G

Adjustment / Test

NEPTUNE 1&2_EN_Ver.2.1_45/2014 100

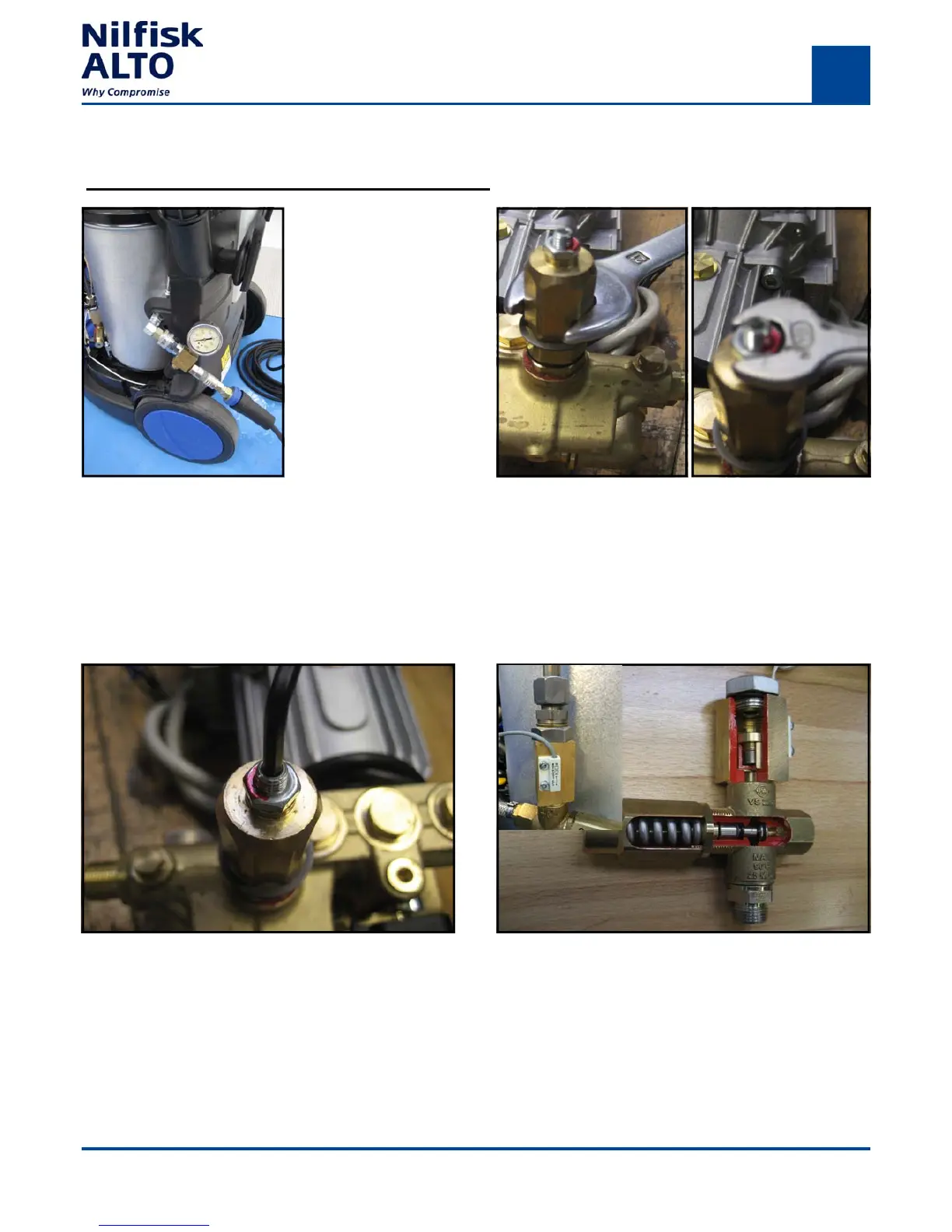

The safety valve is preadjusted from factory..

To check the function, the spring must be re-

leased until the valve is leaking and then tur-

ned back to the starting point.

The reed switch on the flow switch housing

must be pushed ALL THE WAY UP, before

the two screws are tightened.

Fig.G.8: Safety valve and flow switch.

