© 2016 Nelson Stud Welding, Inc. Page 18

All Rights Reserved. February 2016 Part No. 729-110-042 v1.03

6 Troubleshooting

6.1 Visual Weld Inspection and Weld Parameter Adjustments

Situation:

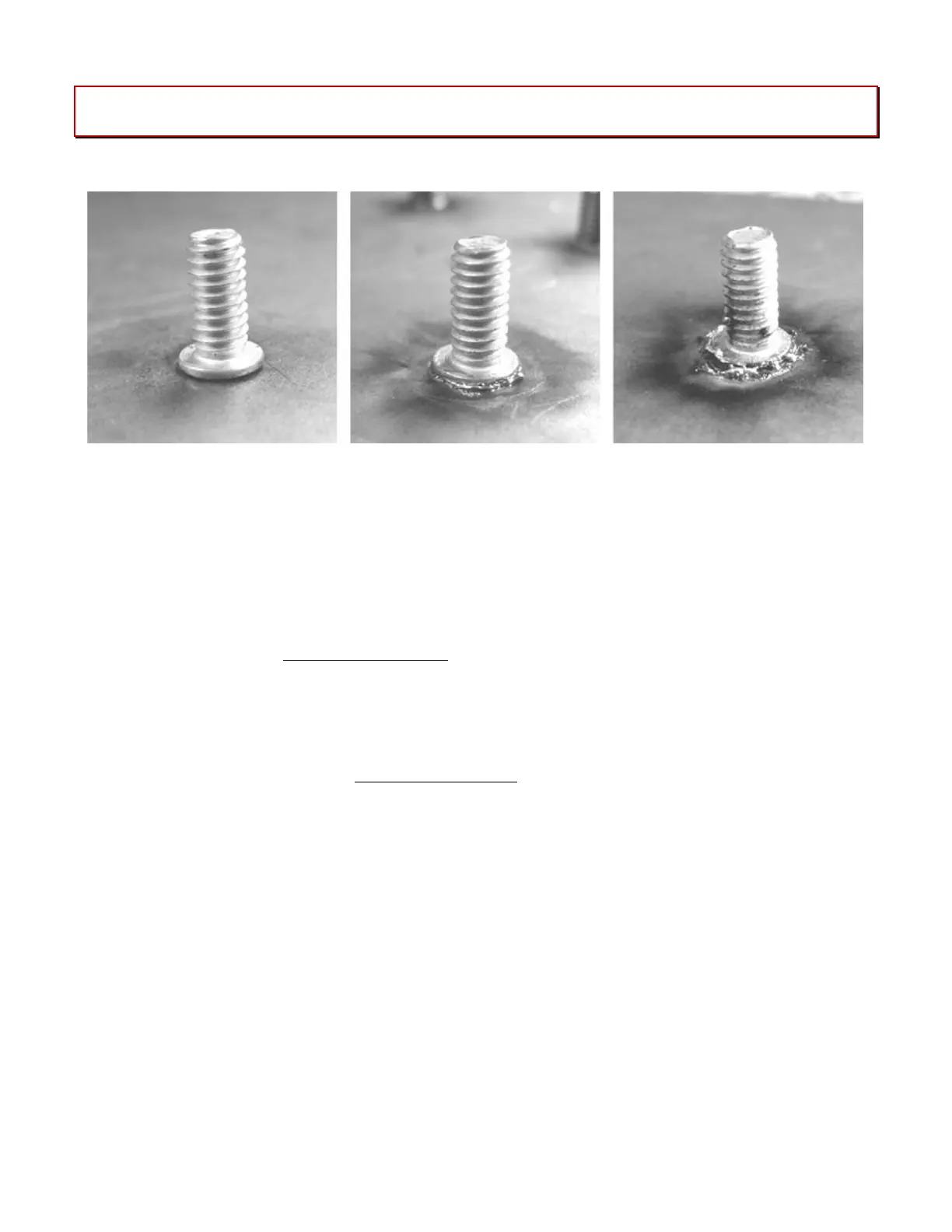

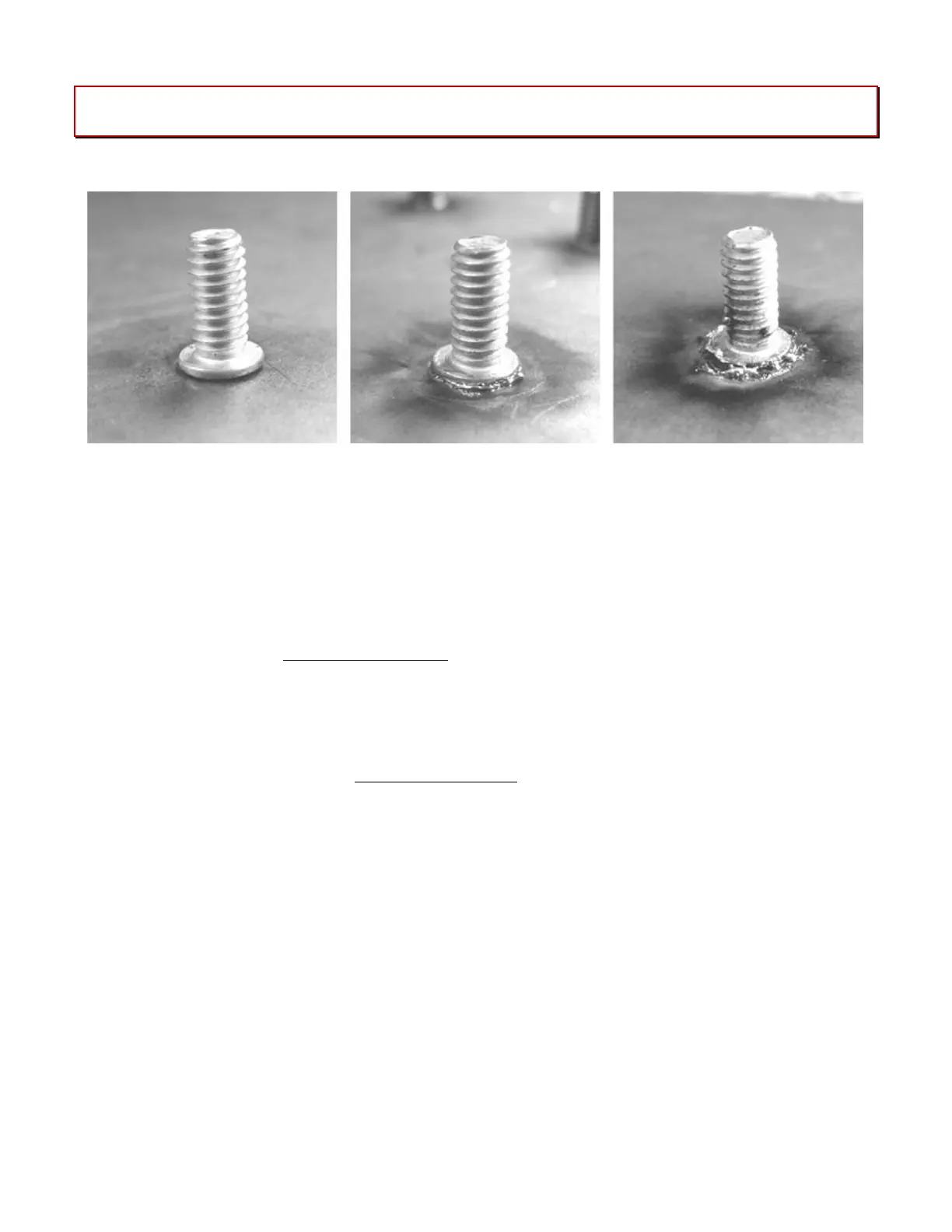

Acceptable Weld

Figure 6.1 Weld Quality Visual Inspection

6.2 Weld Quality Physical Inspection and Weld Parameter Adjustments

If visually inspecting the welds reveals a questionable weld, the weld should be physically tested. Initial weld set

ups should also be physically tested.

Suggested physical tests for steel and stainless steel studs are as follows:

4 Bend Test. Stud to be tested shall be bent away from its vertical axis 90° or until failure. Failure should occur

in the stud shank, or, on thin plate, a full stud diameter plug of base metal should be torn out.

5 Torque Test. Stud shall be torqued until a pre- specified loading is attained or until the stud fails. On thin

plate, a plug of the base material should tear out.

Physical test procedures for inspecting (magnesium) aluminum alloy studs are:

1. Bend Test. The stud to be tested shall be bent, using a bending tool approximately 15° away from its vertical

axis before the stud breaks in the shank or the base material fails.

2. Torque Test. The stud to be tested shall be torqued in the conventional manner by applying torque until a

predetermined torque load is reached or the stud fails.

6.2.1 Recommendations

Before starting any stud welding operation, or after the equipment has remained idle for a period of time, trial or

test studs should be welded to a plate for testing. Testing should continue until there is no failure of a test stud.

NOTE: Do not bend aluminum studs by striking with a hammer, always use a bending tool. The stud weld should not

be damaged, only the stud shank or the base material.

Loading...

Loading...