2202L5JE-DA-C5-N_2015.05.

3 Installation

Compound 2stage Screw Compressor 3.2 Installation Works

1612LSC Speed Increaser Type

3-3

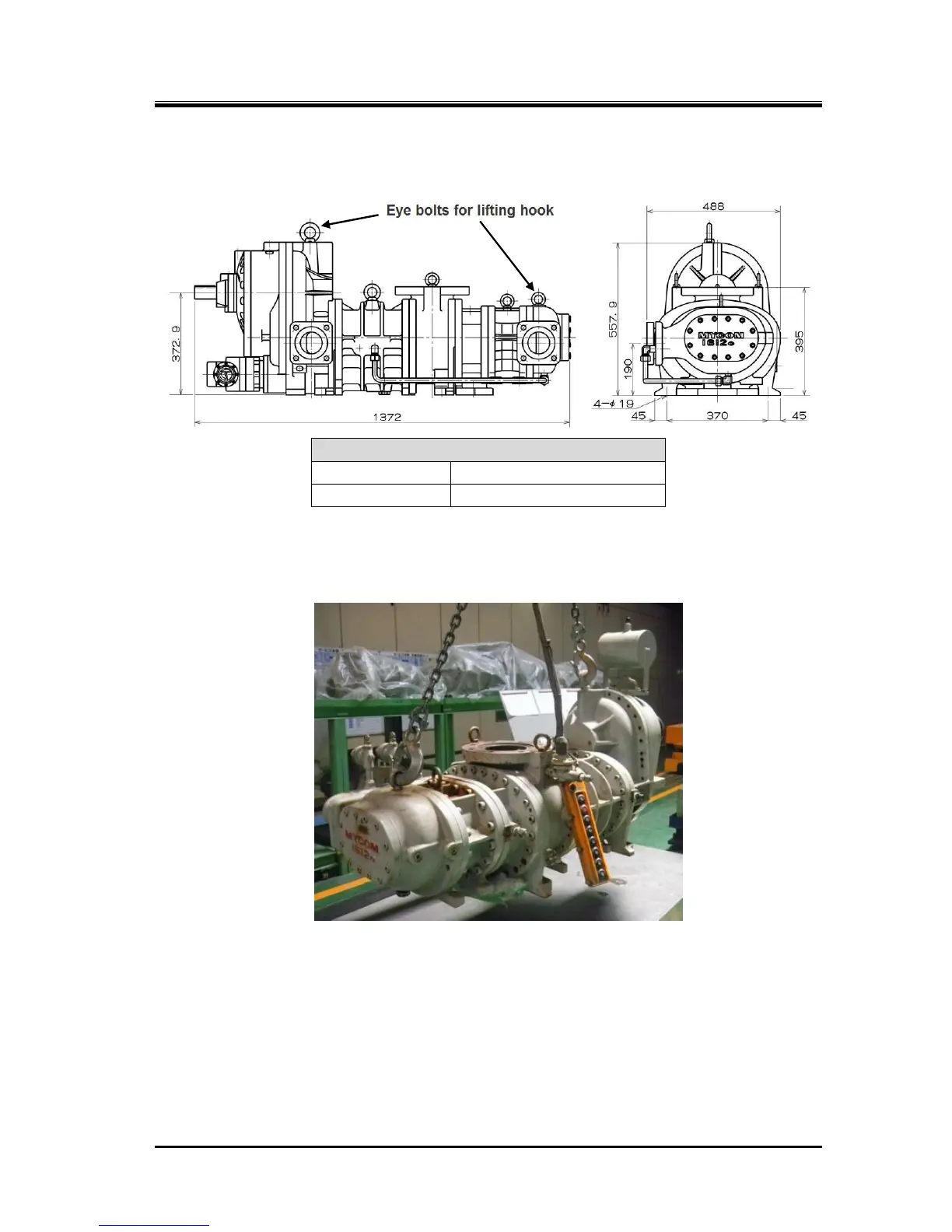

Outer Dimensions, Mass and Lifting Position

