Lubrication and Service

The RainTrain2

®

requires very little maintenance. Inspect the RainTrain2

®

before each irrigation season and each

irrigation run. Please follow these service recommendations to assure a long and productive life for your RainTrain2

®

.

Before each Irrigation Season

1. When taking the RainTrain2

®

. out of storage, be sure there are no rodent or

insect nests that may plug filters, valves, or sprinklers.

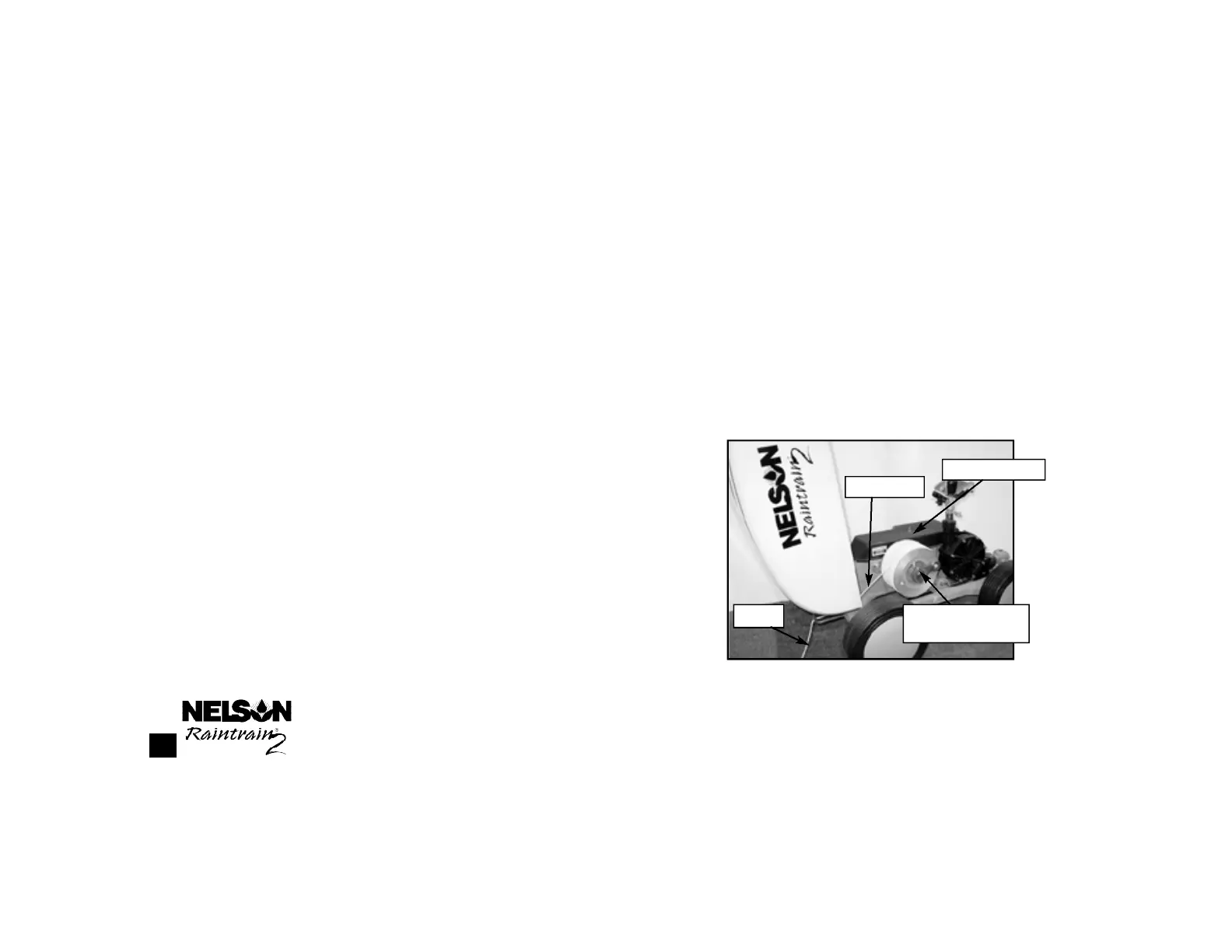

2. Carefully remove the gearbox cover (see Disassembly and Assembly) and

inspect the gears for any missing teeth or abnormal wear (see figure 8).

Your RainTrain2

®

gearbox does not require any further lubrication.

Verify that the three drain holes in the bottom of the gearbox are

not plugged. Make sure that there is no debris in your RainTrain2

®

gearbox. Replace the cover.

3. Pull the cable completely out of the unit and inspect for worn or frayed strands

(see figure 8). If any strand is broken, the cable should be replaced.

4. Inspect the cable drum disengage mechanism. Repair or replace if necessary.

5. Inspect the cable guide pulley at the front of the unit (see figure 8). This pulley

does not require lubrication. The pulley should rotate freely. If the pulley

does not rotate freely, disassemble, clean, and replace

(See Disassembly and Assembly).

12

Figure 8. Left hand view of machine

with cover open.

Cable Guide

Gearbox Cover

Cable Drum

Engage/Disengage

Cable

Loading...

Loading...