30

ROTARY JOINT MAINTENANCE

HYDRAULIC ROTARY JOINT

ASSEMBLY

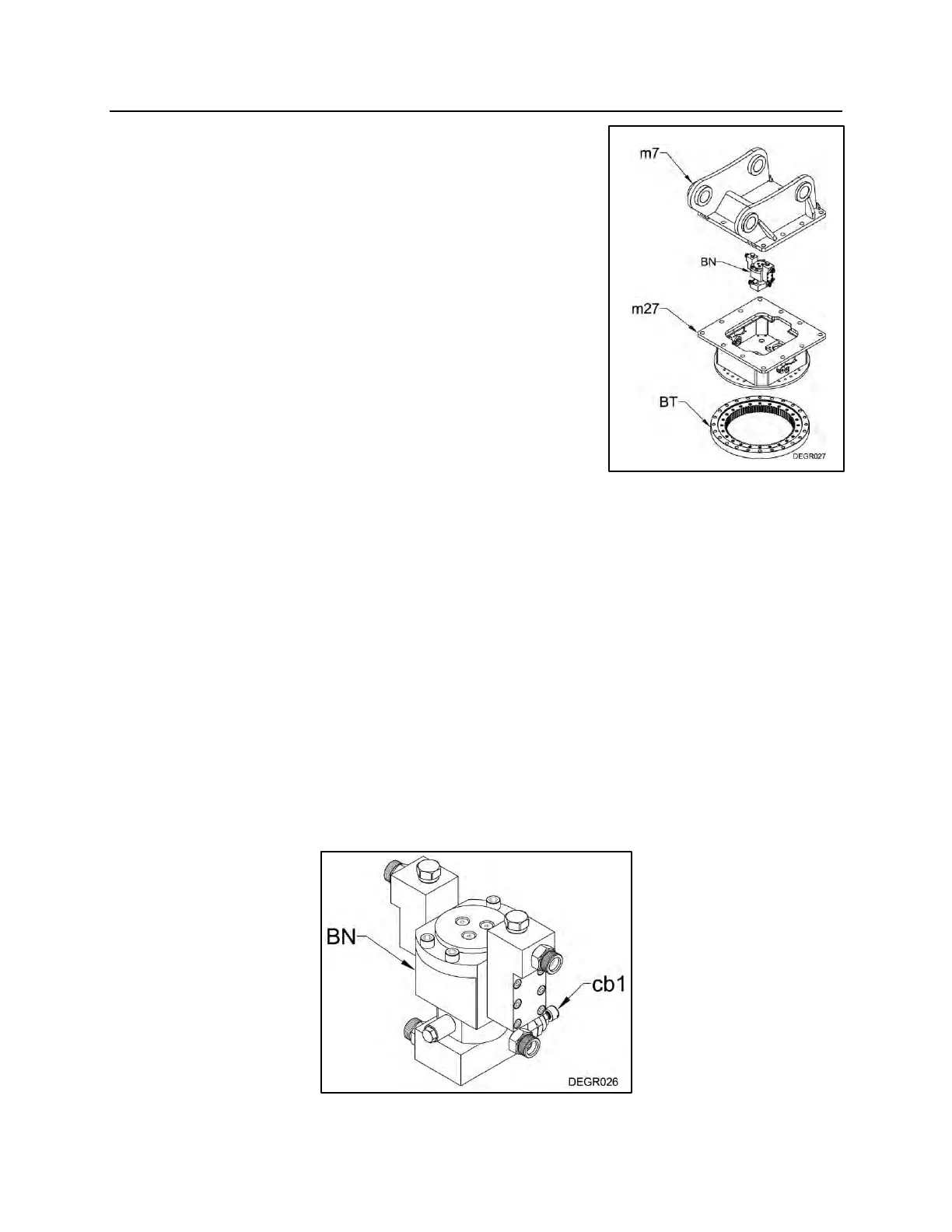

The hydraulic rotary joint assembly (BN) is mounted inside

the swivel top assembly (m27) which is under the top

bracket (m7) that pins to the carrier and is bolted to the

slewing ring (BT) which rotates the Demolition Grab’s

main frame. Hydraulic oil for both open and close

operations passes through it. The rotary joint assembly

consists of two main parts, the “Spindle Case”, which

contains the oil seals and the “Spindle”, which rotates the

Demolition Grab’s main frame.

LEAKAGE OF THE SEALS

External leakage or internal (bypassing) of hydraulic oil

will require the replacement of the seals in the rotary joint

assembly. For external leakage, please review the seal replacement procedure in the

next section. If internal leakage is suspected, please proceed to the “TESTING THE

ROTARY JOINT SEALS FOR INTERNAL LEAKAGE” section.

