11NIBE F1330

Installation / Adjustment

Pipe connections

Pipe connections

General

Pipe installation must be carried out in accordance with

current norms and directives. F1330 can work up to a

return temperature of approx. 58 °C and an outgoing

temperature from the heat pump of approx. 65 °C. When

F1330 is not equipped with shut off valves, these must

be fitted outside of the heat pump to assist future service

work.

Pipe connections (heating medium)

Pipes are connected at the rear of the heat pump. The

necessary safety equipment, shutoff valves (fitted as close

as possible to the heat pump), and the particle filter and

flexible hoses supplied must be fitted.

When connecting to a system with thermostats on all

radiators/coils, a relief valve must be fitted, or some of the

thermostats must be removed to ensure sufficient flow.

The unit is designed to allow hot water production with

one or two heat pump modules. However, this requires

different pipework and a different electrical installation.

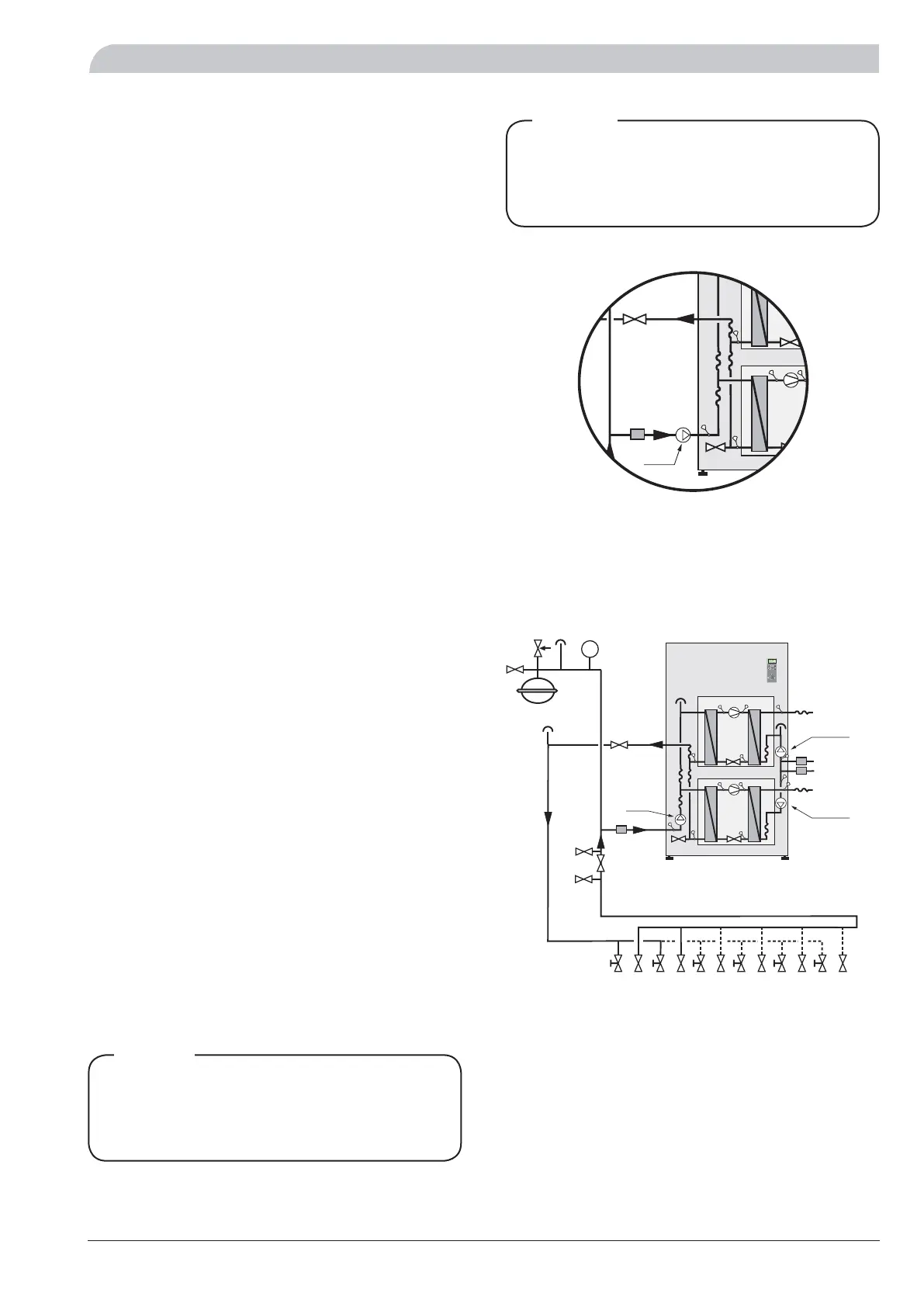

Pipe connections (brine)

When dimensioning the collector, consideration must

be given to the geographical location, type of rock and

ground and the degree of coverage provided by the heat

pump.

When installing the collector hose, ensure it rises constant-

ly towards the heat pump to avoid air pockets. If this is not

possible, install high points to vent the air.

All brine pipes in heated rooms must be insulated against

condensation.

As the temperature of the collector system can fall below

0 °C it must be protected against freezing down to -15 °C.

One litre of ready mixed brine per meter of collector hose

(applies when using PEM-hose 40 x 2.4 PN 6.3) is used as

a guide value when making the volume calculation.

