2202L5JE-DA-C5-N_2015.05.

5 Maintenance and Inspection

Compound 2-stage Screw Compressor 5.5 Reassembly

1612LSC Speed Increaser Type

5-42

5.5 Reassembly

When reassembling, ensure that the replaced O-rings are of the correct standard

(size, material, for secure/moving parts etc.). Incorrect replacement can lead to

defects such as oil leakage.

Some gaskets are asymmetrical. In that case, ensure that the assembly direction is

correct. If the assembly direction is not correct, a major defect could be caused

by the oil route inside the casing being blocked.

After completing the disassembly and inspection procedures, start the assembly process.

First, read again Section 5.1 "Precautions for Maintenance and Inspection" in this Chapter 5.

Before starting the assembly, check the replacement parts once again.

Like gaskets, all O-rings that have been removed during the compressor disassembly must be replaced

with new ones.

The reassembly sequence is mostly the reverse of the disassembly sequence. First of all, clean the

work bench and the tools to be used.

Immediately prior to the assembly, use washing agent (e.g., kerosene, parts cleaner) to clean the parts

to be assembled, dry them with compressed air, and sufficiently apply lubricating oil, etc. For this,

prepare a sufficient amount of clean lubricating oil for the reassembly. Also, apply oil on both sides of

the gasket.

Because the assembly procedure is mostly similar between the high-stage and low-stage sides, the

following sections provide explanations that are commonly used for both stages. For this purpose, the

part number given in the common explanations will omit the distinction between high-stage and

low-stage by means of a hyphenated suffix (the suffix of [**-1] for low-stage and [**-2] for high-stage

part number will be omitted).

Please fully understand the details in this Section 5.5 for correct assembly work.

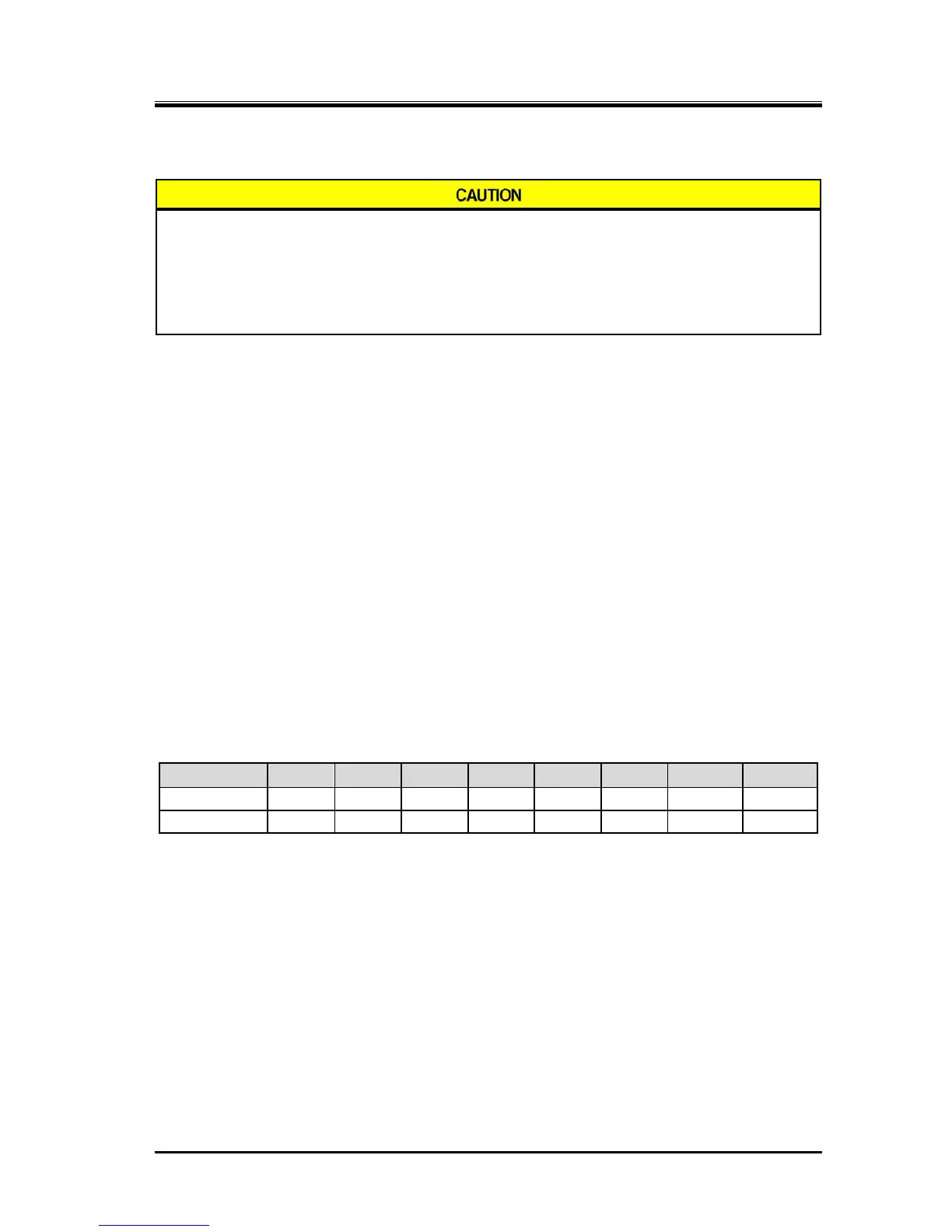

Table 5-8 Standard Tightening Torque for Hexagon Socket Head Cap Screws

Torque Unit M6 M8 M10 M12 M14 M16 M20 M24

N·m 10 25 50 90 140 240 450 750

kgf·cm 100 250 500 900 1400 2400 4500 7500

Tighten each hexagon socket head cap screw referring to the torque shown in the table above.

Loading...

Loading...