3. Storage, Preparation,

Installation

-10- B1000 www.nord.com

3.3 Preparing for installation

The drive unit must be inspected and may only be installed if no transportation damage or leaks

are visible. In particular the radial seals and the sealing caps must be inspected for damage.

In applications where an incorrect rotational direction may result in damage or potential risk, the

correct rotational direction of the drive shaft is to be established by test running the drive when

uncoupled and guaranteeing such for subsequent operation.

Gears with integrated return stops are marked with arrows on the driven/driving sides. The

arrows point in the rotation direction of the gear unit. It must be ensured, when connecting the

motor and during motor control, that the gear unit can only operate in the rotation direction, e.g.

by means of a rotary field test. (For further details, please refer to Catalogue G1000)

Attention!

With gear units with an integrated back stop, switching the drive motor to the blocked rotation

direction, i.e. incorrect rotation direction, can lead to gear damage.

Ensure that no aggressive or corrosive substances are present in the area surrounding the

installation site or are subsequently expected during operation, which attack metal, lubricants or

elastomers. In case of doubt, please contact Getriebebau NORD and take the recommended

action.

Oil expansion tanks (Option OA) must be fitted in accordance with the attached works standard

WN 0-530 04. For gear units with an M10x1 vent plug, works standard WN 0-52135 must be

observed.

Oil expansion tanks (Option OA) must be fitted in accordance with the attached works standard

WN 0-521 30.

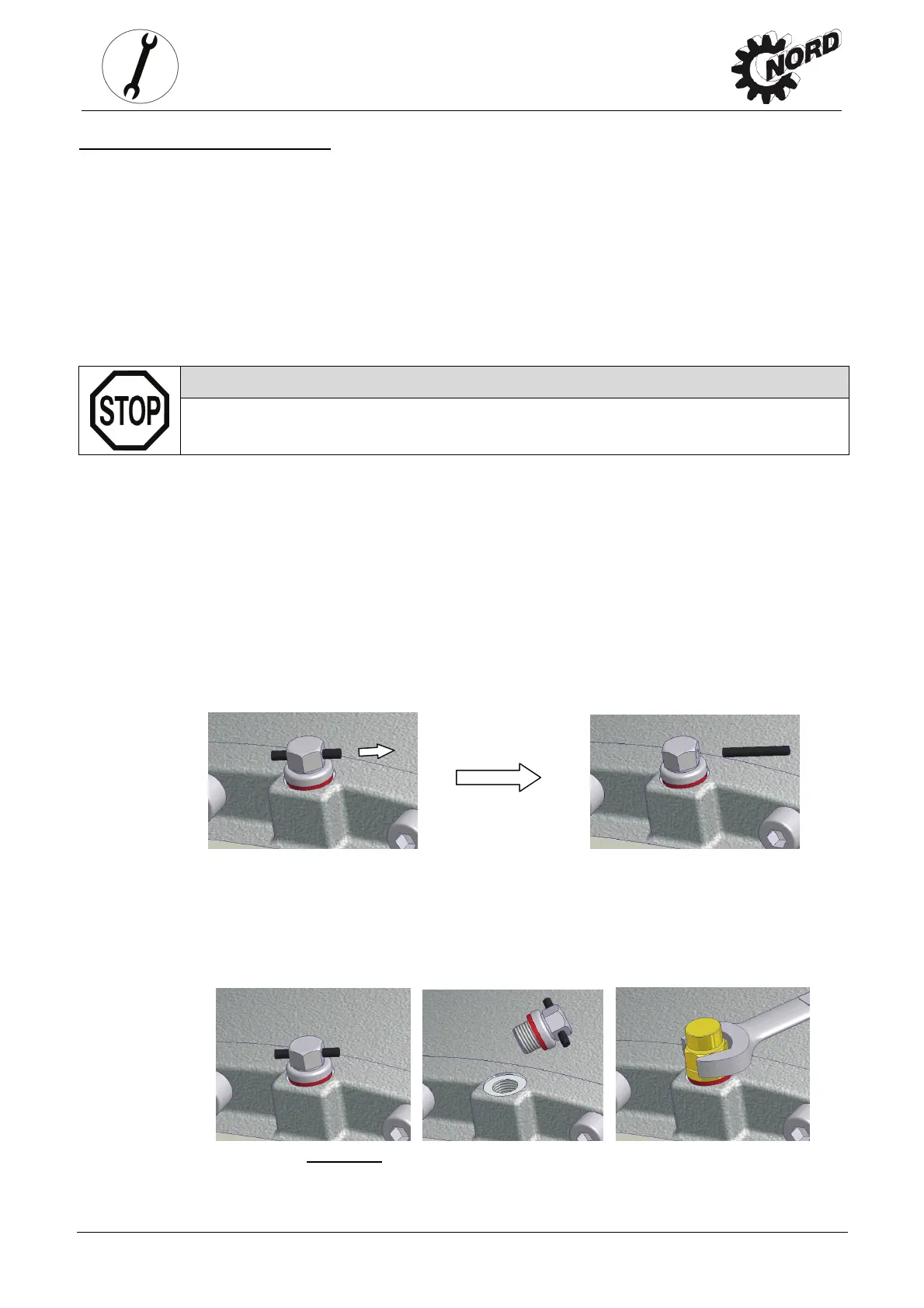

If a vent plug is fitted, the sealing cord must be removed from the vent plug before

commissioning. Position of the vent plug: see Section 6.1.

