Linear Error Compensation

SETUP, Linear Error Compensation C70 Digital Readout System

NOTES

The Correction Factor

cannot be established

while in Setup Mode.

Carry out the

measurements in Normal

Operating Mode, then

enter Setup Mode to set

the Correction Factor.

Only values between

-9999 and 9999 are

allowed.

If you make a mistake

while entering a number,

pressing will clear

the entry one character

at a time.

Newall Measurement Systems Ltd12

A single constant correction factor for each axis is applied to all displayed measurements.

If one or more axes are set to Linear Error Compensation, then the following procedure should be

followed to configure the compensation for each of those axes.

Calculating the Correction Factor

As you follow the steps below, it is essential to take the following precaution:

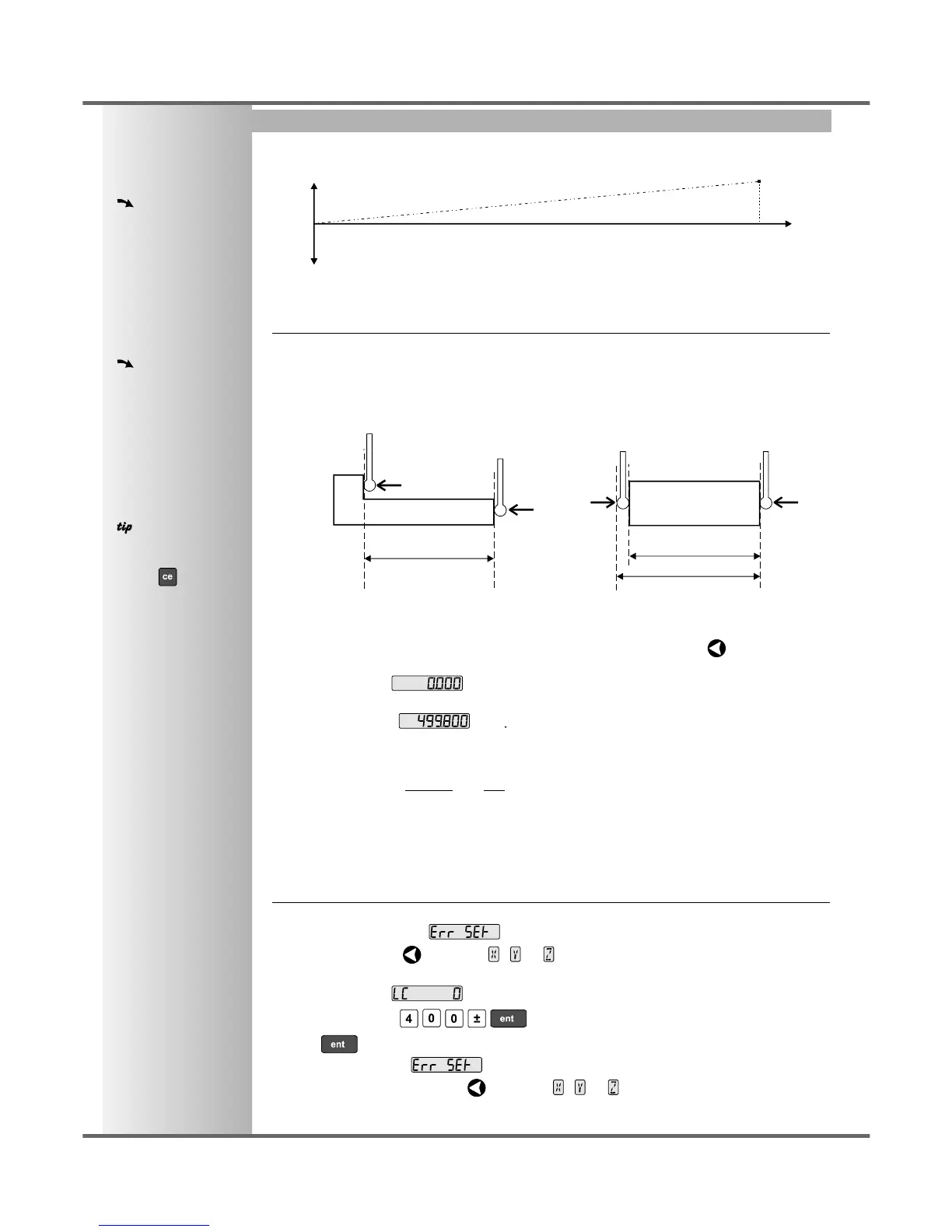

Either: Use a stepped standard, and approach each edge from the same direction.

Or: If you must approach each edge from opposite directions, then subtract the width of

the tool or measuring probe from the value displayed on the C70.

