500

XL4

XL2

CM1

XL8

XL9

XL3

XL1

4 NIBE VVM 500

Transport and storage

NIIBE VVM 500 must be transported and stored upright and dry.

The VVM 500 may, however, be carefully laid on its back when

being moved into a building.

Quick and simple installation

• No extra buffer tank for the heating system is required as

VVM 500 fully controls the heat pump and the heating sys-

tem.

• New control with colour display and USB port.

• Installation help with step by step guide through the start-

up process.

• Automatic setting of flow across heat pump and heating sys-

tem.

• Factory installed components for best operational reliability

and safe installation.

• Complete accessory program.

Maintenance

A minimum level of maintenance is required. Only safety valves

require checking. All essential components can be accessed from

the front. This facilitates service and maintenance.

Installation

VVM 500 is easy to install. All pipe connections are easily accessi-

ble. This is especially useful for the replacement market.

Equipment

VVM 500 is equipped with a drain and reversing valve. In addi-

tion, VVM 500 is equipped with climate controlled automatic by-

passes with outdoor and flow sensors, shunt valve, charge and

circulation pump.

Expansion vessel

Dimensioned as 5 % of the maximum system volume (that is 500

litres plus maximum circulating volume in the hot circuit).

Design

VVM 500 is equipped with an intelligent control. This makes for

easy operation at the same time as always enabling the indoor

module to run as efficiently as possible. The control manages the

automatic bypass and circulation pumps. Current temperatures

and set values can be shown on the display.

The insulation consists of moulded, freon-free polyurethane

which is equivalent to approximately 200 mm mineral wool.

The outer casing is of white powder-coated steel plate.

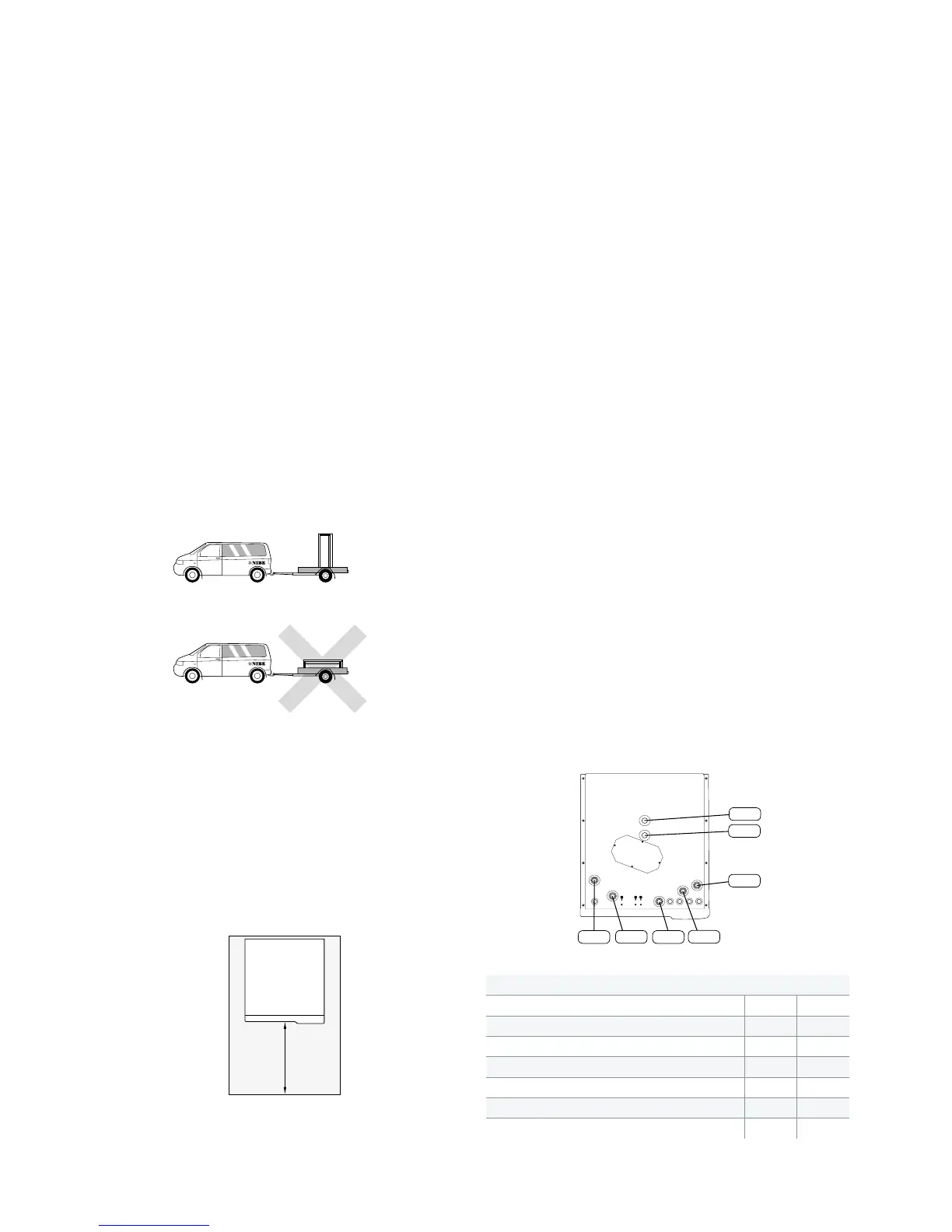

Pipe dimensions

Assembly

Position VVM 500 on a firm base that can bear its weight, prefer-

ably on a concrete floor or foundation. Use the product's adjust-

able feet to obtain a horizontal and stable set-up.

The area where VVM 500 is located must be equipped with floor

drainage.

Installation area

Leave a space of 500 mm in front of the product. All service on

VVM 500 can be carried out from the front.

NOTE! Leave 10-25 mm free space between the indoor module

and the wall behind for routing of cables and pipes.

Connection

CM1 Expansion tank (connection) Ø G20 internal

XL1 Heating medium, flow line Ø G25 internal

XL2 Heating medium, flow line Ø G25 internal

XL3 Cold Water リ G25 internal

XL4 Hot Water Ø G25 exernal

XL8 Connection, docking in heating medium Ø G25 internal

XL9 Connection, docking out heating medium Ø G25 internal

GOOD TO kNOW ABOUT NIBE

™

VVM 500

Loading...

Loading...