N E T A F I M T E C H L I N E

®

C V D E S I G N G U I D E

N E T A F I M T E C H L I N E

®

C V D E S I G N G U I D E

BASIC

DESIGN

STEPS

(continued)

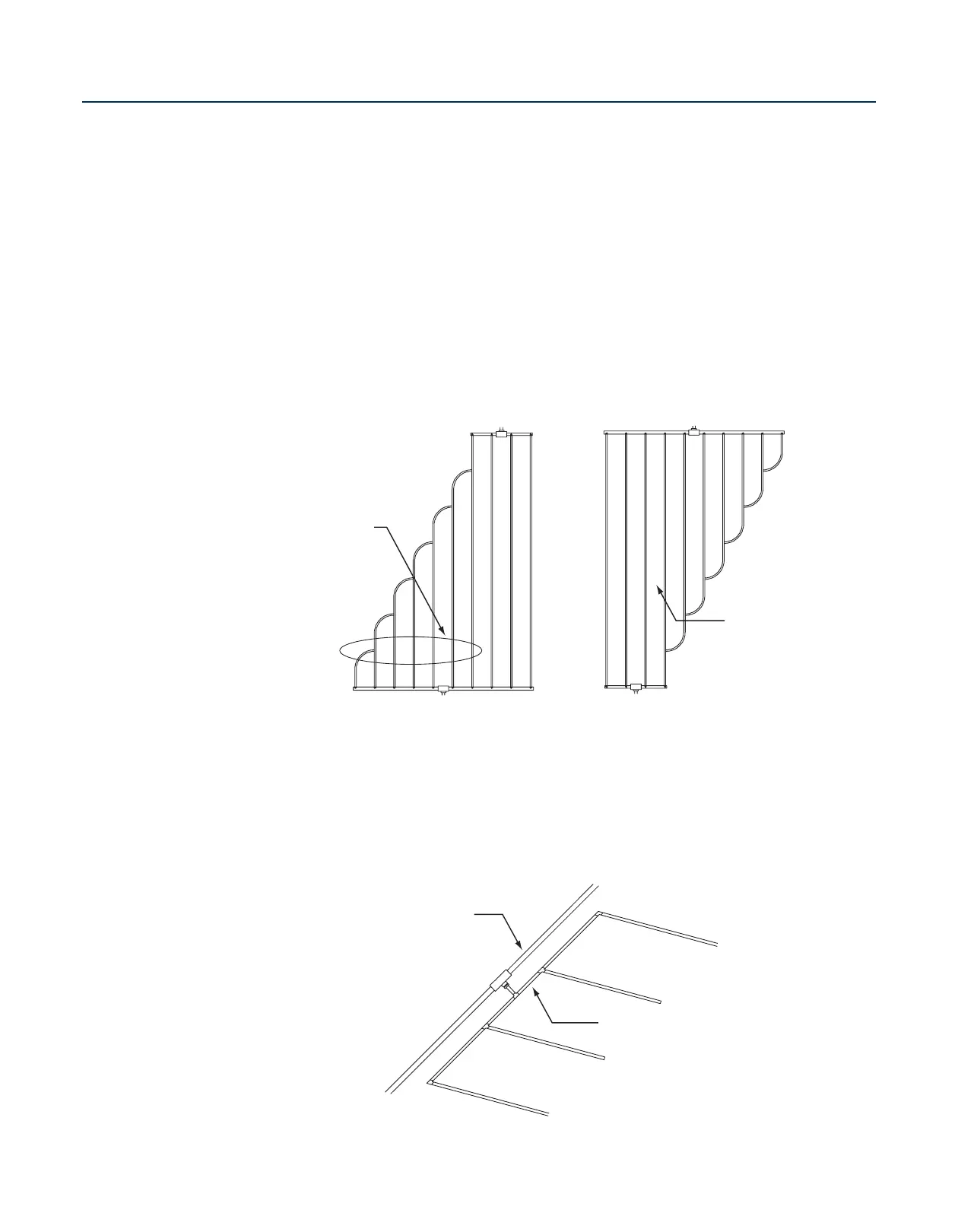

• To reduce the number of glue joints, saddles or insert fittings in a header, transition to Techline CV

and Techline fittings to make up subheaders.

• Make sure to follow the guideline of not exceeding 5 GPM in the “sub-header” zone.

