Converting an FP-200 Extrusion Gun to an FP-200 Swirl Gun

11

Part 237494_02

E 2012 Nordson Corporation

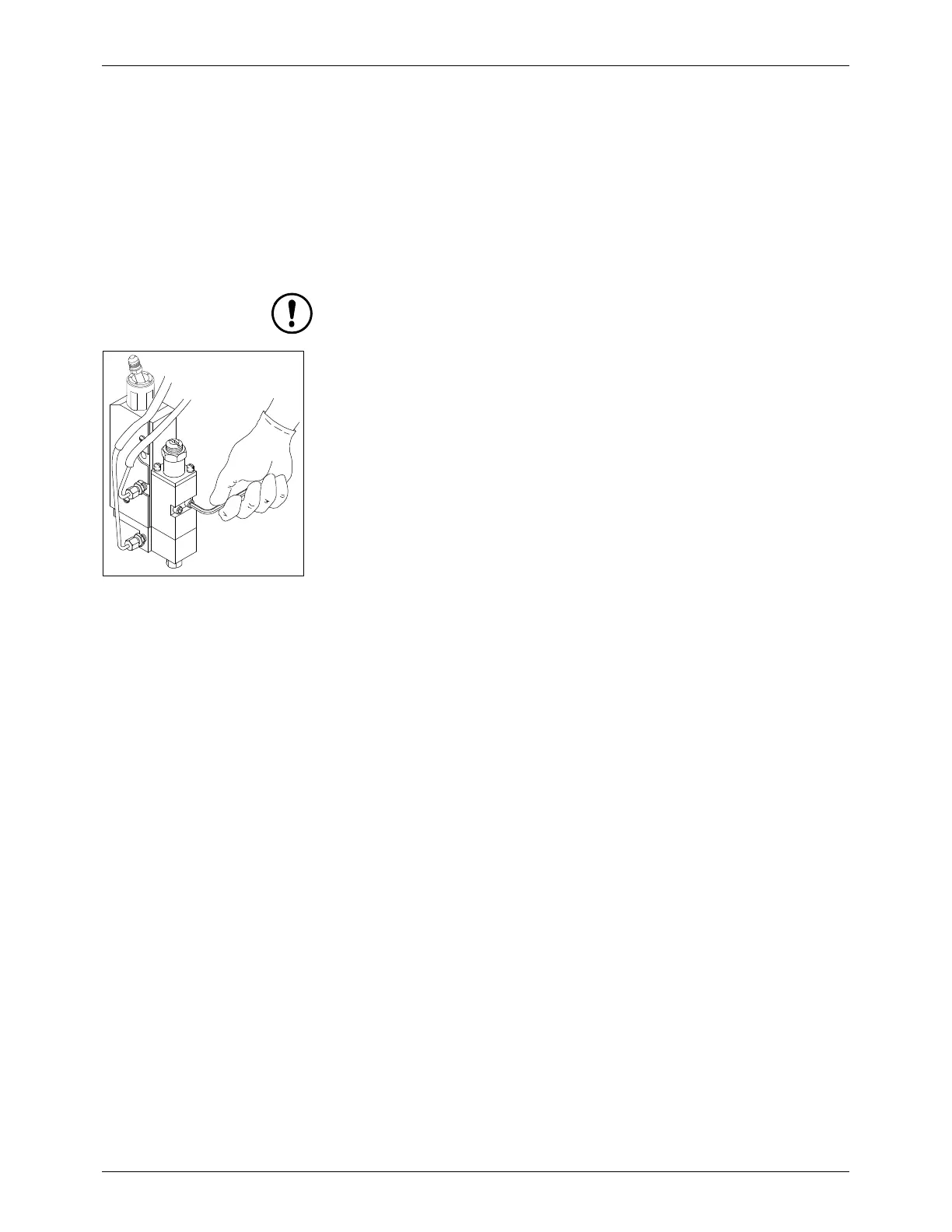

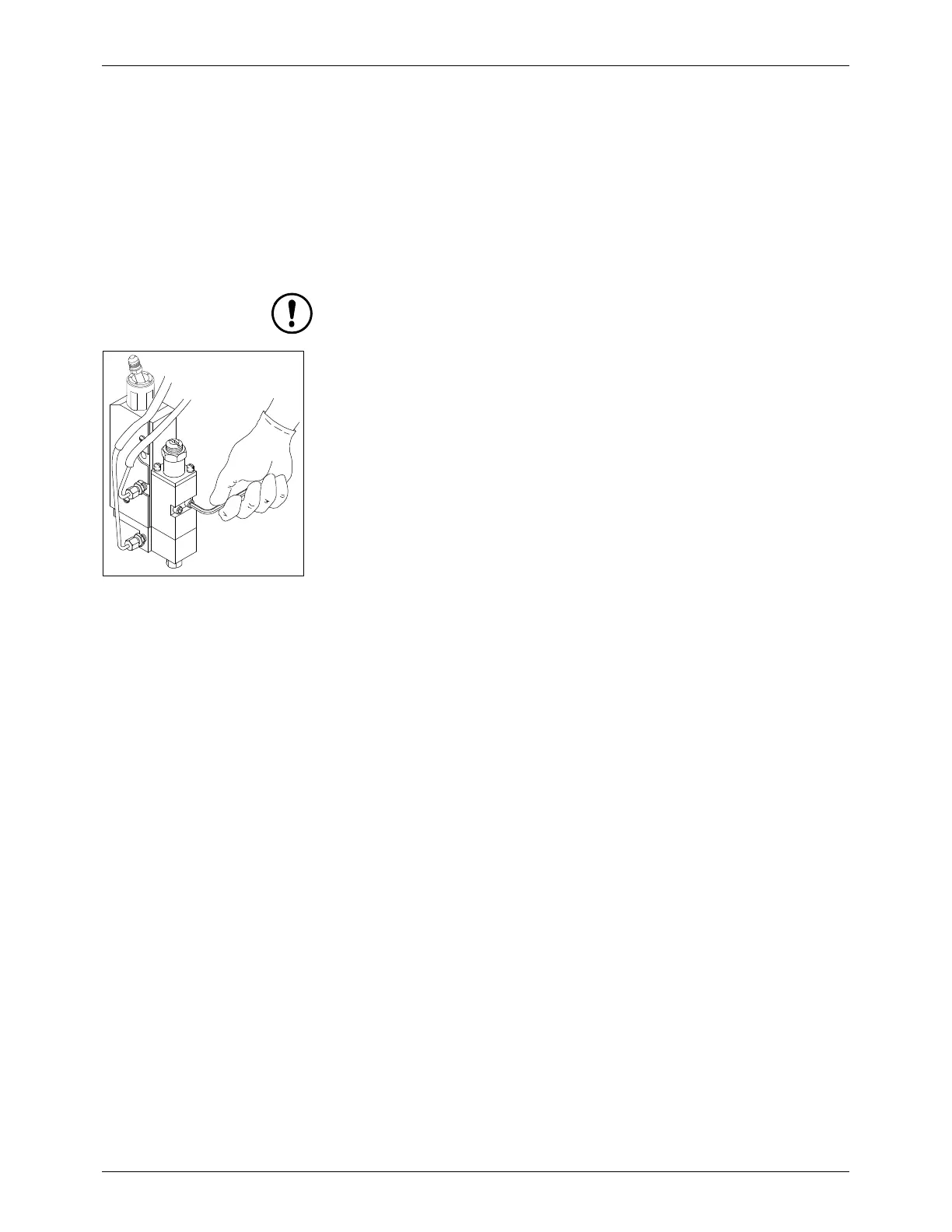

10. Install the new CF-200 wide pattern module on the service block as

follows:

a. Remove the old module.

b. Lubricate the new module's o-rings.

c. Wipe off any hot melt material on the service block, especially around

the air passages.

d. Apply anti-seize lubricant to the two module socket-head screws.

CAUTION: Do not overtighten. Overtightening can strip the threads.

e. Use the socket head screws to secure the new module to the service

block. Torque the screws to 30 in-lb.

NOTE: For best results, torque the screws again after the applicator

reaches operating temperature.

NOTE: Nozzles must be ordered separately. Refer to Parts.

11. Install the swirl gun heat shield as follows:

a. Disconnect the swirl and extrusion air lines by unthreading the tube

nuts at the male connectors on the service block and air manifold.

b. Wrapthecoveraroundthemoduleandserviceblockandfastenit.

c. Reconnect the swirl and extrusion air lines.

Figure 6 Installing the New

Module

12. Reinstall the auxiliary guide handle.

13. Go to Restoring the System to Normal Operation.

Loading...

Loading...