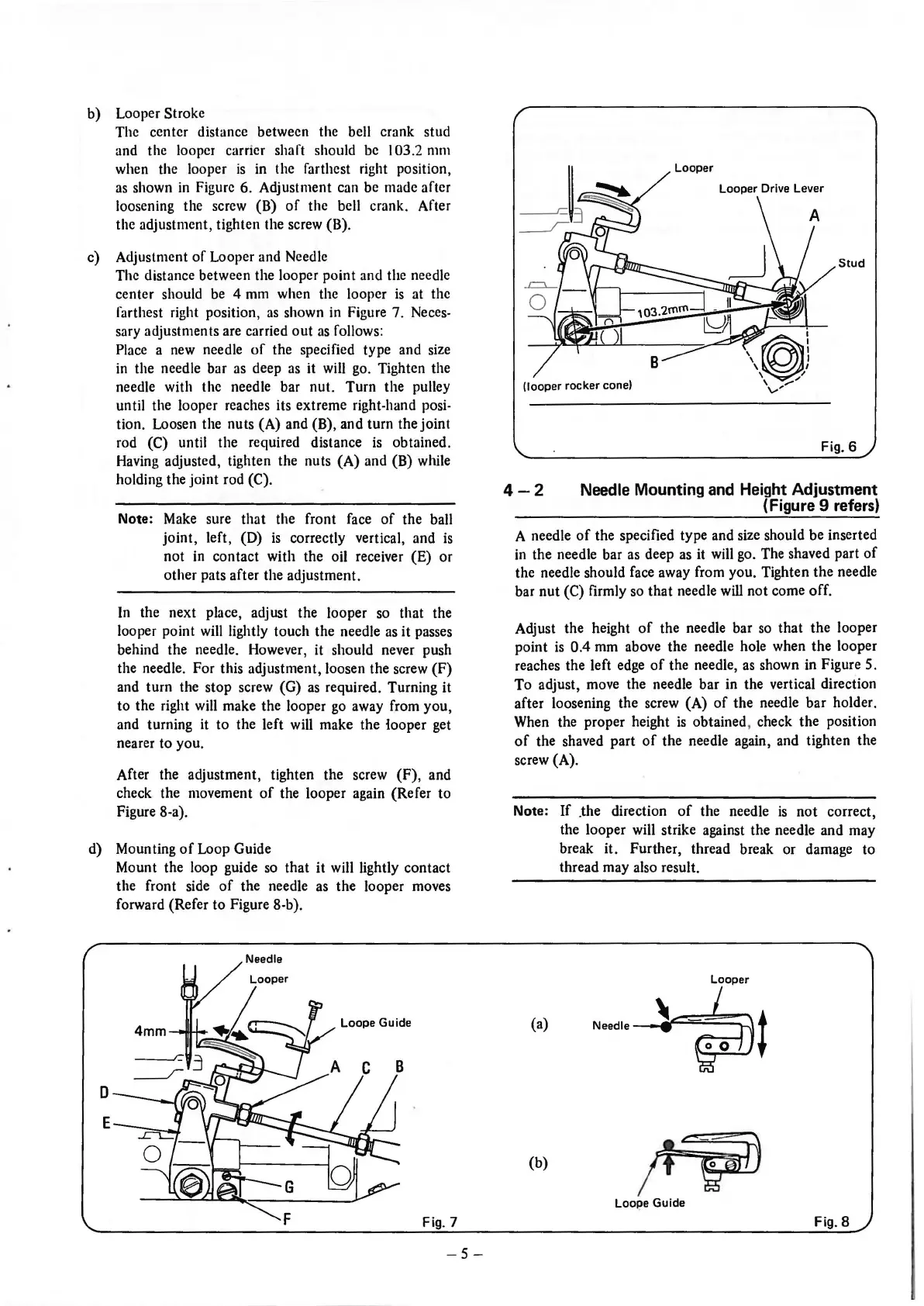

b) Looper Stroke

The center distance between the bell crank stud

and the looper carrier shaft should be

I 03.2 mm

when the looper

is

in the farthest right position,

as

shown

in

Figure 6. Adjustment can be made after

loosening the screw (B)

of

the bell crank. After

the adjustment, tighten the screw (B).

c) Adjustment

of

Looper and Needle

The distance between the looper point and the needle

center should

be

4 mm when the looper

is

at the

farthest right position,

as

shown in Figure 7. Neces-

sary adjustments are carried

out

as

follows:

Place a new needle

of

the specified type and size

in

the needle bar as deep as it will go. Tighten the

needle with the needle bar nut. Turn the pulley

until the looper reaches its extreme right-hand posi-

tion. Loosen the nuts (A) and (B), and turn the joint

rod (C) until the required distance

is

obtained.

Having adjusted, tighten the nuts

(A)

and (B) while

holding the joint rod (C).

Note: Make sure that the front face

of

the ball

joint,

left, (D)

is

correctly vertical, and

is

not in contact with the oil receiver (E)

or

other pats after the adjustment.