OTHER GRID LAYOUT CONSIDERATIONS:

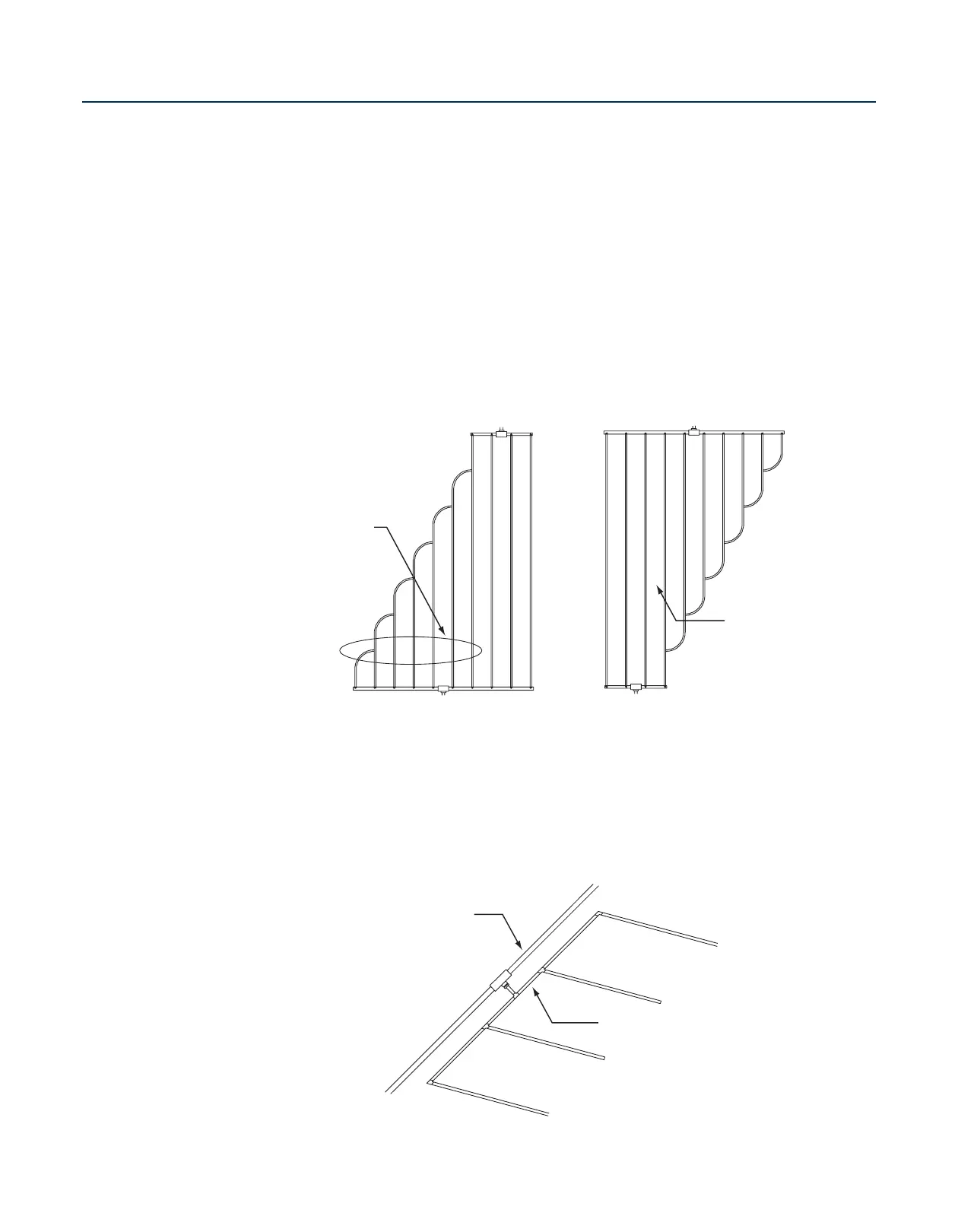

• When branching out or joining rows of Techline CV, one of two rules apply:

Rule #1: When branching out Techline CV from the supply header, add up all “branched out”

dripperline and check it against the maximum lateral length listed in Table 2.

Rule #2: When joining laterals from the supply header, check only the longest lateral against the

maximum allowable in Table 2.

Exhaust Header

Supply Header

Check longest

lateral agains

Table 2 for

maximum

lateral length.

Joining

Techline CV Laterals

Exhaust Header

Supply Heade

Total the combined

length of these

Techline CV laterals

and compare it

against the maximum

lateral length allowed

in Table 2.

Branching Out

Techline CV Laterals

Techline fittings

and dripperline

PVC or

Poly Piping

Creating Sub-Headers to

Reduce Glue/Saddle Joints

Loading...

Loading...