BASIC TROUBLESHOOTING

17

3. Connect tester to compressed air.

4. Adjust the regulator knob until the needle on the

gauge is in the yellow or set area of the gauge.

5. Connect the tester to the adapter.

NOTE: If the engine rotates it was not at top

dead center.

6. Check the reading on the gauge.

7. Compare the results to the following chart. See

Table 1.

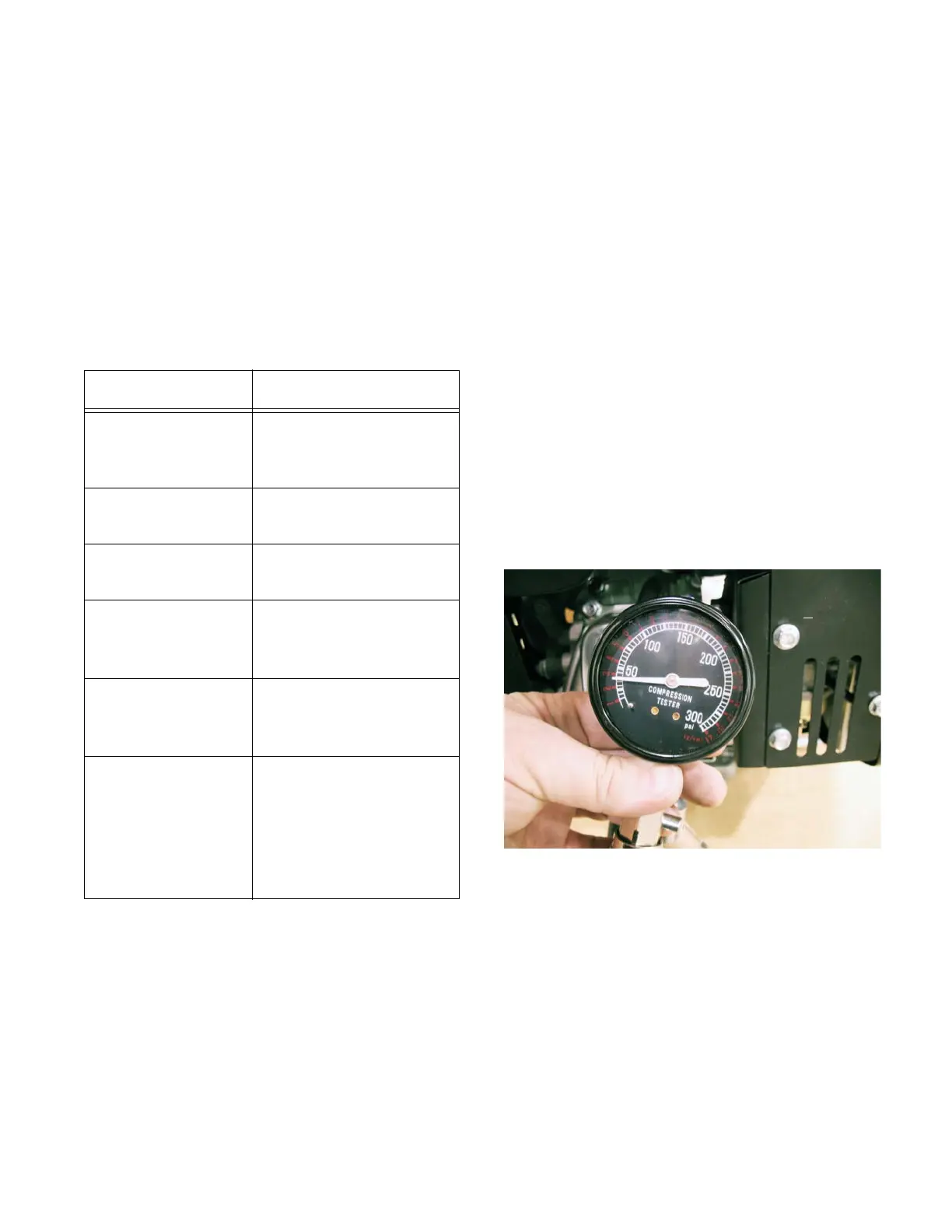

Table 1:

Symptom Possible cause

Air escaping from

the breather

Worn cylinder or pis-

ton rings. Possible

blown head gasket

Air escaping from

the exhaust

Leaking exhaust valve

Air escaping from

the carburetor

Leaking intake valve

Gauge reading

low

Cylinder and piston

rings are in good con-

dition

Gauge reading

moderate

There is some wear in

the engine, but it is still

usable

Gauge reading

high

excessive wear of cyl-

inder and/or piston

rings. Engine should

be short blocked or it

could be a blown head

gasket.