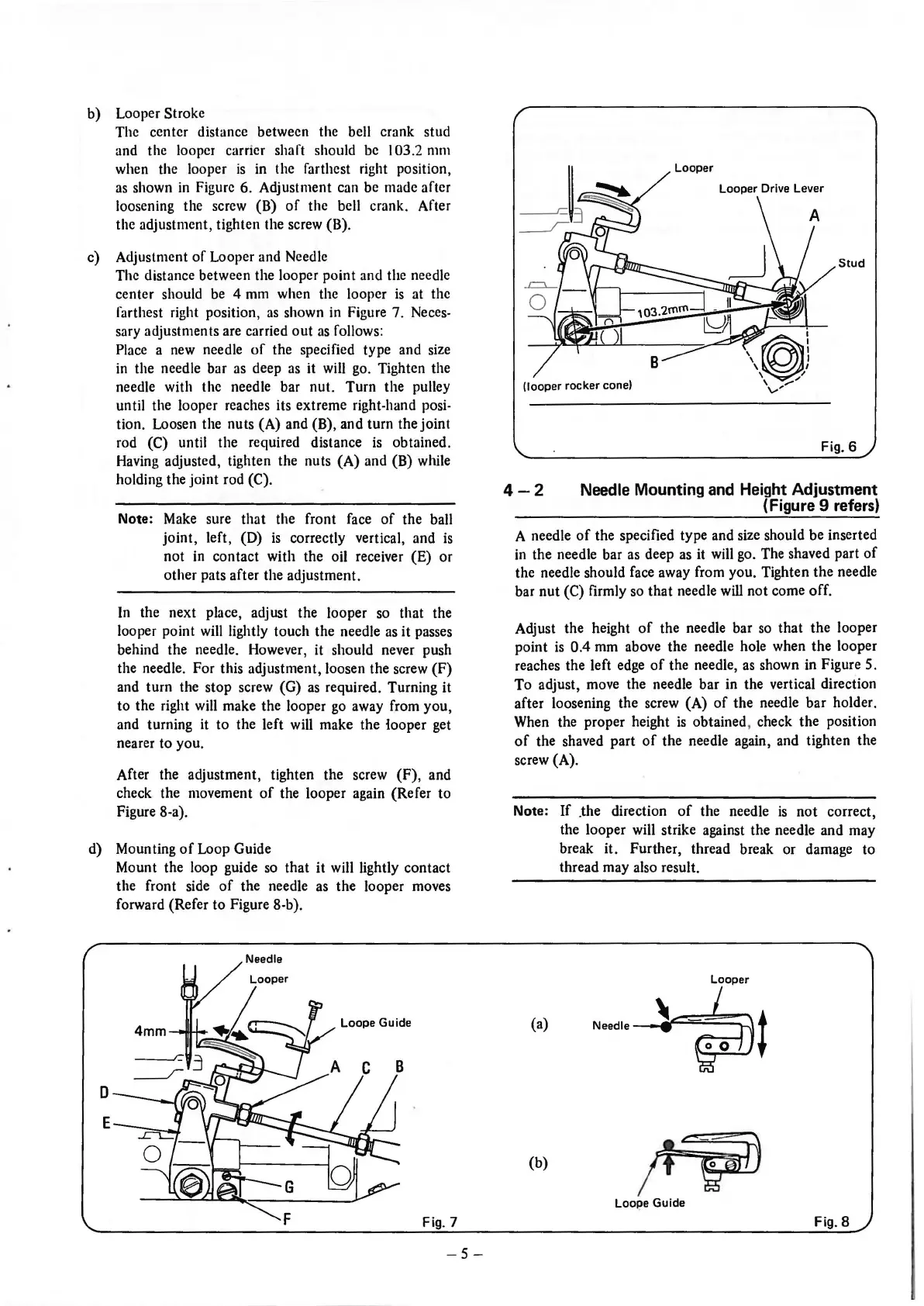

In the next place, adjust the looper so that the

looper point will lightly touch the needle as it passes

behind the needle. However,

it

should never push

the needle. For this adjustment, loosen the screw

(F)

and turn the stop screw (G)

as

required. Turning it

to the right will make the looper

go

away from you,

and turning it to the left will make the iooper get

nearer to you.

After the adjustment, tighten the screw

(F),

and

check the movement

of

the looper again (Refer to

Figure 8-a).

d) Mounting

of

Loop Guide

0

E

Mount the loop guide so that

it

will lightly contact

the front side

of

the needle as the looper moves

forward (Refer to Figure 8-b).

Loope

Guide

Fig. 7

-5-

Looper

Looper Drive Lever

Stud

(looper

rocker cone)

4-2

Fig. 6

Needle Mounting and Height Adjustment

(Figure 9 refers)

A needle

of

the specified type and size should be inserted

in

the needle bar as deep as it will go. The shaved part

of

the needle should face away from you. Tighten

the

needle

bar

nut

(C) firmly so that needle will

not

come off.

Adjust the height

of

the needle bar

so

that the looper

point

is

0.4 mm above the needle hole when

the

looper

reaches the left edge

of

the needle,

as

shown in Figure

5.

To

adjust, move the needle bar in the vertical direction

after loosening the screw (A)

of

the needle bar holder.

When the proper height

is

obtained, check

the

position

of

the shaved part

of

the needle again, and tighten the

screw (A).

Note:

If

_the

direction

of

the needle

is

not

correct,

the looper will strike against the needle and may

break it. Further, thread break or damage to

thread may also result.

(a)

Needle-~~~~==:\

f

\~+

(b)

~

Loope Guide

Fig. 8

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...