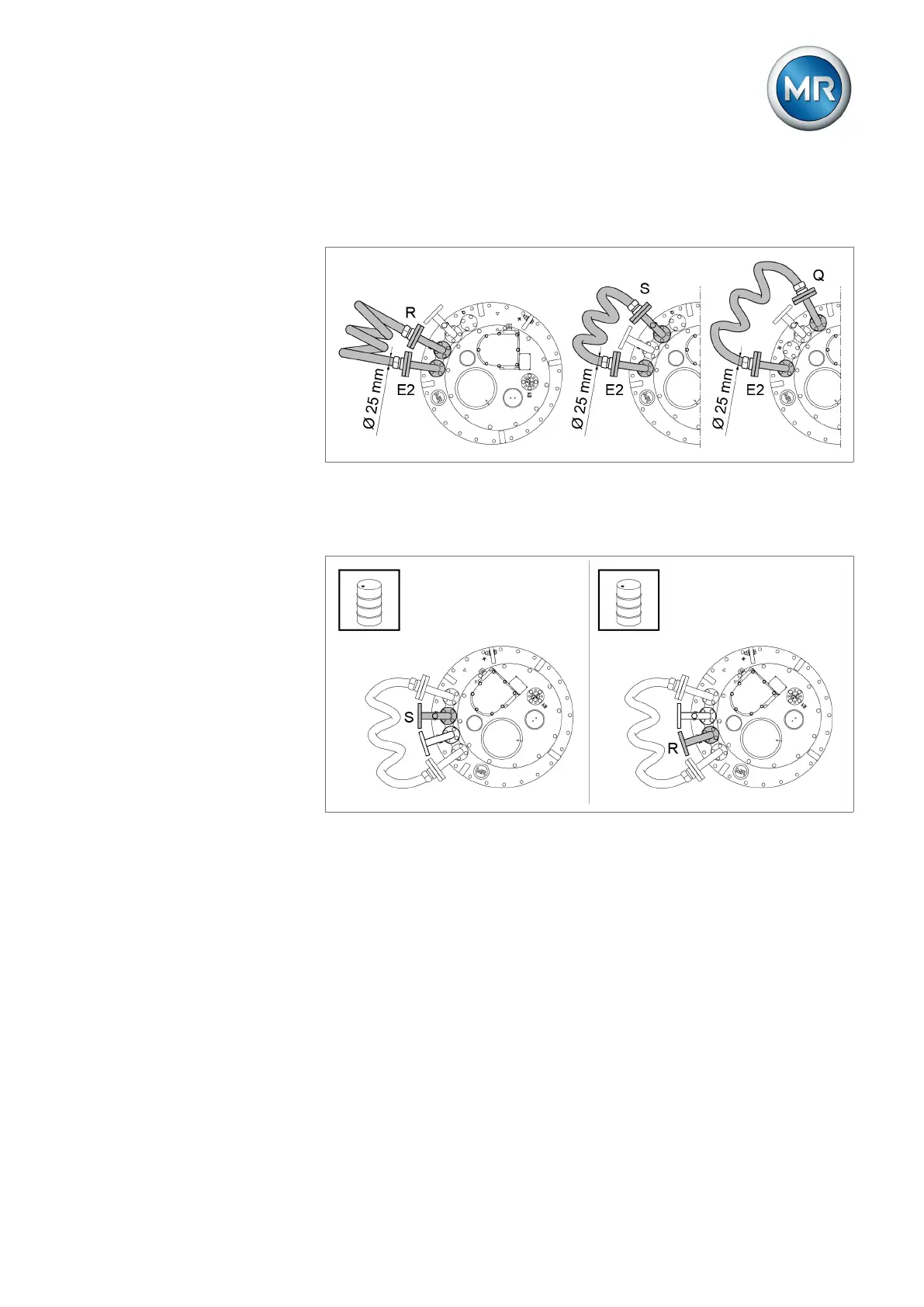

3. Fill on-load tap-changer with new mineral insulating oil for transformers in

accordance with IEC 60296 using one of the two free pipe connections of

the on-load tap-changer head.

Figure17: Pipe connections S and R

4. Take oil sample from oil compartment.

5. Record temperature of oil sample just after sample is taken.

6. Determine dielectric strength and water content at a diverter switch oil

temperature of 20 °C ± 5 °C. The dielectric strength and water content

must comply with the limit values provided in the appendix.

7. Bleed the on-load tap-changer.

8. Perform trial tap-change operations.

4.1.2 Bleeding on-load tap-changer head and suction pipe

4.1.2.1 Bleeding on-load tap-changer head

1. Open all forward and return valves in the pipe system.

Loading...

Loading...