58

7. Untie the string from the Console Cable (G).

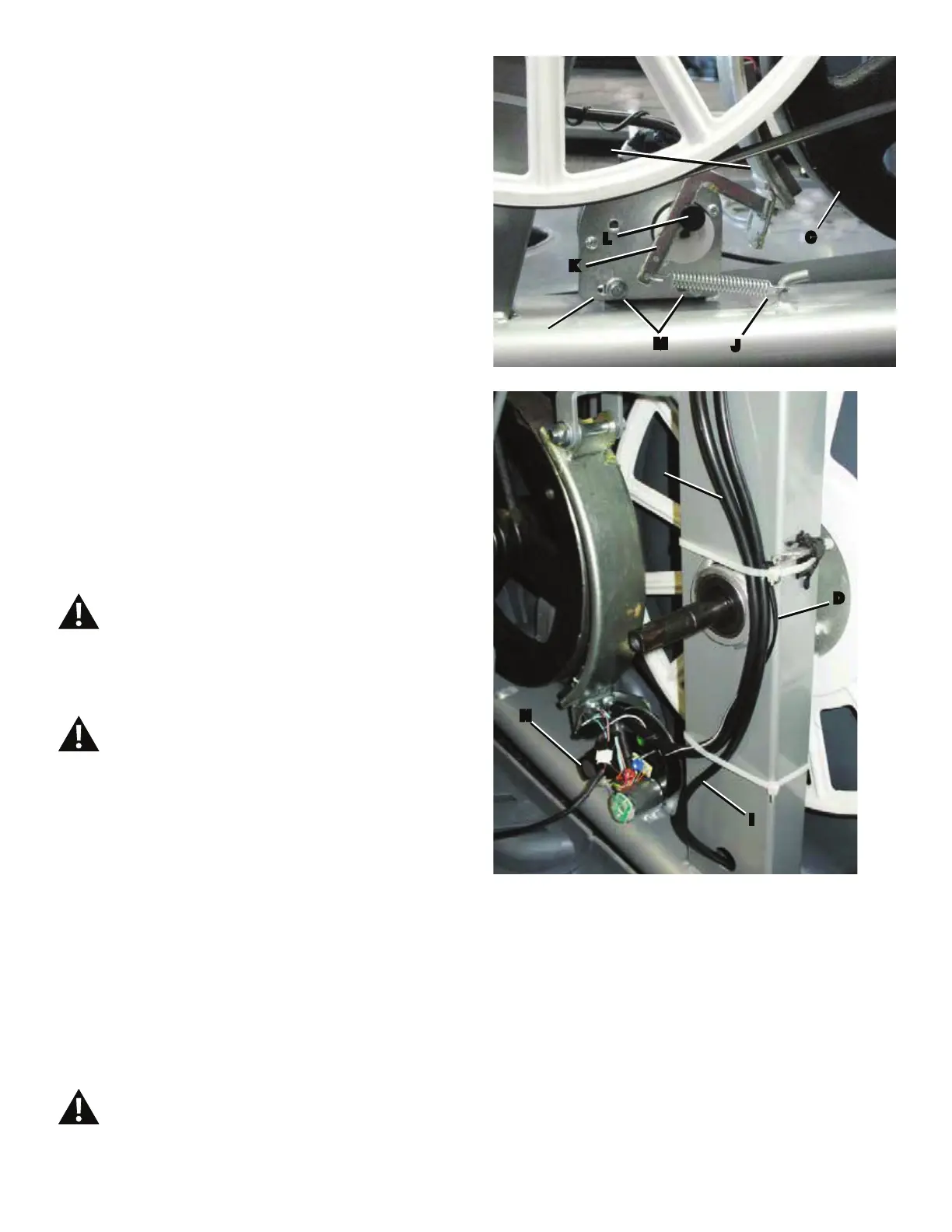

8. Use the pliers to unhook the Tension Spring (J) from

the Main Frame. Pull back and release the Magnet Arm (K)

enough to disengage it from the Motor Pulley Shaft (L).

/RRVHQDQGUHPRYHWKHWZRKH[KHDGEROWV0IURPWKH

Servo Motor (A).

10. Remove the Servo Motor (A). Discard the old Servo Motor.

11. Installation is the reverse procedure. Adjust the new

Servo Motor to same position recorded in Step 3.

NOTICE: Do not touch the Potentiometer (N). Do not

crimp any cables.

12. Tie the end of the string at the hole (H) in the Mast to

the end of the Console Cable (G) on the new Servo Motor

(A). Carefully pull the cable through the hole to the top of the

Mast mount. Untie the string and discard it.

13. Reinstall the Mast, Console and Top Shroud. (Refer to

the “Replace the Shrouds” procedure.) Turn the power on.

