23NIBE F1330

Installation / Adjustment

Description of functions - Basic functions

The outline diagram with docking instructions is

available at www.nibe.eu

Quick guide - menu settings

heat production

Operating mode

The menu is accessible via the operating mode

button. Whether heat production is permitted

is selected here and if so whether the electrical

additional heater may be used.

Menu 2.1 Curve slope [N]

The selected curve slope for the heating curve is shown

here. The value is adjustable between curve 1 and 15,

or in Own curve. The values for own curve are set in

menu 2.6.0. The factory setting is 9.

Menu 2.2 Offset heating curve [N]

The chosen offset for the heating curve is shown here.

The value is adjustable between -10 and +10. NOTE!

The value cannot be changed using the plus and minus

buttons, only by using the Offset heating curve knob on

the Master unit.

If the RCU is connected, the set offset is shown via RCU

between brackets. The actual offset then becomes the

total of the set offset and RCU offset.

Menu 2.3 Min. flow temp. [U]

The set minimum level for the flow temperature to the

heating system is shown here. The calculated supply

temperature never drops below this level irrespective of

the outdoor temperature, curve slope or offset heating

curve. The value is adjustable between 2 and 65 °C.

The factory setting is 15 °C.

Menu 2.4 Max. flow temp. [U]

The set maximum level for the supply temperature to

the heating system is shown here. The calculated sup-

ply temperature never exceeds this level irrespective of

the outdoor temperature, curve slope or offset heating

curve. The value is adjustable between 10 and 80 °C.

The factory setting is 55 °C.

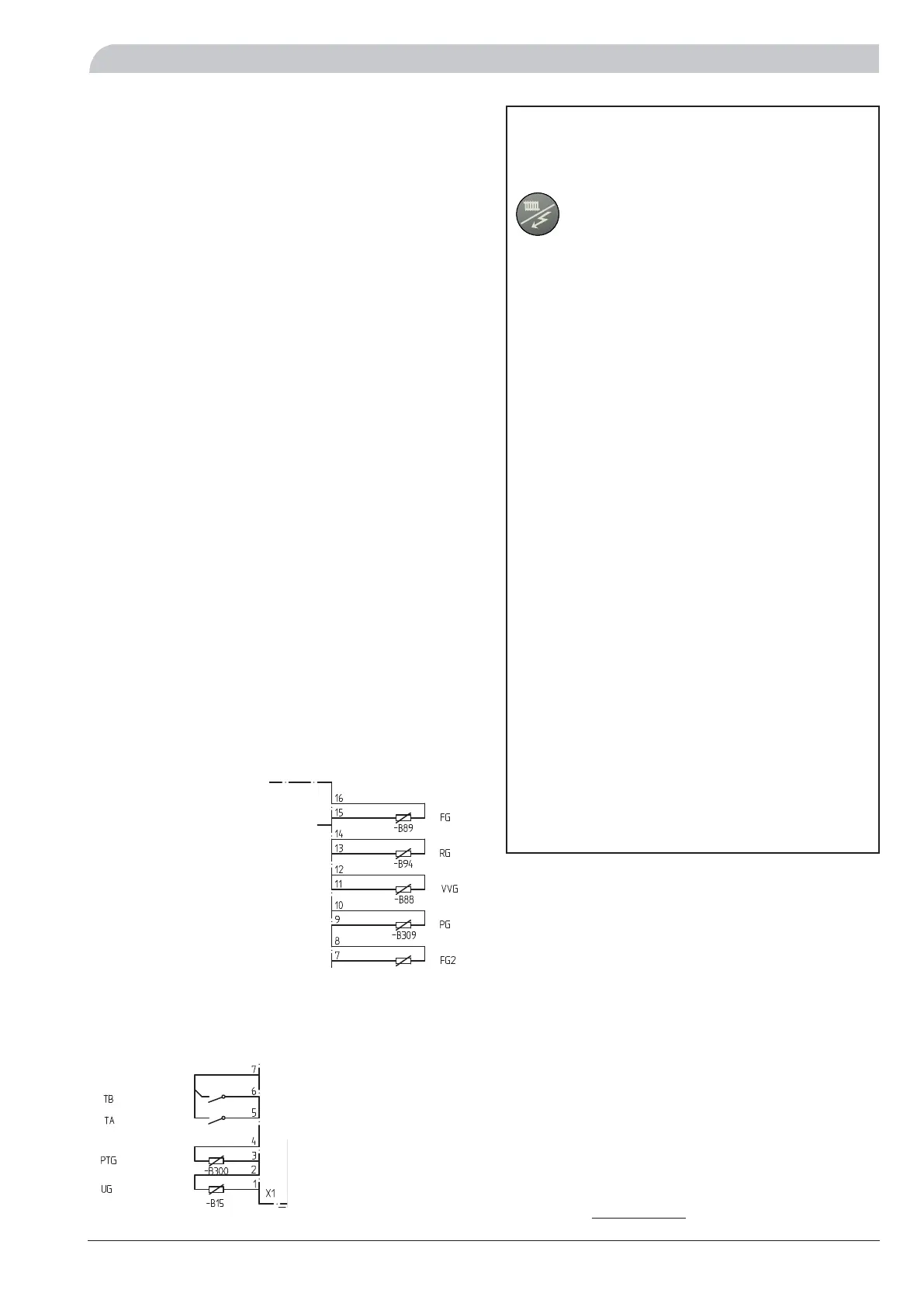

Connection of heat production

The flow temperature sensor (FG) is installed on the flow

line towards the heating system. For a more exact place-

ment see each docking option. The sensor must make

good contact with the measurement area to give the best

function. When a submerged tube is not available, use the

supplied copper tube. The sensor is connected to screw

terminals X4:15 and X4:16 on the EBV-card.