1612LSC speed increaser type common

Mass (kg) 560

Length (mm) 1372

Figure 3-1 Outer Dimensions, Mass and Lifting Position of Compressor

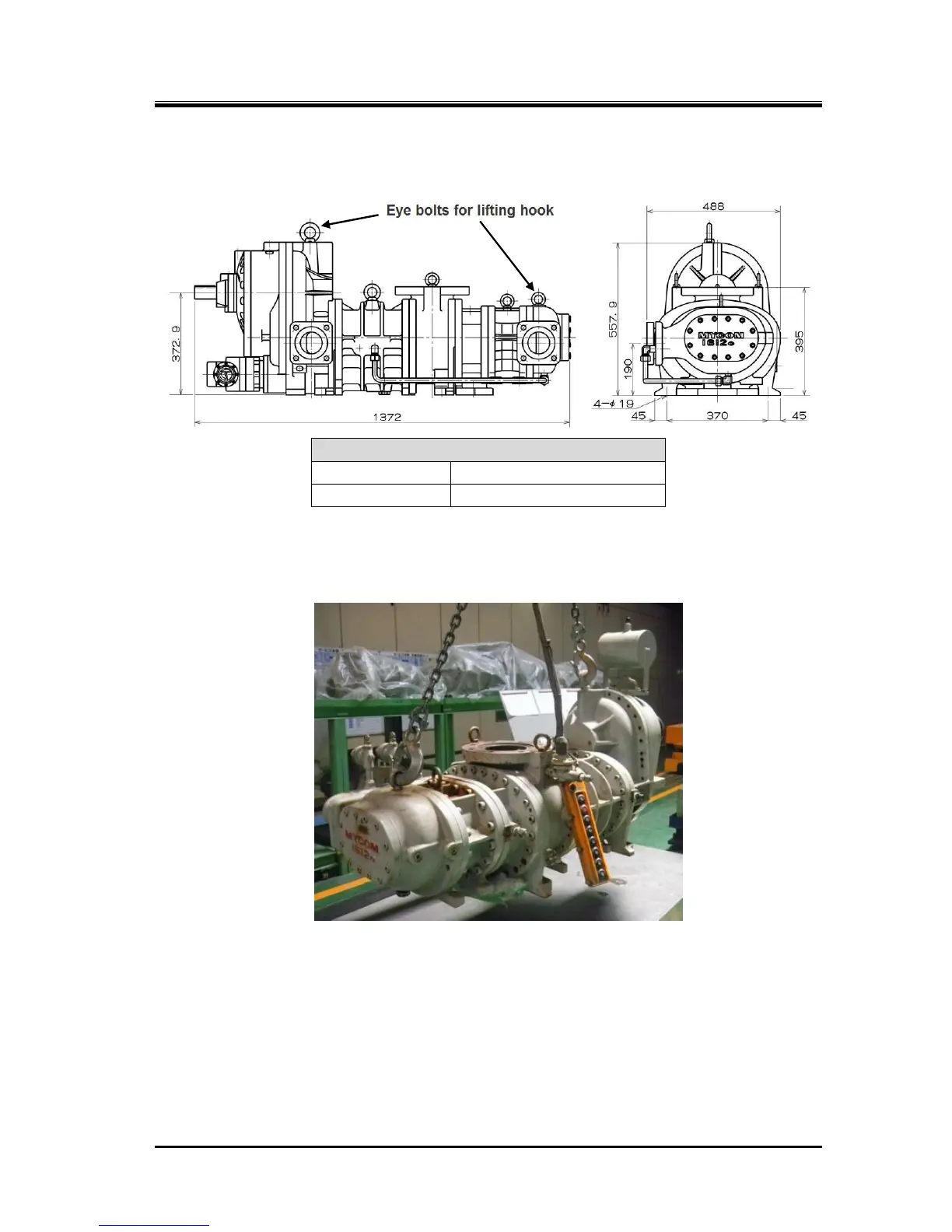

Lifted View

Loading...

Loading...