2202L5JE-DA-C5-N_2015.05.

7 Related Documents

Compound 2-stage Screw Compressor 7.3 Tightening Torques for Bolts and Nuts

1612LSC Speed Increaser Type

7-10

Locknut

P/N Tightening point

Tightening torque

N·m

Qty. Size

Regular

use

Maxi-

mum

39-1A Thrust bearing (1) M 656 820 1 AN14

39-1B Thrust bearing (1) F

Speed increaser driven gear

408 510 2 AN12

39-2 Thrust bearing (2) 206 258 2 AN09

69 Unloader piston 80 — 1 AN05

71 Unloader slide valve 49 61 1 AN06

160 Intermediate gear coupling, drive hub 90 113 1 AN08

193 Thrust bearing, speed increaser gear 522 653 1 AN13

269 Speed increaser drive gear 1186 1483 1 AN17

Note: When tightening a lock nut, if it is difficult to use a torque wrench, manage the tightening torque

of the lock nut controlling the tightening angle range as explained below.

Tightening Angle Range of Lock Nuts for Rotors

a) After tightening the lock nut by hand, further tighten the lock nut by using a lock nut wrench until the

rotor starts to turn. Take care not to over-tighten.

b) Put a mark on the lock nut at the right side edge of the rotor groove where the stopper tongue of the

lock washer fits in, as shown in Figure 7-9.

c) From this marking position, tighten the lock nut in such a way that rotation can be stopped within the

tightening angle range shown in Table 7-3 (2016**C【39-1】,【39-2】and【160】: 30° to 40°(first time

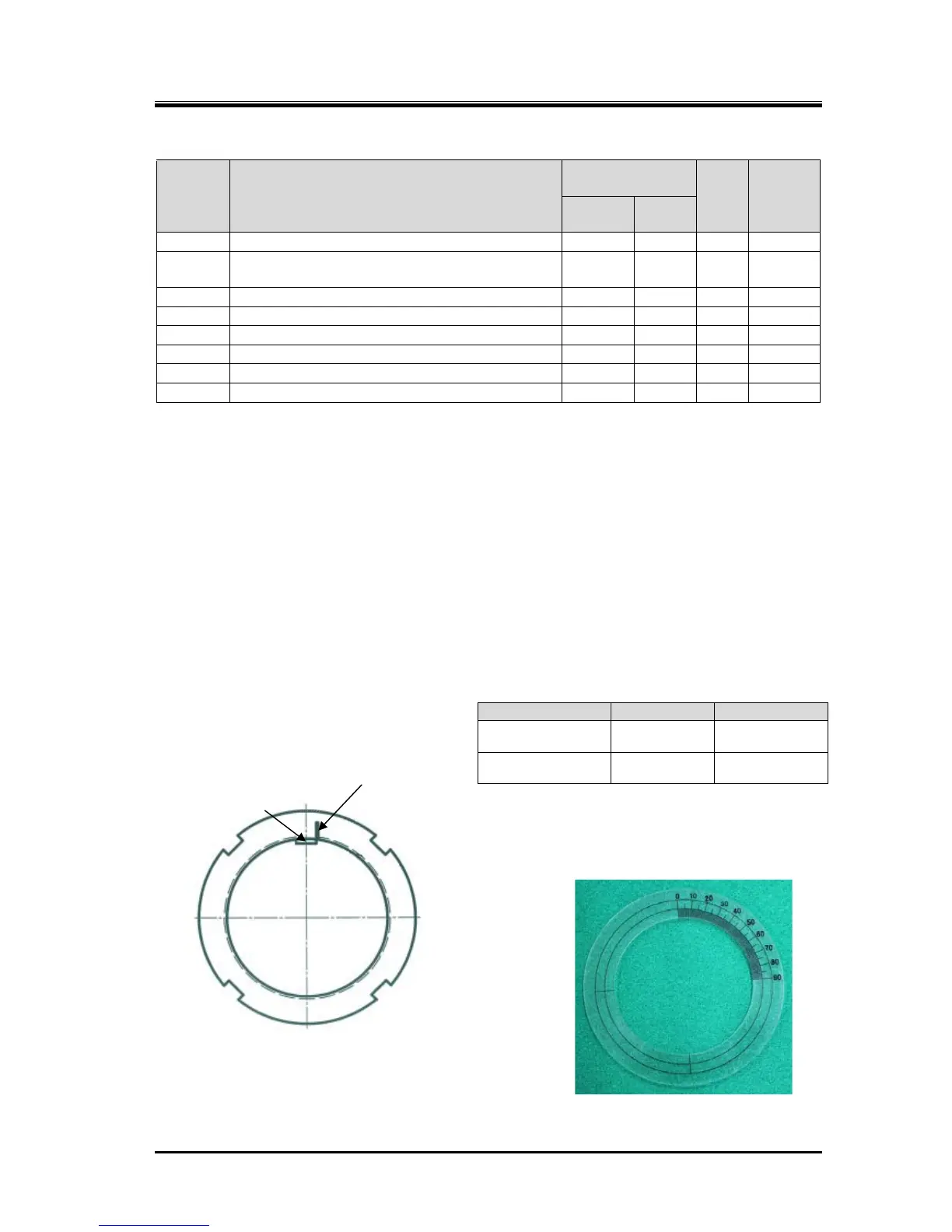

tightening), 20° to 30°(second time tightening). When measuring the angle, use an angle gauge

which is set to the diameter of rotor shaft.

Table 7-3 Tightening Angles Specified

for Lock Nuts of Rotor

* When tightening lock nut, tightening start position

differs between the first time tightening and the

tightening for the second time or after. Therefore,

angle ranges are specified also for the second

time tightening.

Figure 7-11 Position where mark is put

Angle Gauge (example)

Model Angle range

First time

tightening

125 to 250 30° to 40°

Second time

tightening

125 to 250 20° to 30°

Marking

Rotor groove (slot)

where stopper tongue of

the lock washer fits

Loading...

Loading...