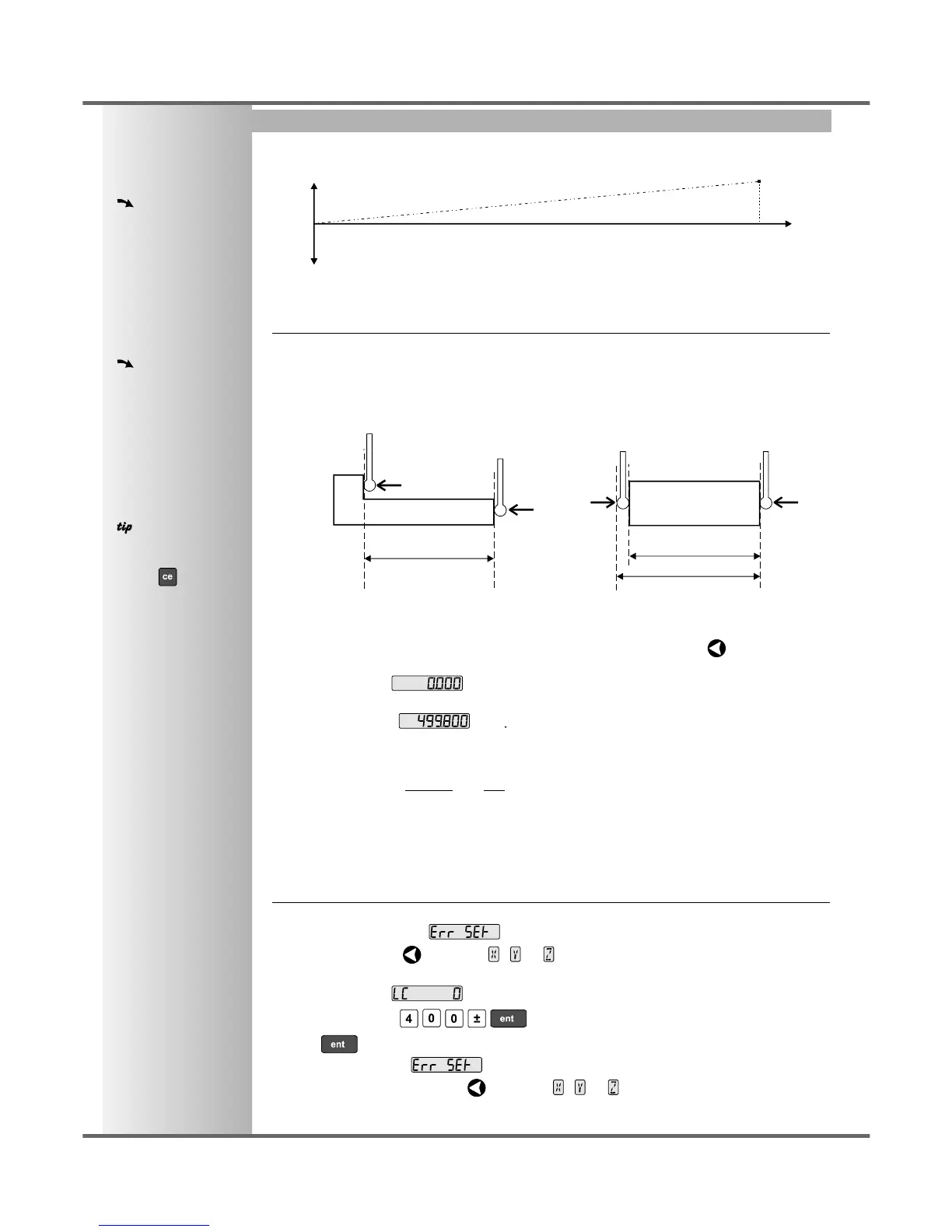

For Example: To check the scale against a standard which is exactly 500mm wide:

• Set the tool or proble to one edge of the standard, and press the Select Key for the axis to be

corrected.

The display shows .

• Set the tool or probe to the other edge of the standard.

The display shows , .

• Calculate the correction factor:

error = 500.000 - 499.8 = 0.2mm

Correction Factor = = x 1,000,000 = +400 ppm (parts per million)

This value displayed on the C80 needs to be increased to match the standard, so this is a positive

correction factor. If the display had shown 500.2 for the same standard, the correction factor

would be negative -400 ppm.

Setting the Correction Factor

• Set one or more axes to Linear Error Compensation as described on page 10

The display should show, .

• Press the Select Key next to the , or to enter the setup procedure for each axis to be

configured.

The display shows , or a previously entered value.

• For Example: Press to enter a Correction Factor of -400 ppm.

• Press again.

The display returns to .

If required, press the Select Key next to the , or to enter the setup procedure for

another axis.

0.2

500

error

standard

error

travel

standard distance

measured distance

= standard distance

tool or

probe

tool or

probe

measured distance

Loading...

Loading...