The collector system should to be labelled to show what

antifreeze has been used.

Shut-off valves should be installed as close to the heat

pump as possible. Fit a particle filter to the incoming pipe.

In the case of connection to an open groundwater system,

an intermediate frost-protected circuit must be provided,

because of the risk of dirt and freezing in the evaporator.

This requires an additional heat exchanger.

AV Shutoff valve

BK Rock collector

EXP Level vessel

JK Soil collector

KB-in Brine in

KB-ut Brine out

SF Particle filter

*The brine pump for 60 kW is supplied and installed externally out-

side the heat pump.

The pipe system needs to be flushed out

before the heat pump is connected so that

debris cannot damage component parts.

This applies to both hot and cold sides.

The heat pump’s pipe must not be

soldered directly, due to internal sensors.

Compression ring or press coupling should

be used.

NOTE!

NOTE!

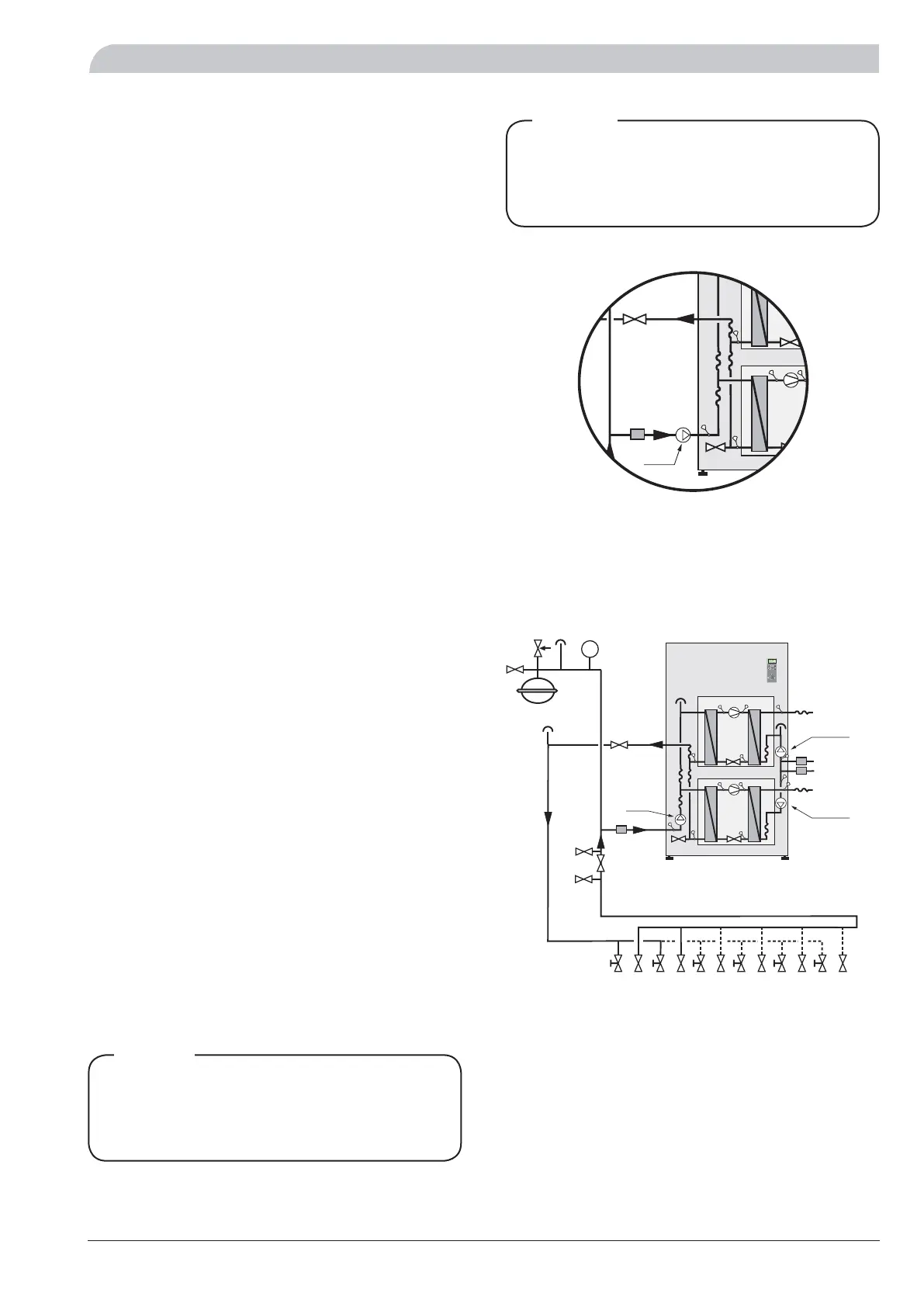

Connecting external brine pump (60 kW only)

The enclosed external brine pump for F1330 -60kW is

installed externally outside the heat pump on incoming

connection (4) (see image above).

B

A

BK / JK

KBP*

VBP-B

VVR

VVF

VBFB

VBRA/VBRB

KBut

KB-in

VBFA

AV

VBP-A

SF

EXP

P

A B I II

A B

13.43

1.0

P

50.0°C

Varmvattentemperatur

Loading...

Loading...