The return line temperature sensor (RG) is installed on

the return line from the heating system. For a more ex-

act placement see the selected docking option. The sen-

sor must make good contact with the measurement area

to give the best function. When a submerged tube is not

available, use the supplied copper tube. The sensor is con-

nected to screw terminals X4:13 and X4:14 on the EBV-

card.

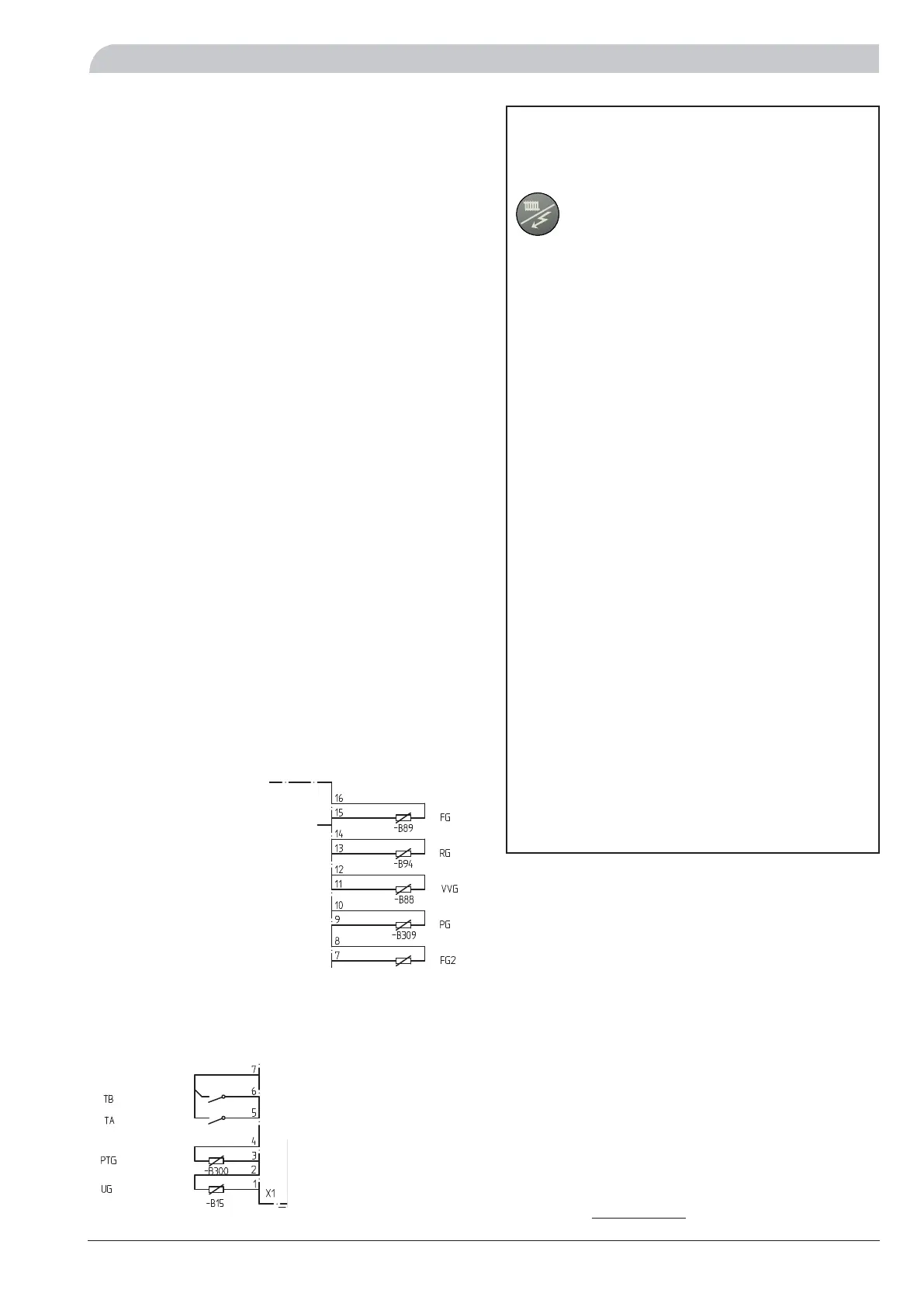

The outside sensor (UG) must be installed in a shaded loca-

tion on a wall facing north or north-west, where it will not

be affected by any morning sun. The sensor is connected

using a two-core cable to the terminal blocks X1:1 and

X1:2 on the EBV-card.

The external heating medium pump (VBP3) control signal

is connected to terminal block X6:1 (230 V), X6:2 (N) (max

0.2 A) on the relay card.

Note that F1330 delivers 230 V control signals intend-

ed to control external contactors and not to drive

pumps.

+EBV-card

X4

+EBV-card

Loading...

Loading...