19

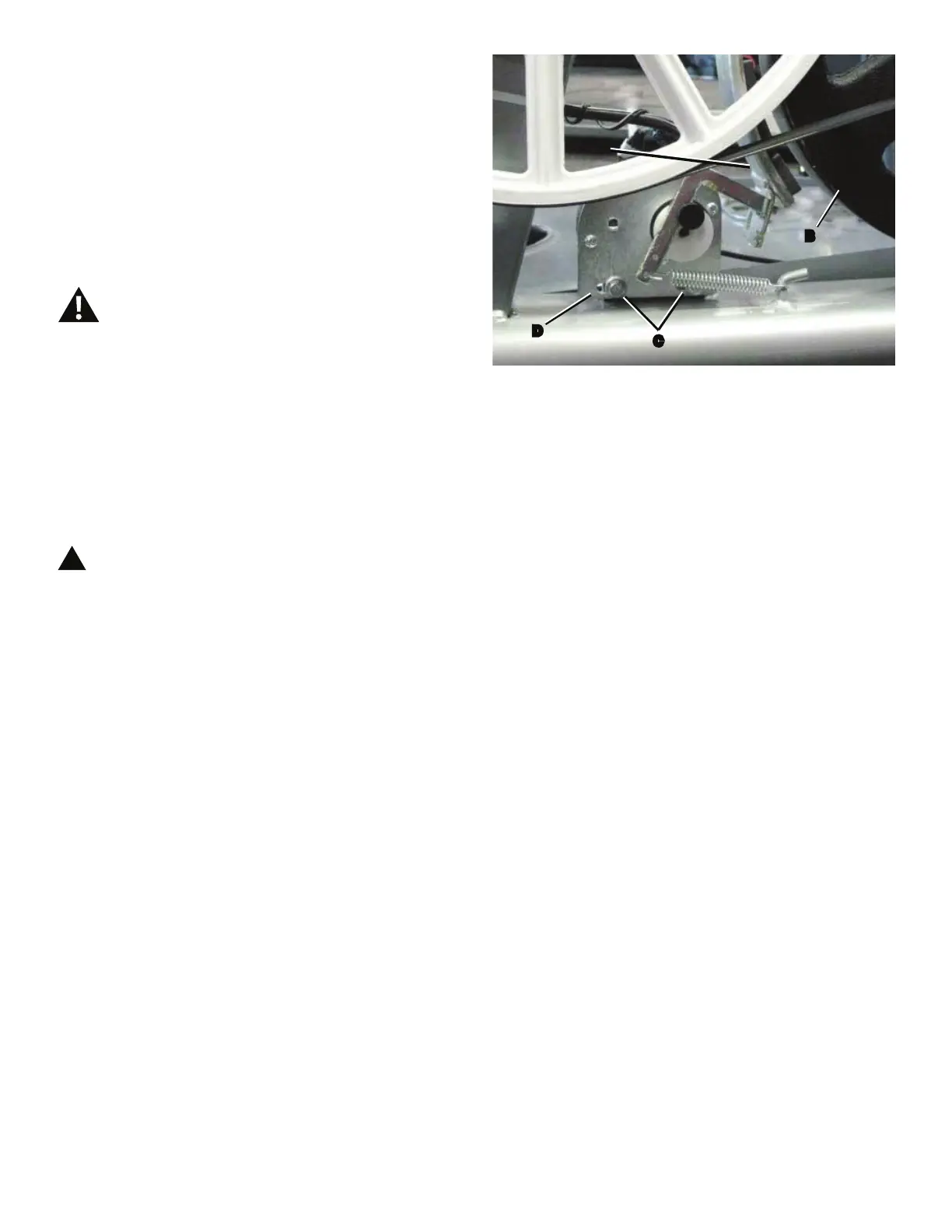

7RDGMXVWWKH%UDNHWHQVLRQORRVHQWKHKH[KHDGEROWV

(C) and move the Servo Motor assembly (D) until the closest

point on the Brake Magnet (A) is within 3.0 mm (1/8”) of the

Flywheel (B). Tighten the bolts.

Note: If the cardboard is not 3mm (1/8”) thick, you can

use the pages of a paperback book to measure

WKHJDS$SSUR[LPDWHO\SDJHVVKHHWV PP

7. Turn the power on again. Use the console to check the

resistance adjustment.

0DFKLQHLVRQ&XUUHQWLVDFWLYH7KHUHLVULVNRI

HOHFWULFDOVKRFN

Note: Before fully attaching the Shrouds, remove the

cardboard from between the Brake Magnet (A) and

the Flywheel (B). Power up the machine to verify

that the Magnet Arm can move freely, and that the

Brake Magnet and Flywheel do not touch.

8. Final Inspection

Inspect your machine to ensure that all hardware is tight and

components are properly assembled.

!

Do not use until the machine has been fully

assembled and inspected for correct performance

LQDFFRUGDQFHZLWKWKH2ZQHU¶V0DQXDO

A

B

D

C

Loading...

Loading...