Operating / Cut Off - Pressure Neptune 2 Special

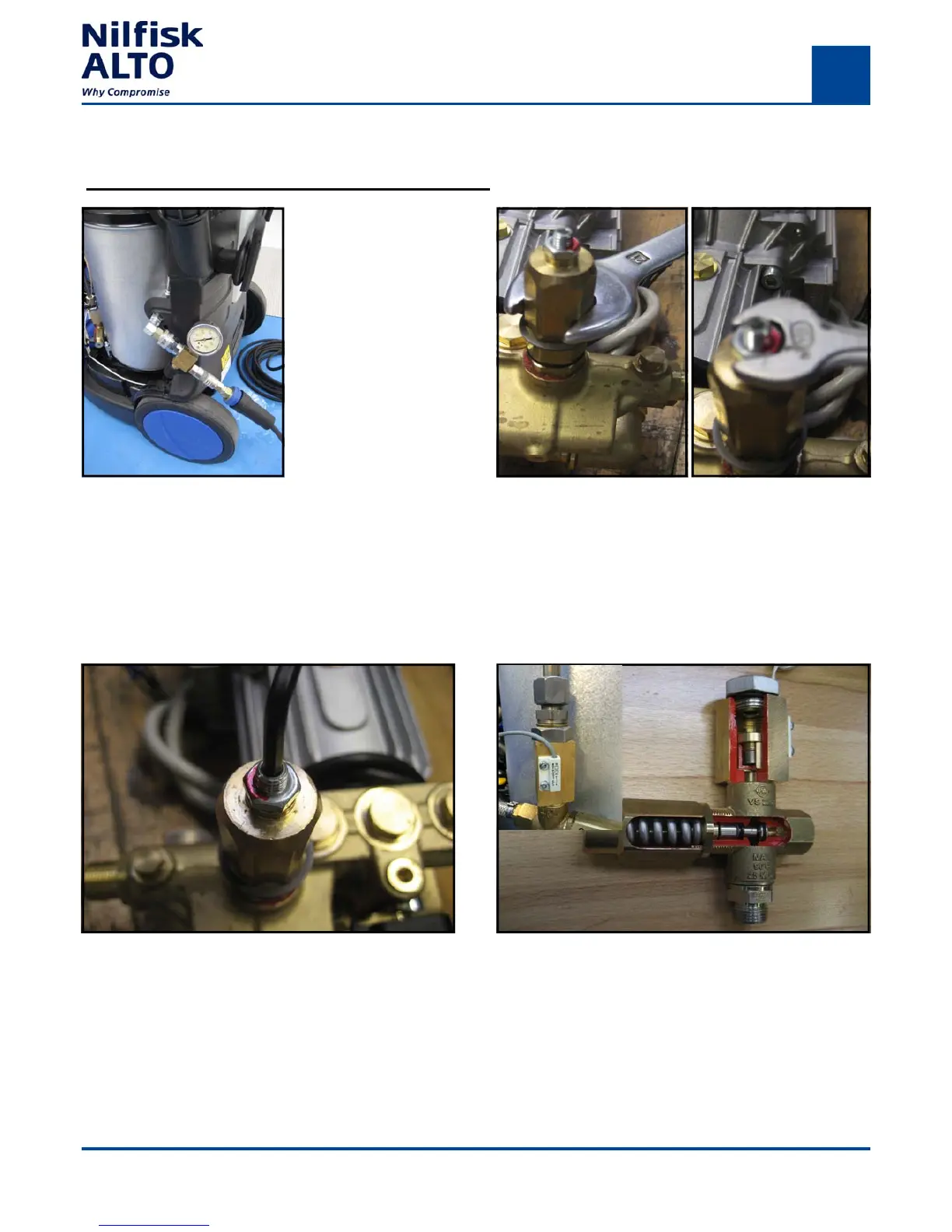

Fig.G.5: Pressure setting 1

Mount test pressure gauge between HP-outlet

and hose to get an accurate reading.

Run the machine with the correct nozzle.

Pressure should correspond with technical data

chapter A.

Close gun and note cut-off pressure.

Make sure the end stop connector is tightened

Loosening counter nut using a 10mm spanner.

Use the gun to get a quick cut-off.

Open gun and read the pressure.

Adjust to maximum pressure minus X % or

as pressure @ Gun in technical data.

Clockwise for higher cut-off pressure.

Counter clockwise for lower cut-off pressure.

Tighten the counter nut after adjustment.

Fig.G.6: Pressure setting 1

Fig.G.7: Pressure setting 1

Loading...

Loading...