Menu Parameter Value

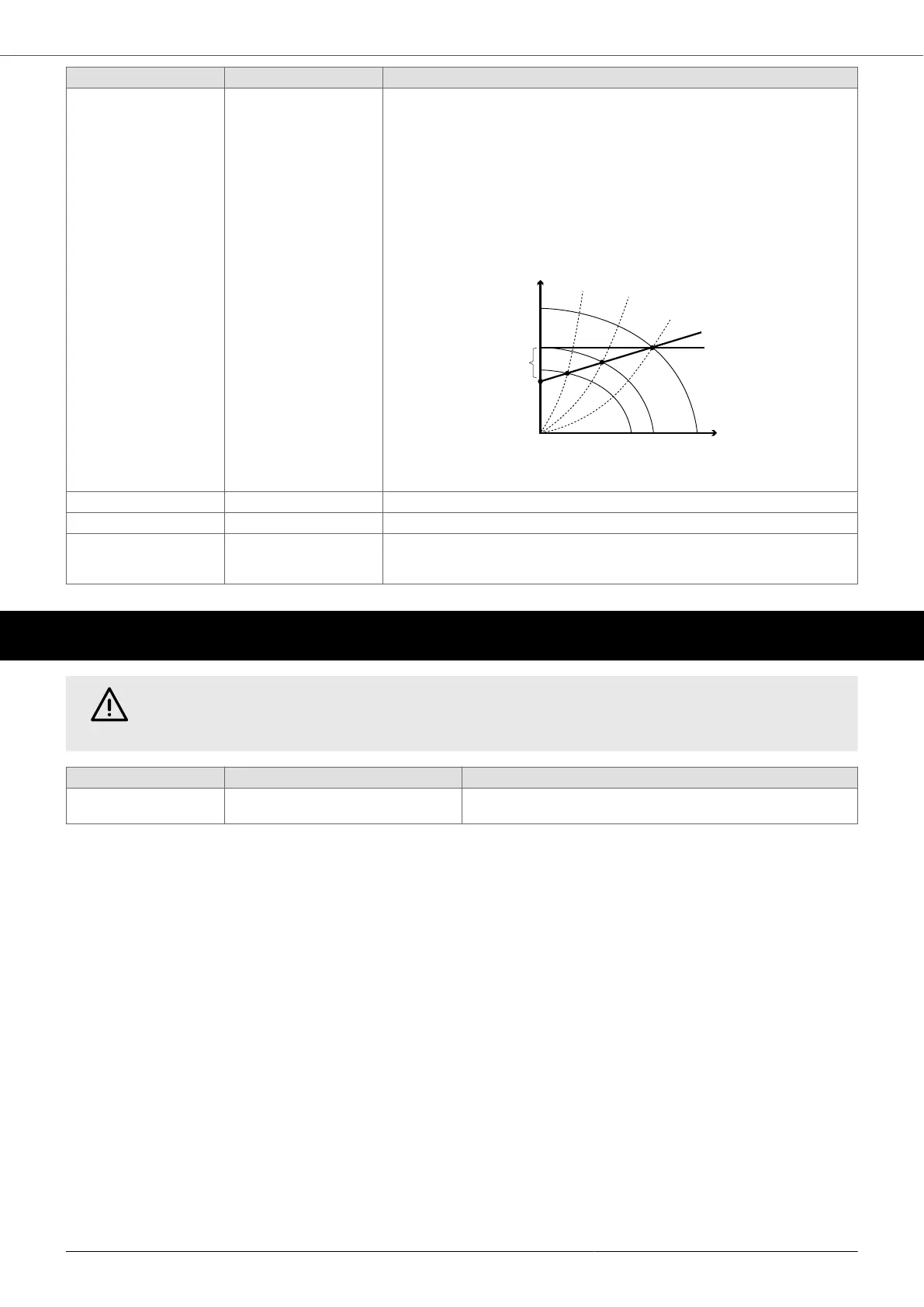

Control parameters Compensation This parameter is set other than 0 if you intend to operate a proportional differential

pressure control. Additional energy savings may be achieved through this type of

control.

The pressure difference that you want to keep constant at Max motor frequency is

given by the sum of parameters Set value + Compensation.

The pressure difference that you want to keep constant at Min motor frequency

corresponds to Set value .

The pressure set then varies proportionally between Min motor frequency and Max

motor frequency.

1: Compensation; 2: System curve; 3: Proportional differential pressure; 4: Constant

differential pressure

Control parameters Frequency min control Same as Min motor frequency

Control parameters Stop delay 99 s

Control parameters Start delay AUX In twin circulation systems (two pumps), each controlled by an inverter in COMBO

mode, this parameter should be set to 99 s in order to activate only one pump at a

time while ensuring the alternation of the same.

13. Alarms

WARNING

Immediate remedies must be implemented in case of alarms to safeguard the integrity of the device

itself and of the system in which it is installed.

Alarm Description Possible solutions

LINE<->MOT INV. Reverse the connection of the power

cable and motor cable.

• Correct the connection of the power and motor cables.

MIDA

44

Loading...

Loading...