2. Lubrication

Oil

is

completely drained from the machine

in

our plant

before shipment. Never

fail

to

fill

oil

in

the oil reservoir

before starting the machine. The proper procedure

is

as

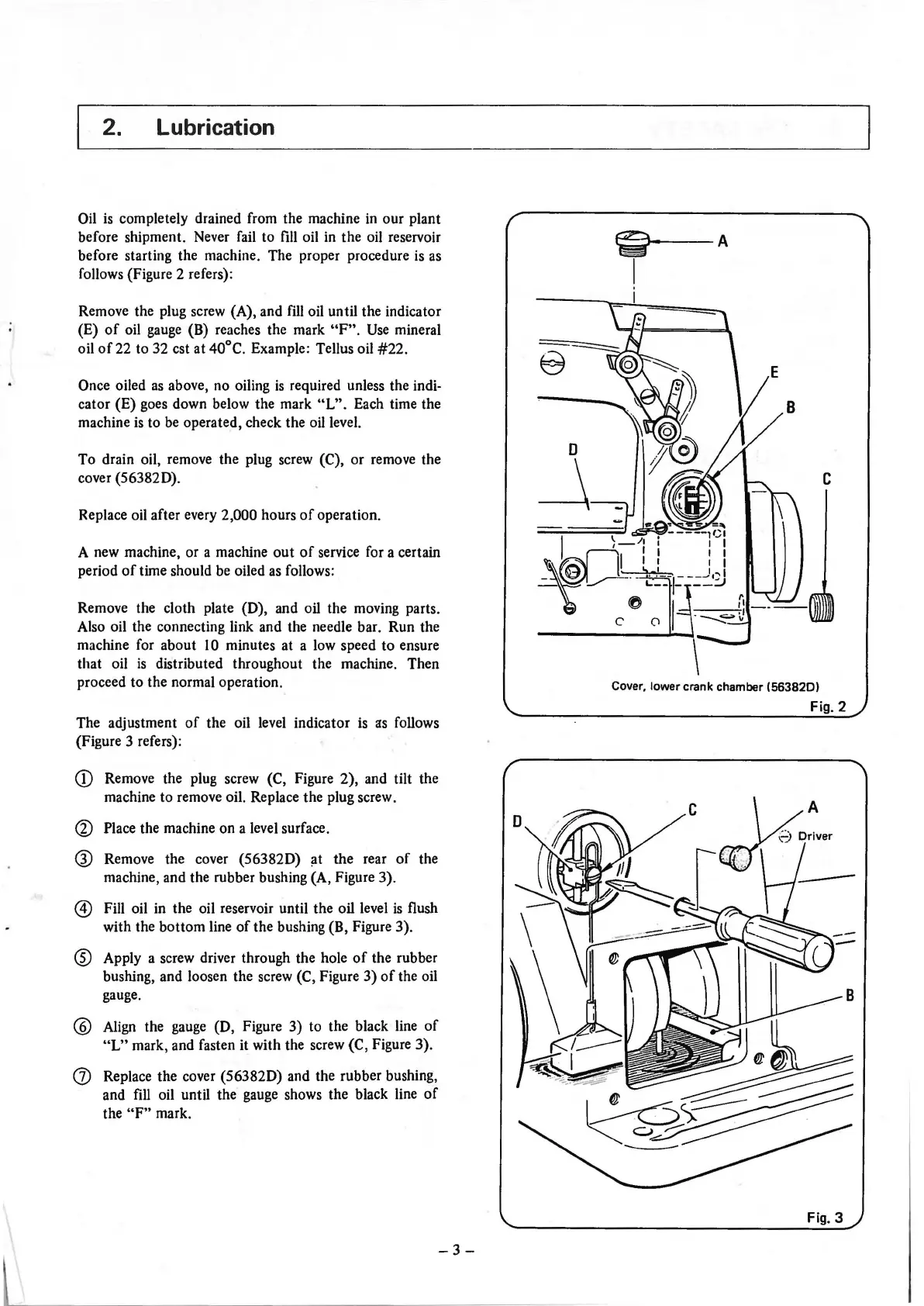

follows (Figure 2 refers):

Remove the plug screw (A), and

fill

oil until the indicator

(E)

of

oil

gauge

(B) reaches the mark

"F".

Use

mineral

oil

of

22 to 32 est at 40°C. Example: Tellus oil

#22.

Once oiled

as

above, no oiling

is

required unless the indi-

cator (E) goes down below the mark

"L".

Each time the

machine

is

to

be

operated, check the oil level.

To drain oil, remove the plug screw

(C), or remove the

cover (563820).

Replace oil after every

2,000 hours

of

operation.

A new machine, or a machine

out

of

service for a certain

period

of

time should

be

oiled

as

follows:

Remove the cloth plate (D), and oil the moving parts.

Also oil the connecting link and the needle bar. Run the

machine for about

10

minutes at a low speed to ensure

that oil

is

distributed throughout the machine. Then

proceed to the normal operation.

