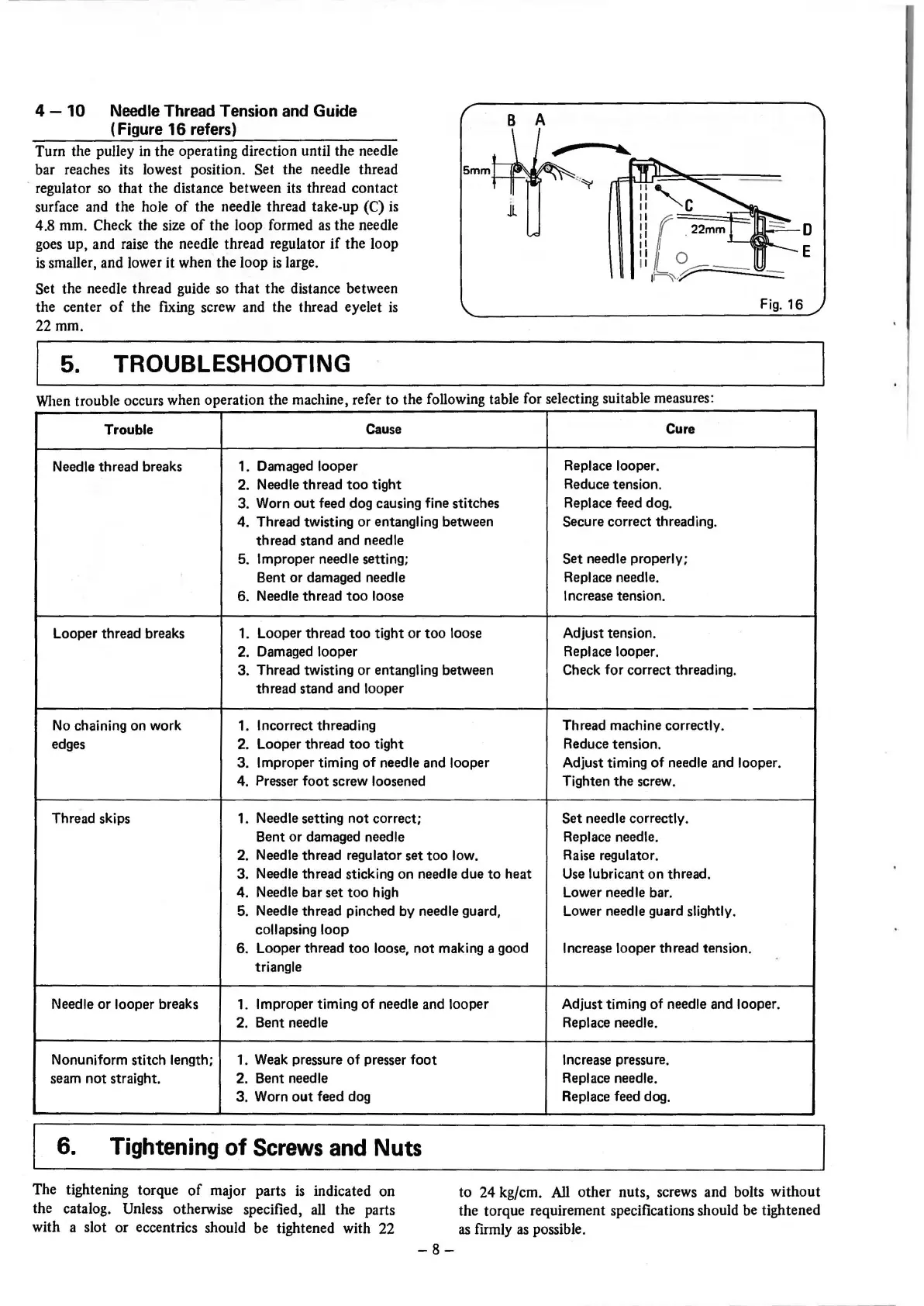

4-10

Needle Thread Tension and

Guide

(Figure

16

refers)

Turn the pulley

in

the operating direction until the needle

bar reaches its lowest position.

Set the needle thread

· regulator so that the distance between its thread contact

surface and the hole

of

the needle thread take-up (C)

is

4.8 mm. Check the size

of

the loop formed as

the

needle

goes up, and raise the needle thread regulator

if

the

loop

is

smaller, and lower

it

when the loop

is

large.

Set the needle thread guide

so

that the distance between

the center

of

the ftxing screw and the thread eyelet

is

22mm.

