2202L5JE-DA-C5-N_2015.05.

5 Maintenance and Inspection

Compound 2-stage Screw Compressor 5.5 Reassembly

1612LSC Speed Increaser Type

5-46

5.5.3 Bearing Head and Main Bearings

a)

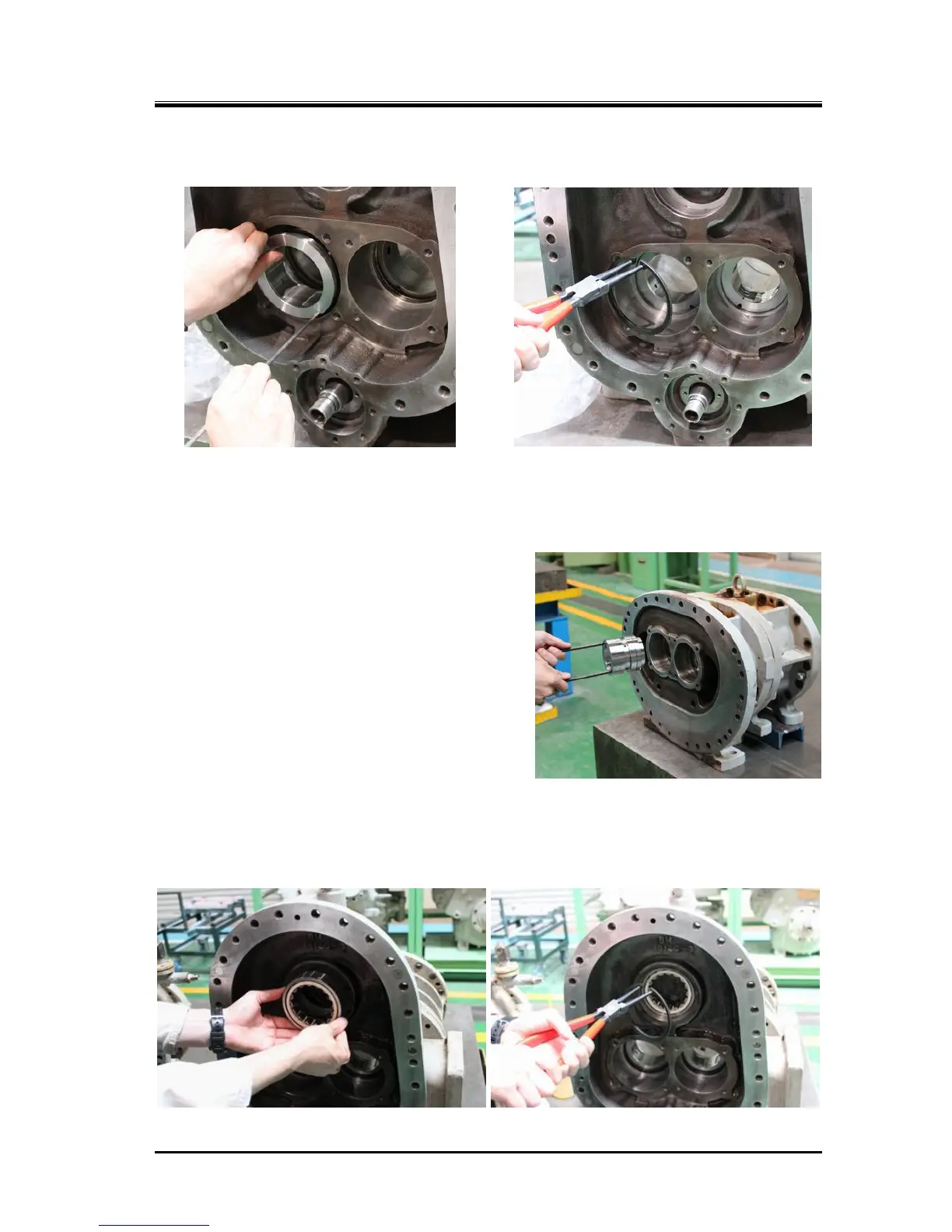

The main bearing [27] is dimensioned in such a way that it is lightly press fit to the bearing head [11].

Position the notch of the main bearing so that it is aligned with the spring pin [14] in the bearing

head (in the case of low-stage work, using a fixture such as a guide rod is helpful as shown in the

above picture to the left), then, using a pad, lightly tap in the notch.

High-stage main bearings are pushed into bearing

head using M8 eyebolts as shown in the right picture.

