BASIC TROUBLESHOOTING

16

Repairing the problem

The third step in the troubleshooting process is to

repair the problem. This step consists of:

1. Form a diagnosis by using all of the information

gathered from the troubleshooting that was per

-

formed.

2. Physically perform the repair.

The fourth, and hopefully final, step in the trouble-

shooting process is the follow through. This step con-

sists of:

1. Thoroughly test the repaired equipment: con-

firming that the initial diagnosis was correct. If it

was wrong, start the troubleshooting process

over again.

NOTE: Sometimes the engine will have multiple

problems at the same time. By performing one

repair, other issues may show up that are unre

-

lated to the first repair.

2. Delivery to customer: We are not just repairing

equipment, we are repairing customers.

A Inoculate against recurring problem with

education, e.g..: if the problem was caused

by stale fuel, make sure the customer is

aware that fuel goes bad over time.

B Make sure the customer understands the

repair, preventing “superstitious” come-

backs.

Prime test

To perform a prime test:

1. Prime the engine through the carburetor throat

using a squirt bottle, filled with clean fresh gaso

-

line.

2. Make sure the throttle is in the run position and

the safety key if fully inserted.

3. Attempt to start the engine.

4. If the engine starts and runs long enough to burn

the prime, the problem is effectively isolated to

the fuel system. proceed to Chapter 4: The Fuel

System and Governor.

5. Check ignition system as described in Chapter

7: Ignition System.

6. If the ignition system is working, check the com-

pression or perform a leak down test.

Leak-down test

A leak-down test is the preferred method to test the

engine’s ability to compress the charge. It will also

show where pressure is leaking from.

To perform a leak-down test:

NOTE: A leak down test pressurizes the com-

bustion chamber with an external air source and

will allow the technician to listen for air “leaking “

at the valves, piston rings and the head gasket.

NOTE: These are general instructions. Read

and follow the instructions that came with the

tester before attempting to perform this test.

• If possible, run the engine for 3-5 minutes to

warm up the engine.

• Remove the spark plug and air filter.

• Find top dead center of the compression stroke.

1. Find top dead center by following the steps

described in the valve lash section of Chapter 1:

Introduction

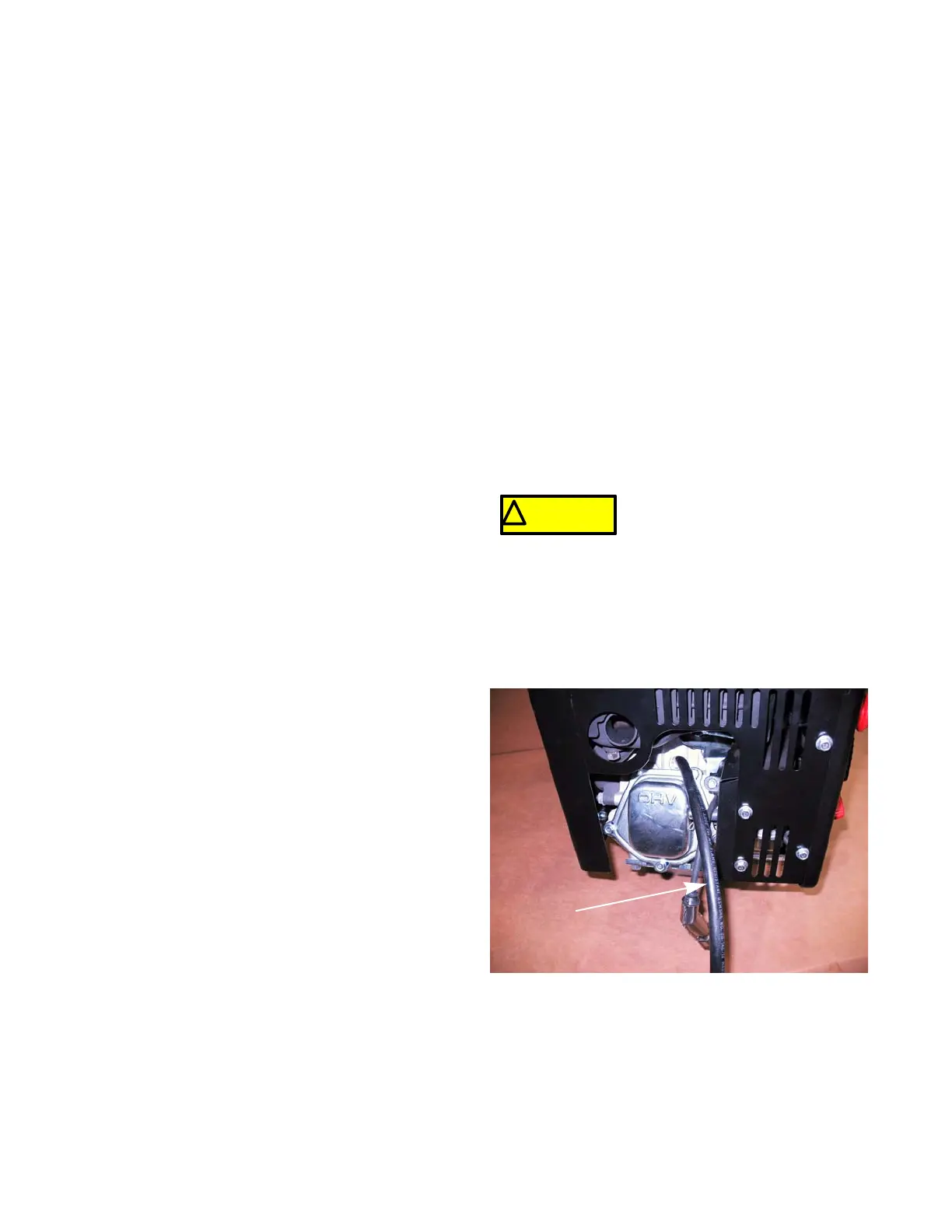

2. Thread the leak down tester adapter into the

spark plug hole.

See Figure 2.1.

! CAUTION! CAUTION

If the engine is not centered at top

dead center, the engine will rotate

when compressed air is introduce

to the combustion chamber.

Figure 2.1

Leak-down

tester adapter

Loading...

Loading...