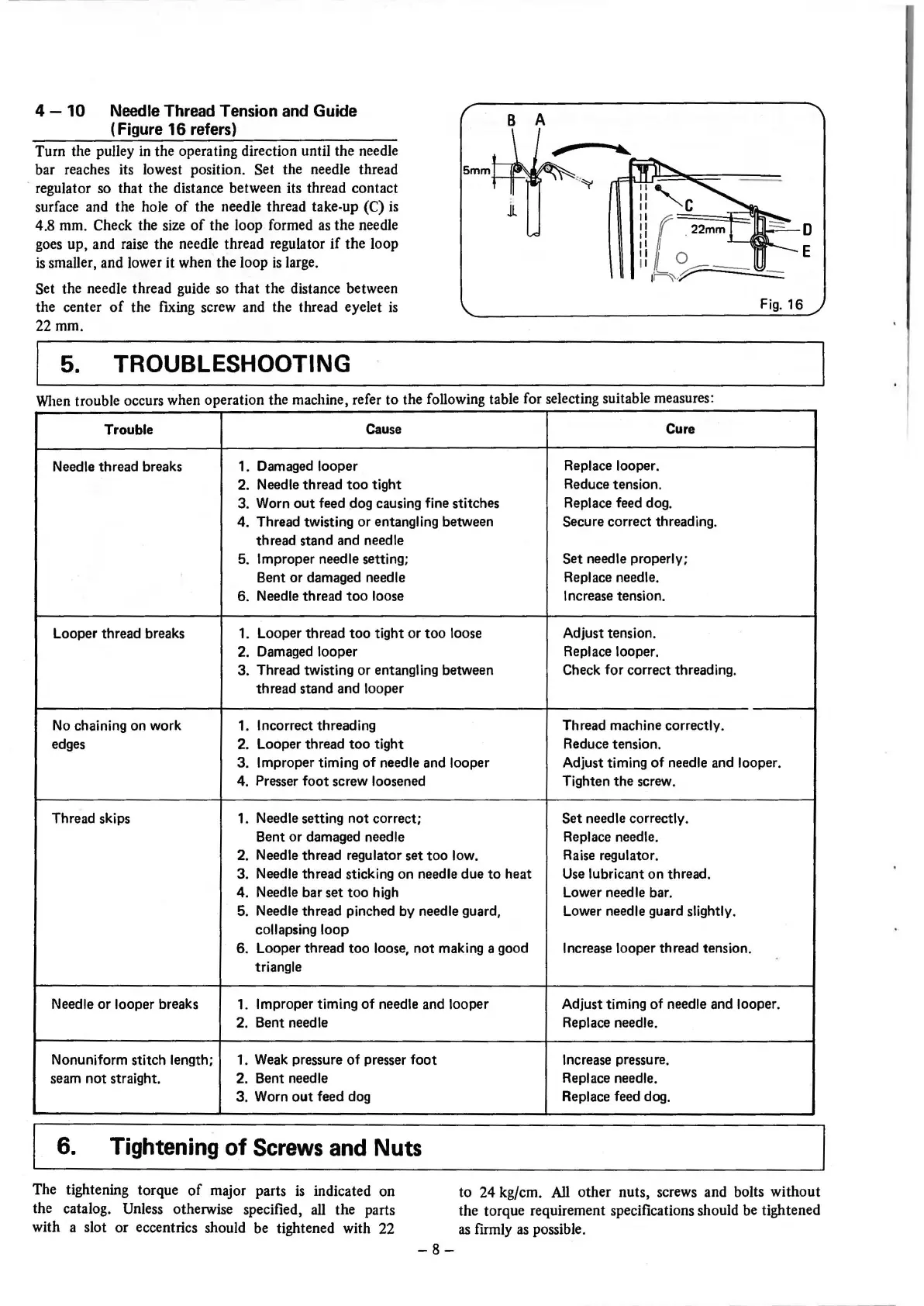

5. TROUBLESHOOTING

8 A

Fig.

16

When trouble occurs when operation the machine, refer

to

the following table for selecting suitable measures:

Trouble

Cause

Cure

Needle

thread breaks

1. Damaged looper

Replace looper.

2. Needle thread

too

tight

Reduce tension.

3. Worn

out

feed dog causing fine stitches

Replace feed dog.

4. Thread twisting or entangling between Secure correct threading.

thread stand and needle

5.

Improper needle setting;

Set needle properly;

Bent or damaged needle

Replace needle.

6.

Needle thread

too

loose

Increase tension.

Looper thread breaks

1.

Looper thread

too

tight or

too

loose Adjust tension.

2.

Damaged looper Replace looper.

3. Thread twisting or entangling between Check for correct threading.

thread stand and looper

No

chaining on work

1.

Incorrect threading Thread machine correctly.

edges

2.

Looper thread

too

tight Reduce tension.

3.

Improper timing

of

needle and looper

Adjust timing of needle and looper.

4. Presser foot screw loosened

Tighten the screw.

Thread skips 1.

Needle setting not correct; Set needle correctly.

Bent or damaged needle Replace needle.

2. Needle thread regulator set

too

low.

Raise

regulator.

3.

Needle thread sticking on needle due

to

heat

Use

lubricant on thread.

4.

Needle bar set

too

high

Lower needle bar.

5.

Needle thread pinched by needle guard, Lower needle guard slightly.

collapsing loop

6. Looper thread

too

loose, not making a good Increase looper thread tension.

triangle

Needle or looper breaks

1. Improper timing of needle and looper Adjust timing of needle and looper.

2. Bent needle Replace needle.

Nonuniform stitch length; 1.

Weak

pressure of presser foot Increase pressure.

seam not straight. 2. Bent needle

Replace needle.

3. Worn

out

feed dog Replace feed dog.

6.

Tightening

of

Screws

and

Nuts

The tightening torque

of

major parts

is

indicated on

the catalog. Unless otherwise specified,

all

the parts

with a slot or eccentrics should be tightened with 22

to

24 kg/em.

All

other nuts, screws and bolts without

the torque requirement specifications should be tightened

as

frrmly

as

possible.

-8-

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...