If the position is not aligned, pull out the main bearing

and install it in again.

b)

After attaching main bearings, secure them by

attaching internal snap rings (above picture to the

right).

c)

Low-stage bearing head [11-1] has two lubrication

holes for the speed increaser gear and the speed

increaser gear spindle. These lubrication holes are

screwed in the oil flow control throttles [196-2],

Make sure to check that there are not clogged in

the lubrication holes and throttles.

d)

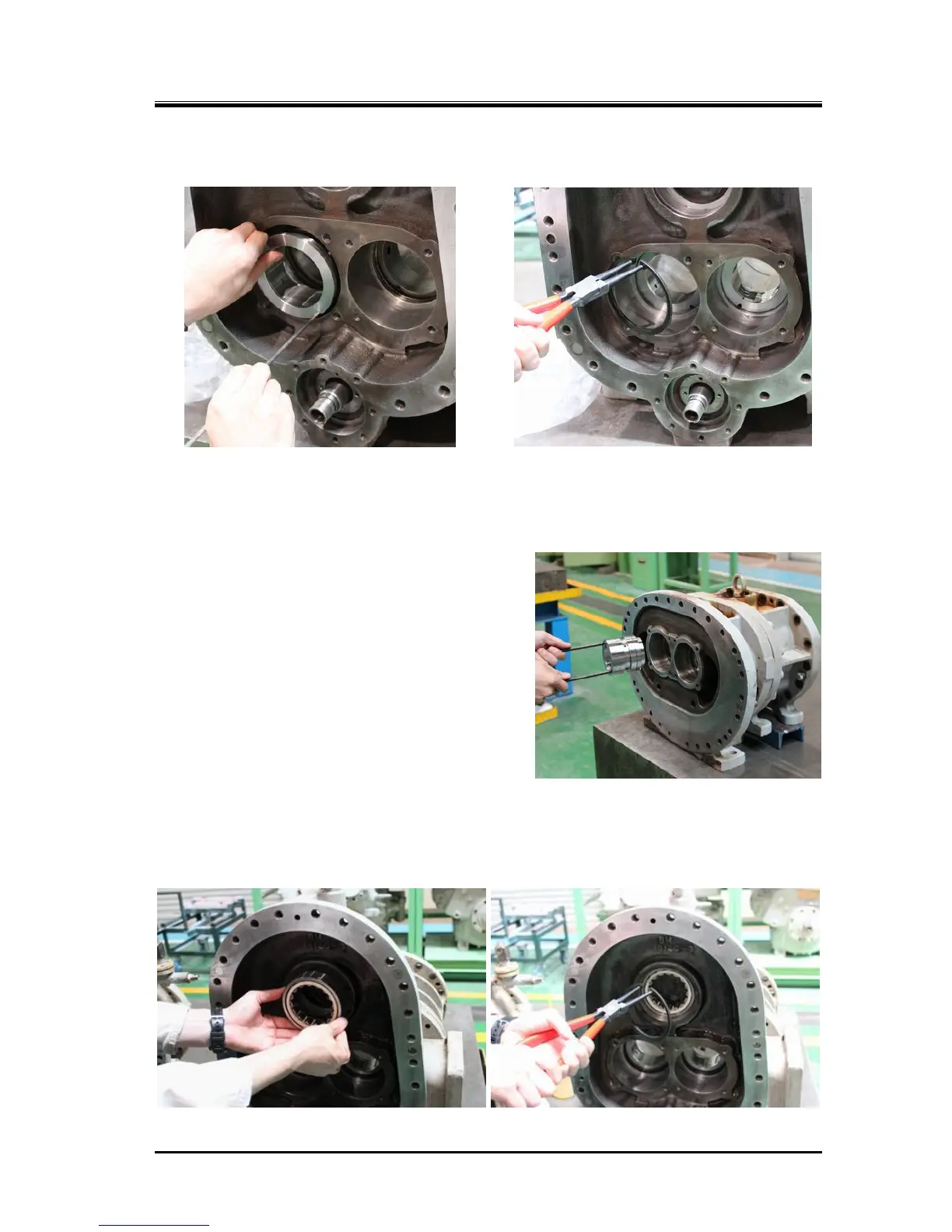

Install the outer race of the roller bearing [185] for the speed increaser gear spindle [188] into the

low-stage bearing head (following picture to the left) by securing with the internal snap ring [186]

(following picture to the right).

* : This assembly work may be performed as part of the reassembling procedure of the speed

increaser gear casing.

Loading...

Loading...