TESTING THE ROTARY JOINT SEALS FOR INTERNAL

LEAKAGE

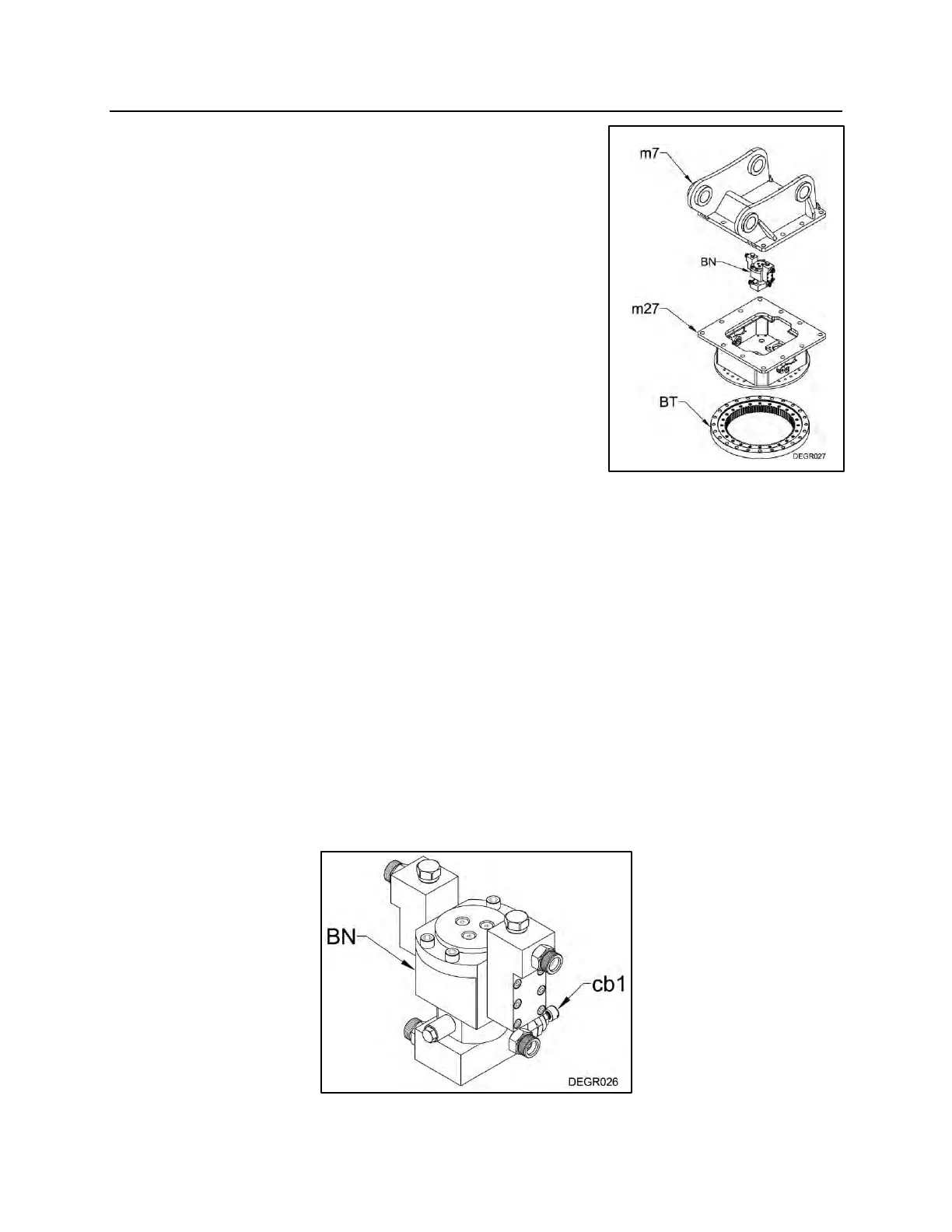

If internal seal leakage is suspected, before disassembling the rotary joint assembly

(BN), the counterbalance valve cartridge (cb1) pressure setting should be checked.

Internal leakage will most likely prevent the unit from reaching relief pressure in the

close function. The relief cartridge is located below the rotary joint in a block that the

hose connections to the cylinder are located. Access to the relief valve cartridge is

through the cover plates of the swivel top assembly.

NOTE: Before attempting to adjust the relief setting, please check that the relief valve

cartridge has not loosened in the block.

Loading...

Loading...