0DFKLQHLVRQ&XUUHQWLVDFWLYH7KHUHLVULVNRI

HOHFWULFDOVKRFN

14. Use the console to set the resistance to the highest

level. Unplug the machine.

'LVFRQQHFWDOOSRZHUDQGDOORZWRVLWIRU

minutes.

15. Put the Brake Arm (K) back in position and connect the

Tension Spring (J) with the needlenose pliers.

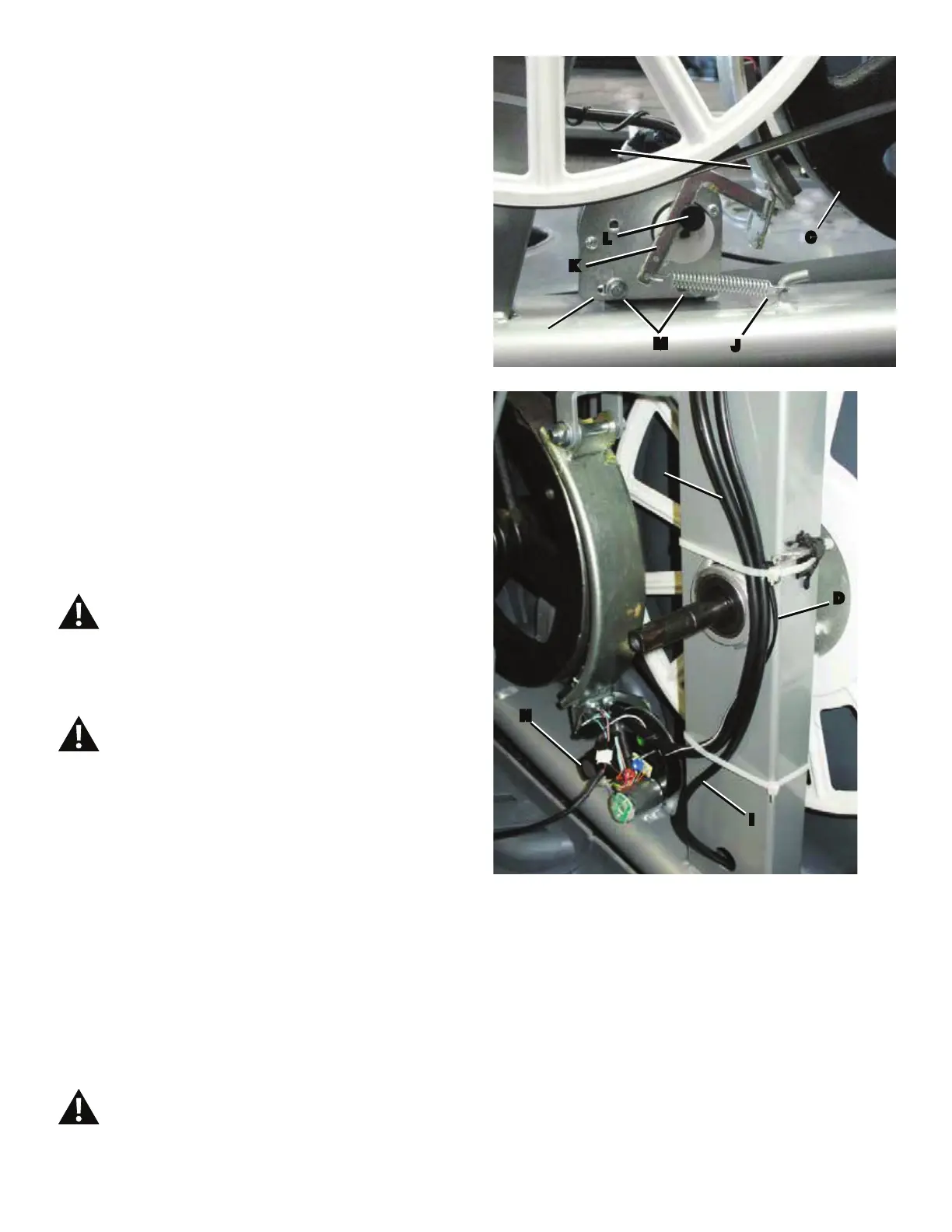

Note: Before fully attaching the Shrouds, remove the

cardboard from between the Brake Magnet (B)

and the Flywheel (C). Power up the machine to

verify that the Magnet Arm can move freely, and

that the Brake Magnet and Flywheel do not touch

DWWKHPD[LPXPUHVLVWDQFHOHYHO,IQHFHVVDU\

refer to the “Set the Brake Tension” procedure.

16. Final Inspection

Inspect your machine to ensure that all hardware is tight and

components are properly assembled.

Do not use until the machine has been fully

assembled and inspected for correct

SHUIRUPDQFHLQDFFRUGDQFHZLWKWKH2ZQHU¶V

Manual.

L

A

B

C

M

K

J

G

D

I

N

Loading...

Loading...