7.21 Universal Shaft

7.21.1 Universal shaft – Greasing

Preconditions

☑ Engine is stopped and starting disabled.

Special tools, Material, Spare parts

Designation / Use Part No. Qty.

Lithium-soap greases according to DIN2–KP K–20

CAUTION

Damage to component.

Serious damage to plant!

• Never press grease in at high pressure or with short, sharp movements.

• Maximum admissible greasing pressure: 15 bar.

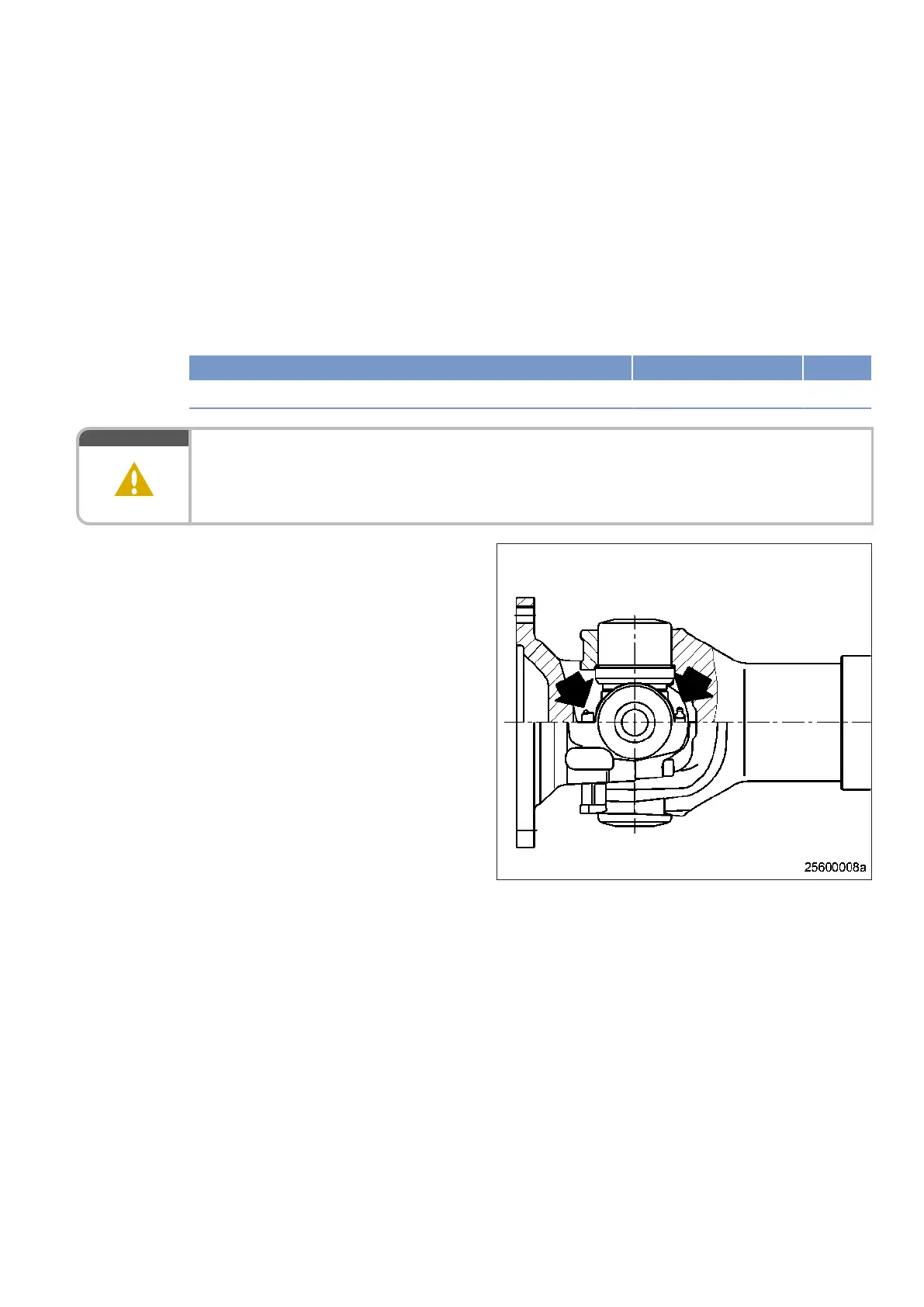

Universal shaft – Greasing

1. Remove guard from universal shaft.

2. Clean the two grease nipples on each joint

half.

3. Press grease into all nipples until it emerg‐

es at the star seals and sealing rings.

4. Reinstall guard.

MW15407/14E 2012-02 | Task Description | 143

TIM-ID: 0000007659 - 002

Loading...

Loading...