Figure 3-1: Activating the vent plug

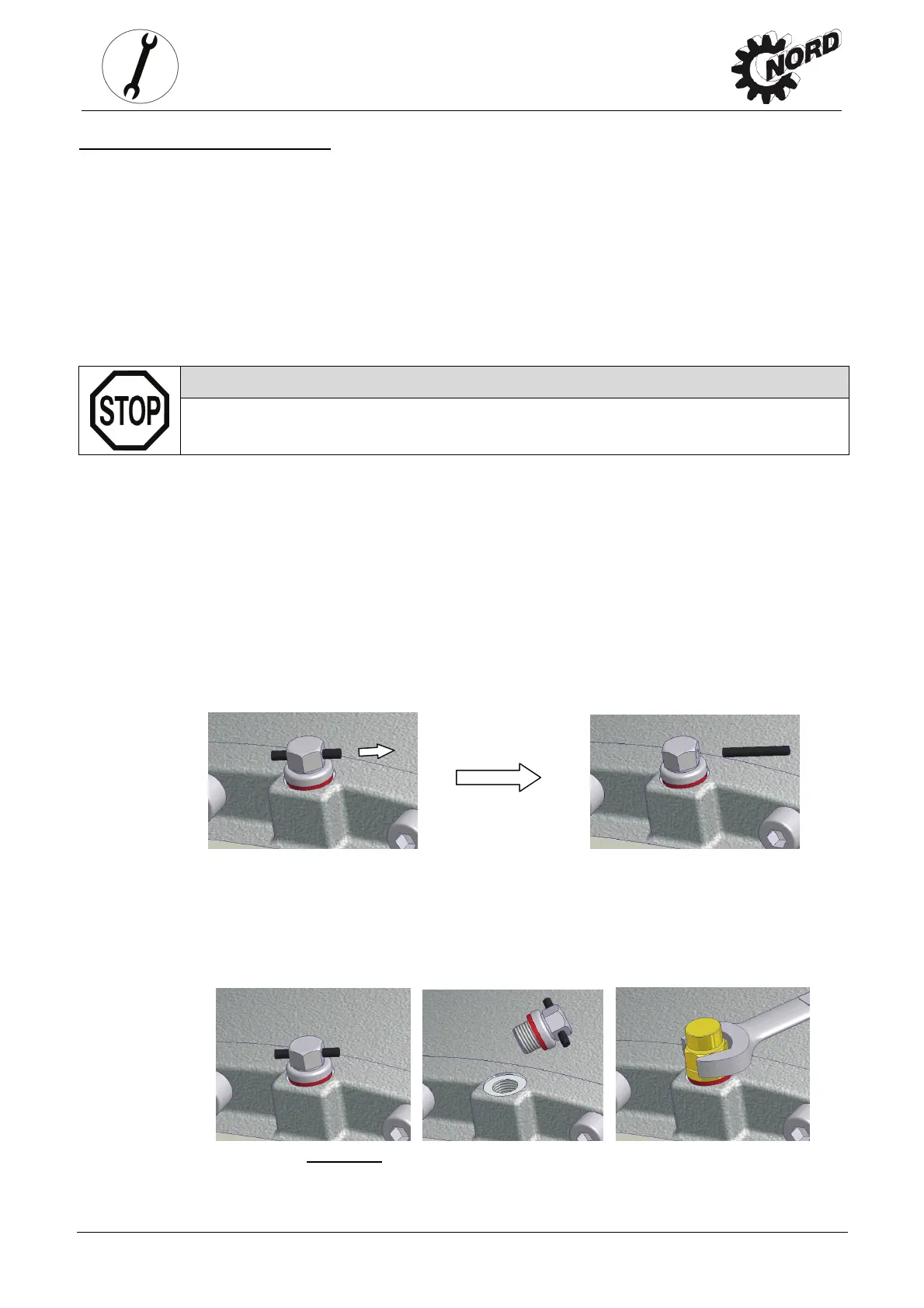

If in case of drive units with the option DR the pressure vent is not fitted, the vent plug must be

replaced with the supplied pressure vent before commissioning. This is achieved by screwing

out the vent fitting and replacing it with the pressure vent and seal (refer to Section 6.2 for torque

values). Double gear units consist of two single units and are equipped with 2 oil chambers and

2 pressure vents.

Figure 3-2:

Removing vent plug and fitting the pressure vent

Loading...

Loading...