The adjustment

of

the oil level indicator

is

as

follows

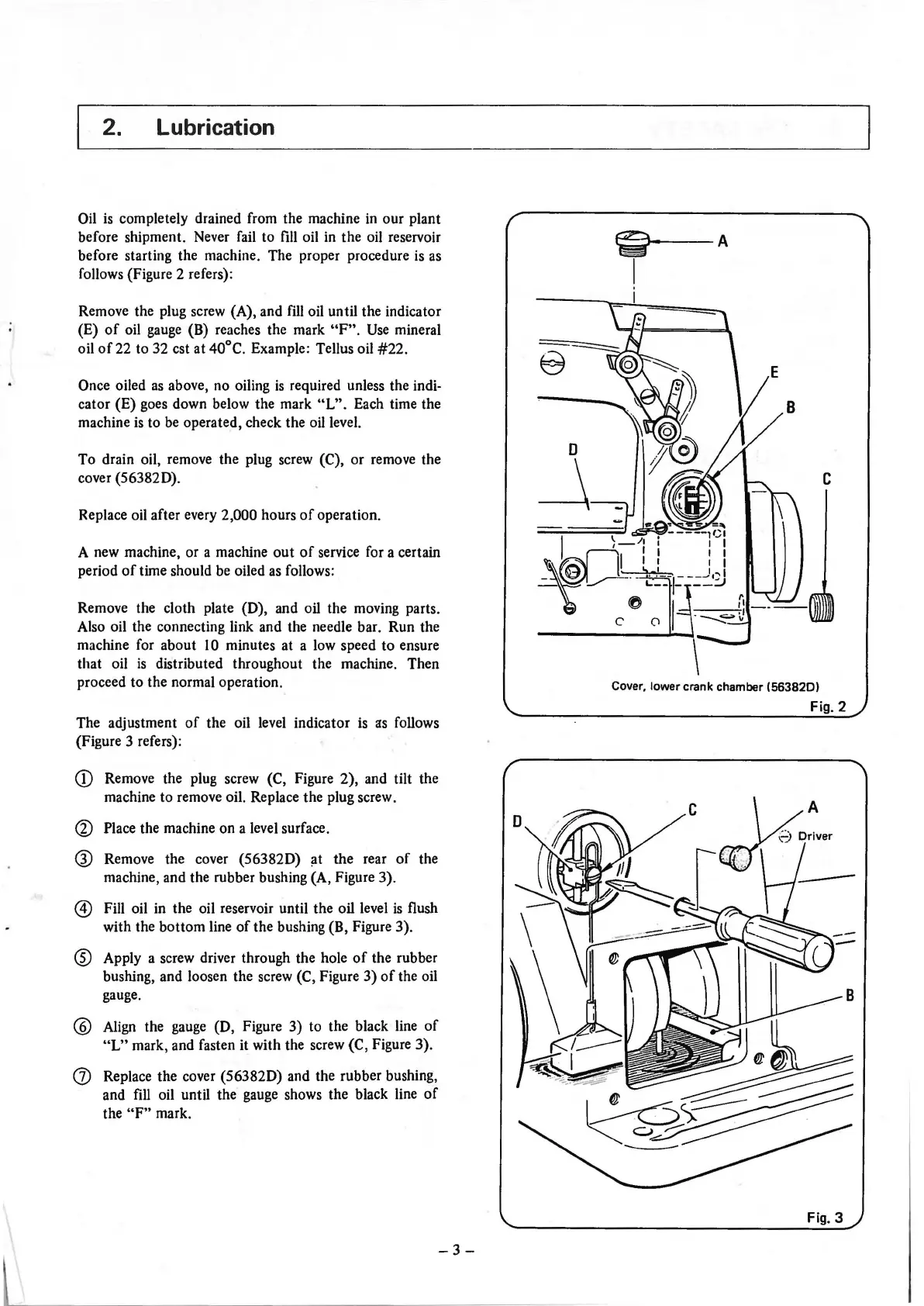

(Figure 3 refers):

Q)

Remove the plug screw (C, Figure 2), and tilt the

machine to remove oil. Replace the plug screw.

Q)

Place the machine on a level surface.

® Remove the cover

(563820)

11t

the rear

of

the

machine, and the rubber bushing (A, Figure 3).

@ Fill oil in the oil reservoir until the oil level

is

flush

with the bottom line

of

the bushing

(8,

Figure 3).

® Apply a screw driver through the hole

of

the rubber

bushing, and loosen the screw

(C, Figure 3)

of

the oil

gauge.

@

Align

the

gauge

(D, Figure 3) to the black line

of

"L"

mark, and fasten it with the screw (C, Figure 3).

(J)

Replace the cover

(563820)

and the rubber bushing,

and fill oil until the gauge shows the black line

of

the

"F"

mark.

-3-

~A

I

Cover, lower crank chamber

(563820)

Fig. 2

Fig. 3

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...