C70 Digital Readout System

Segmented Error Compensation

SETUP, Segmented Error Compensation

NOTES

Up to 99 segments can

be defined per axis

To take advantage of

Segmented Error

Compensation, you will

need access to a high

accuracy standard, such

as a laser measuring

system.

Error Compensation

initially defaults to off,

with no points set.

If Error Compensation is

set to Off after

Correction Points have

been set, the data is

retained, but not applied.

When Segmented Error

Compensation is set to

On again, the data will

be re-applied.

This procedure must be

carried out in strict

sequence, and in full, to

be valid. There must be

no reversals in direction.

Pressing select key

at steps 1, 2 or 3, will

display the current

uncorrected position

relative to the (Starting

Point).

Do not worry about the

direction of the standard

measurement. eg. 678.9

and -678.9 are treated

the same.

Pressing

will clear

an entry one character at

a time.

After an entry has been

completed by pressing

, pressing

will take you back one

step at a time.

Newall Measurement Systems Ltd 11

If one or more axes are set to Segmented Error Compensation, then the following procedure should

be followed to configure the compensation for each of those axes.

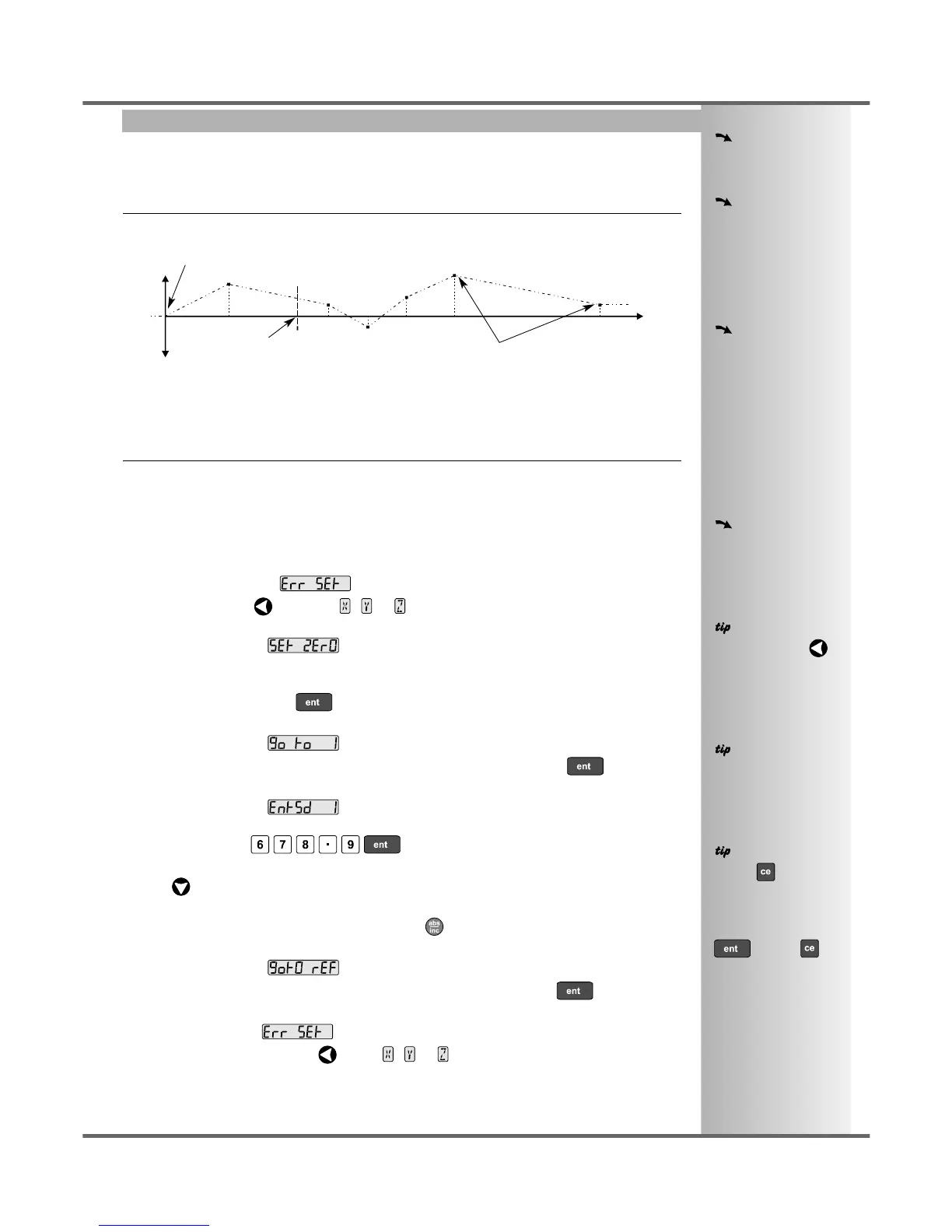

Identification of Correction Parameters

The scale travel is broken down into a number of user-defined segments, each with its own correction

factor, measured against a high-accuracy standard. The following parameters need to be identified:

error

travel

Starting Point - zero

Correction Points

Reference Point

0

1

2

3

4

5

6

Each Correction Point is measured with respect to the Starting Point - zero - which is usually set close

to one end of the scale. The Reference Point can be set anywhere along the scale, and does not need

to coincide with either the absolute datum or any of the correction points. However, it may be convenient

to make the absolute datum and the reference point the same.

Setting the Correction Points

As you follow the steps below, it is essential to take the following precaution:

Always approach the Starting Point, Correction Points and Reference Point from the same

direction. If you do not, then the size of the tool or probe will render the measurement inaccurate.

• Set one or more axes to Segmented Compensation as described on page 10.

The display should show, .

• Press the Select Key next to the , or to enter the setup procedure for each axis to be

configured.

The display changes to .

1 Set the machine to the point you have chosen to the Starting Point, and zero the high-accuracy

standard at this point. Press .

2 The display changes to .

Set the machine to the point you have chosen to be Correction Point 1. Press .

3 The display changes to .

Enter the distance from the Starting Point, as measured by the standard.

For Example: Press to enter a Correction Point of 678.9.

The C70 will calculate and display the correction factor for this point.

• Press to go to the next point.

Repeat steps 2 and 3 for each Correction Point.

When all correction points have been entered, press .

4 The display changes to .

Set the machine to the point you have chosen as the Reference Point. Press .

5 The display returns to .

If required, press the Select Key next to , or to enter the setup procedure for another

axis.

Loading...

Loading...