Parameter Default Description 1 2 3 4 5

Control ramp

t = XX [s]

40 Time in which the device decreases the motor power frequen-

cy from the minimum control frequency (Frequency min con-

trol) to the minimum motor frequency (Min motor frequency).

If during this time the measured value falls below Set value -

Delta control, the device restarts the motor. If not, the device

will stop the motor completely following the control ramp (Con-

trol ramp).

x x

Delta start

p = XXX.X [bar]

0.5 This parameter communicates by how much the measured

value must fall from the set value for the previously stopped

pump to be restarted.

x x

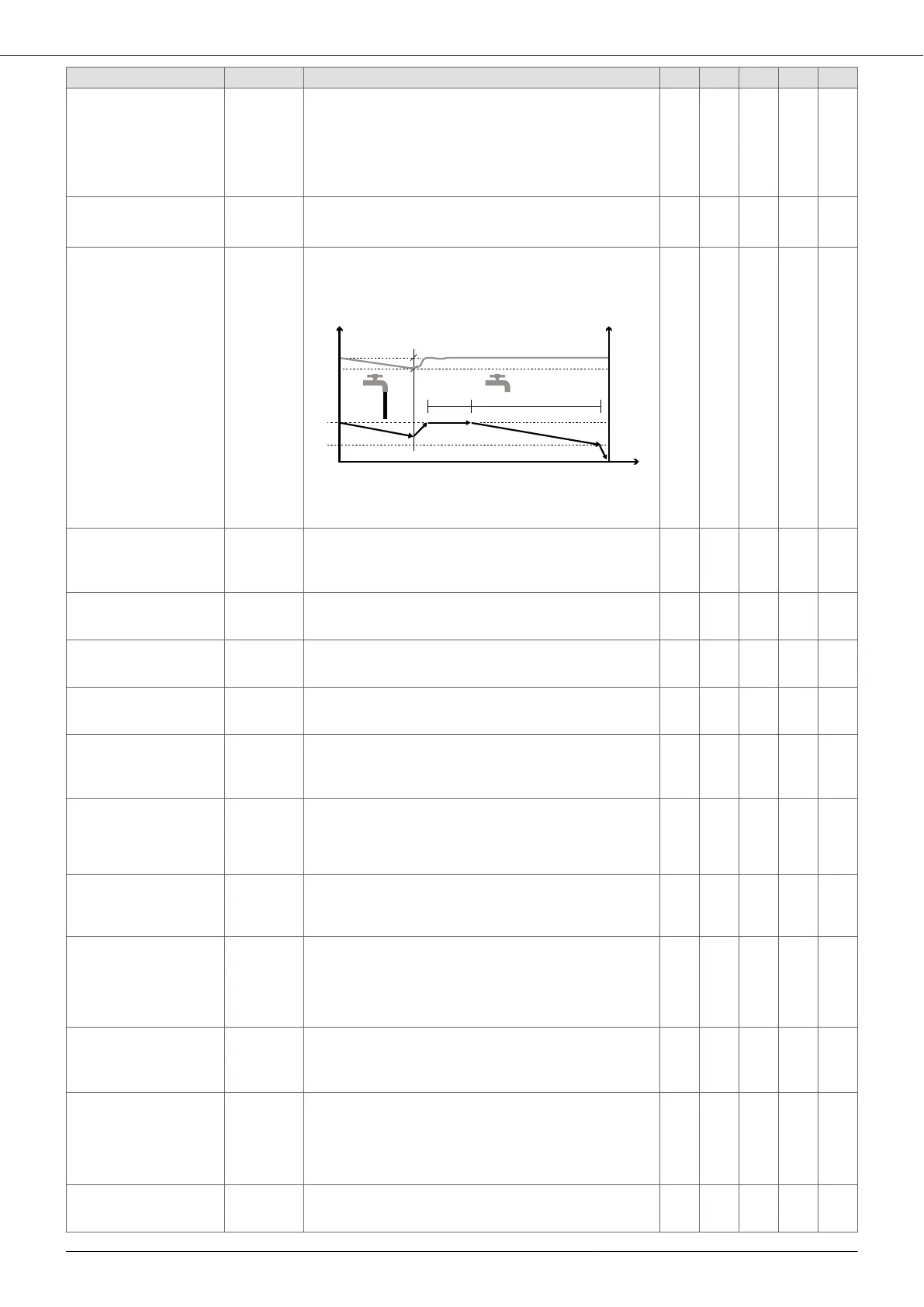

Delta control

p = XXX.X [bar]

0.1 This parameter communicates by how much the measured

value must fall in relation to the set value so that the pump,

during shutdown in control ramp, is restarted.

1: Min motor frequency; 2: Frequency min control; 3: Delta

control; 4: Set value ; 5: Stop delay; 6: Control ramp

x x

Delta stop

p = XX.X [bar]

0.5 This parameter represents the increment of the measured val-

ue with respect to the set value that must be exceeded so that

a forced shutdown of the pump according to the stop ramp can

occur.

x x

Ki

XXX

Integral coefficient used in constant value adjustment. x x

Kp

XXX

Proportional coefficient used in constant value adjustment. x x

COMBO

ON/OFF

OFF Enable the function COMBO for the combined operation of

several pumps in parallel. Read the dedicated chapter.

x x

Address

XX

01 Device address when in COMBO mode:

• 0: master

• 01 to 07: slave

x x

Alternance

ON/OFF

ON Enabling the alternation between units in COMBO and D.O.L.

The order of priority of operation is alternated based on the

previous start-up of each pump in order to obtain an almost

uniform wear of the pumps.

x x

Alternance period

t = XX [h]

0 Maximum difference in operating hours between multiple devi-

ces in the unit.

0 means 5 minutes.

x x

COMBO synchrony

ON/OFF

OFF Through this parameter it is possible to activate the synchro-

nous operation of the pumps in COMBO. Read the dedicated

chapter.

However, it is necessary to lower parameter Frequency min

controlaccordingly.

x x

Start delay AUX

t = XX [s]

00 Time delay with which the pumps in a group start up after

the variable speed pump has reached the maximum motor

frequency and the measured value has fallen below the differ-

ence Set value - Delta control.

x x

PI control

Direct/Reverse

Direct PI control mode:

• Direct: as the pump speed increases, the measured value

increases.

• Reverse: as the pump speed increases, the measured value

decreases.

x x

Periodic autorun

t = XX [h]

00 Periodic pump start-up after X hours of inactivity. The value 0

disables the function.

x x x x x

MIDA

35

Loading...

Loading...