24

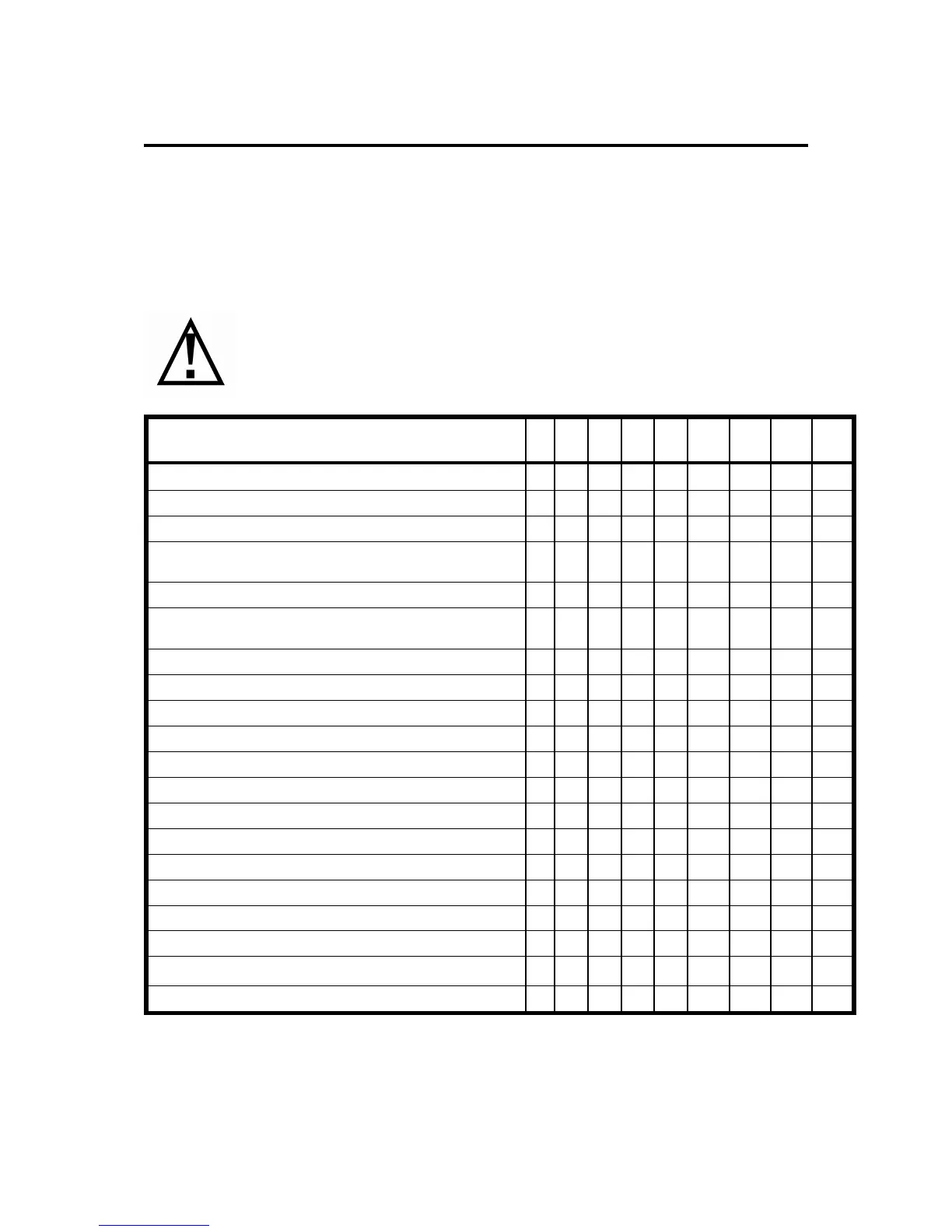

Service Schedules

CALENDAR EQUILIVANTS

10Hours = Daily

50 Hours = Weekly

100 Hours = Fortnightly

500 Hours = Six Months

1000 Hours = Yearly

2000 Hours = 2 Years

ENGINE

Service Points & Fluid Levels

Operation 10

Hr

50

Hr

200

Hr

500

Hr

800

Hr

1000

Hr

1500

Hr

2000

Hr

3000

Hr

Oil level

(1)

Check

●

Coolant Quality / Level Check

●

Coolant or Oil Leaks Check

●

Fuel Filter & Water Sedimentor

(2)

Check for contamination

& Drain

●

Air Filter Check evacuator & empty

●

Fan Belt Check if necessary,

re-tighten or renew

●

Oil & Filter

(3) (4)

Change

●

●

All Hoses & Electrical Cables—Condition Check

●

Radiator

(5)

Clean

●

Fuel Filter Element Change

●

Fuel Tank Clean to remove sediment

●

Fan Belt Change

●

Valve Clearances

Check

●

Air Cleaner Outer Element

(5)

Change

●

Fuel injection nozzle pressure

(6)

Check

●

Air Cleaner Inner Element

(5)

Change

●

Cooling System Drain & Fill

●

Injection Pump

(6)

Check

●

High Pressure Fuel Lines Inspect

●

Fuel Injection Timer

(6)

Check

●

1

The oil level should be checked twice a day for the first 200 hours then once a day is sufficient.

2

Check & change if noticeable performance related problems due to fuel restrictions.

3

If the specified intervals between oil changes have not been reached the oil should be changed at least once a year

4

The oil service interval will be reduced if there is a high sulphur content in the fuel. Refer to fuels & lubricants section.

5

If operating in dusty adverse conditions do these jobs more frequently.

6

These jobs must be done by a qualified engineer.

Note: ● First Interval Hr Service only during engine running in period.

Service checks should be carried out at which ever interval occurs first. Do not

use a machine which is due for a service. i.e. If the dumper has completed less

than 2000 hours at the 2 year period carry out the 2000 hour service.

Make sure

any defects found during the regular maintenance are rectified immediately.

Dots are for every interval i.e. 50hr service is carried out every 50 hours etc.

Loading...

Loading...