SOL 3 / SOL 5 W / BDC 3122 / BDC 3140 / E-VAC3000

9

03/2009

GB

[ NOTE ]

Ifthereisonlyadustdepositontheseparator(1)allow

thedusttodropthroughthecentralhole.

The separator (1) should rst be disassembled in order to be

perfectly cleaned:

■ Use the lever (2) to remove the lid (3) together with the

lter.

■ Unscrew the two screws (4) and remove it from the

container.

Replace the part if it is excessively worn. Assemble the

components in the reverse order of disassembly.

Vacuum cleaner disposal

Dispose of the vacuum cleaner in compliance with the laws in

force.

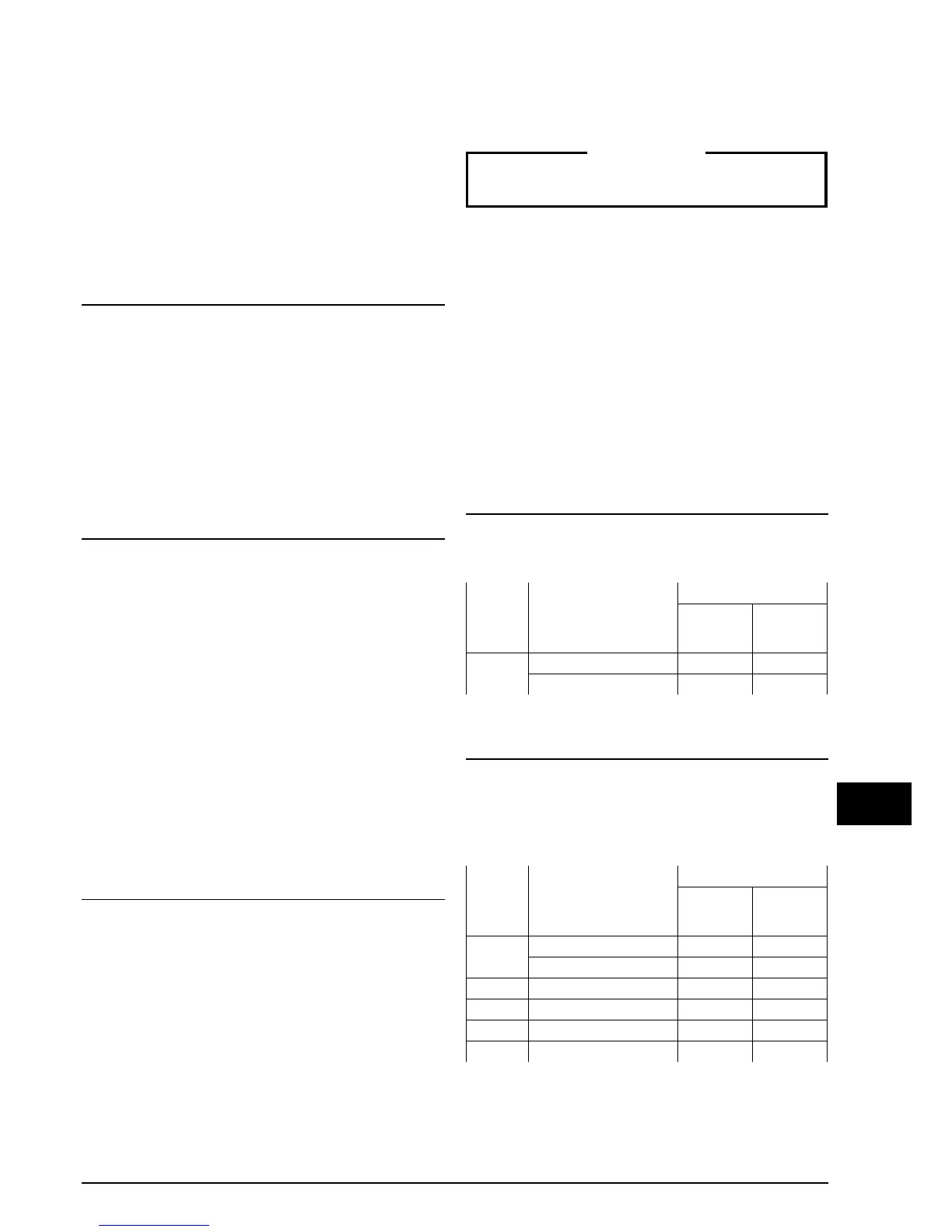

Wiring diagrams

Basic vacuum cleaner

Figure 17

1 Plug

2 Vacuum cleaner

3 Circuit breaker

Name Part

Code

SOL 3

BDC 3122

SOL 5 W

BDC 3140

E-VAC3000

Q1

Circuit breaker 8 391156 8 391157

Box for Q1 8 391052 8 391052

Wet vacuuming kit

Figure 18

1 Power supply

2 Transformer

3 Liquid sensor

4 Auto release

5 Vacuum cleaner

6 Circuit breaker

Name Part

Code

SOL 3

BDC 3122

SOL 5 W

BDC 3140

E-VAC3000

Q1

Circuit breaker 8 39915 8 39916

Handle for Q1 8 39954 8 39954

B1 Auto release 8 391142 8 391142

PR1 Pressure switch 8 40841 8 40841

F1 - F2 Fuse holder 8 39244 8 39244

TR1 Transformer 8 391050 8 391050

Motor cooling fan inspection and cleaning

Periodically clean the motor cooling fan to prevent the motor

from overheating, especially if the vacuum cleaner is used in

a dusty place.

Seal inspection

Figure 14

1 Hose

2 Hose

■ Hoses check

Make sure that connecting hose (1) is in a good condition

and correctly xed.

If the hose is damaged, broken or badly connected to the

unions, it must be replaced.

When sticky materials are treated, check for possible

clogging along the hose (2), in the inlet and on the bafe

plate inside the ltering chamber.

Scrape the inlet from the outside and remove the

deposited waste as indicated in the gure.

Figure 15

1 Gasket

2 Screws

3 Filtering chamber

■ Filtering chamber tightness check

If the gasket (1) between the container and the ltering

chamber (3) fails to guarantee tightness:

▪ Loosen the four screws (2) that lock the ltering

chamber (3) against the vacuum cleaner structure.

▪ Allow the ltering chamber (3) to lower down and

tighten the screws once it has reached the tightness

position (2).

The gasket (1) must be replaced if it is torn, cut, etc...

Replace the gasket (1) if the degree of tightness is still

not optimum.

Separator cleaning and replacement (if

equipped)

Figure 16

1 Separator

2 Lever

3 Cover

4 Screws

Loading...

Loading...