Compression test

To perform a compression test:

NOTE: Compression should be in the range of

40-75 PSI (2.8-5.2 Bar).

• Disconnect the high-tension lead from the spark

plug and ground it well away from the spark plug

hole.

• Remove the spark plug using a 13/16” or 21mm

wrench. A flexible coupling or “wobbly” exten-

sion may help.

• Pull the starter rope several times to purge any

fuel or oil from the combustion chamber.

NOTE: Air compresses readily, liquid does not.

Liquid in the combustion chamber will result in

an artificially high compression reading.

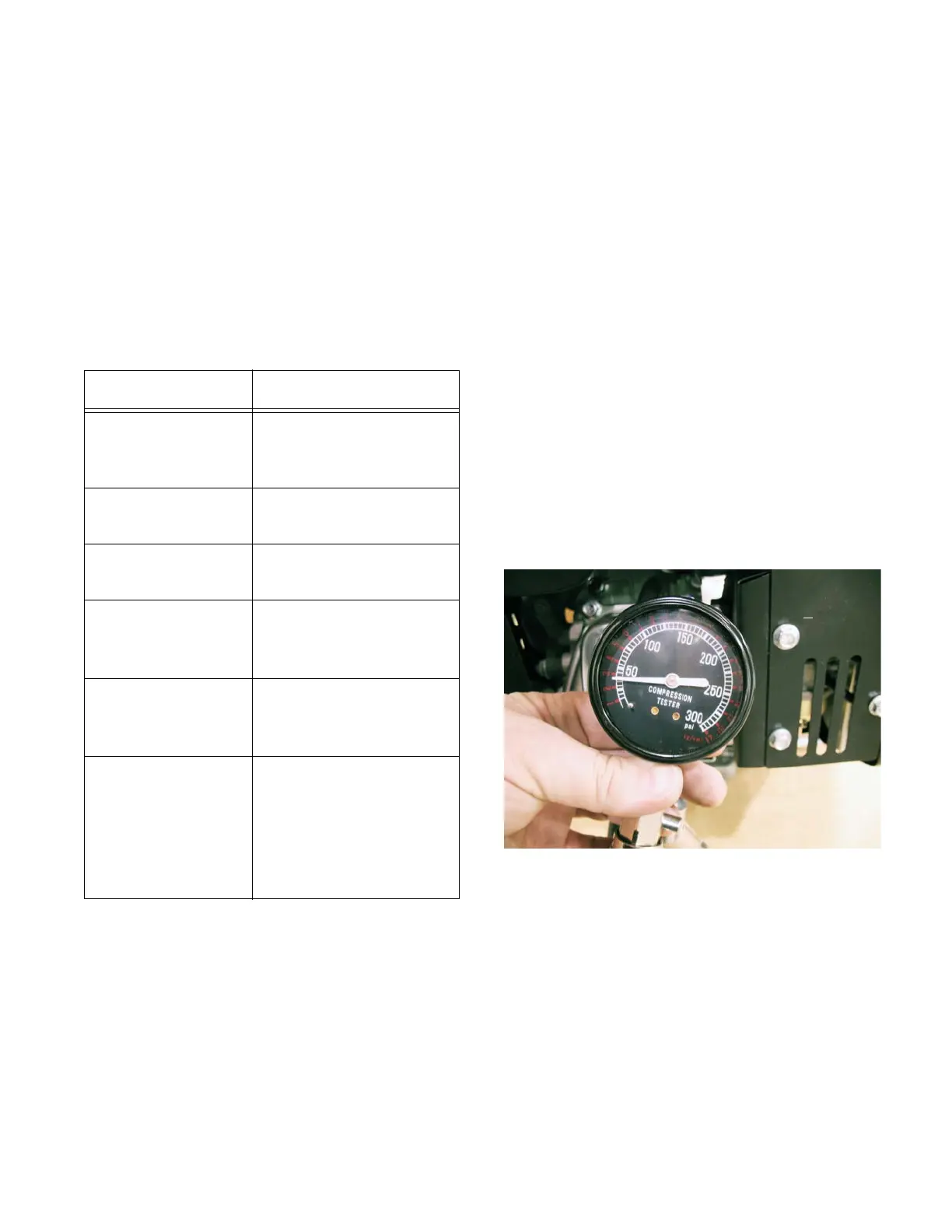

1. Install a compression gauge in the spark plug

hole.

2. Confirm that the gauge is “zeroed”, then pull the

starter rope repeatedly, until the needle on the

gauge stops rising.

See Figure 2.2.

Figure 2.2

Compression gauge

Reading ~

40 PSI

Loading...

Loading...