- 19 -

LUBRICATION

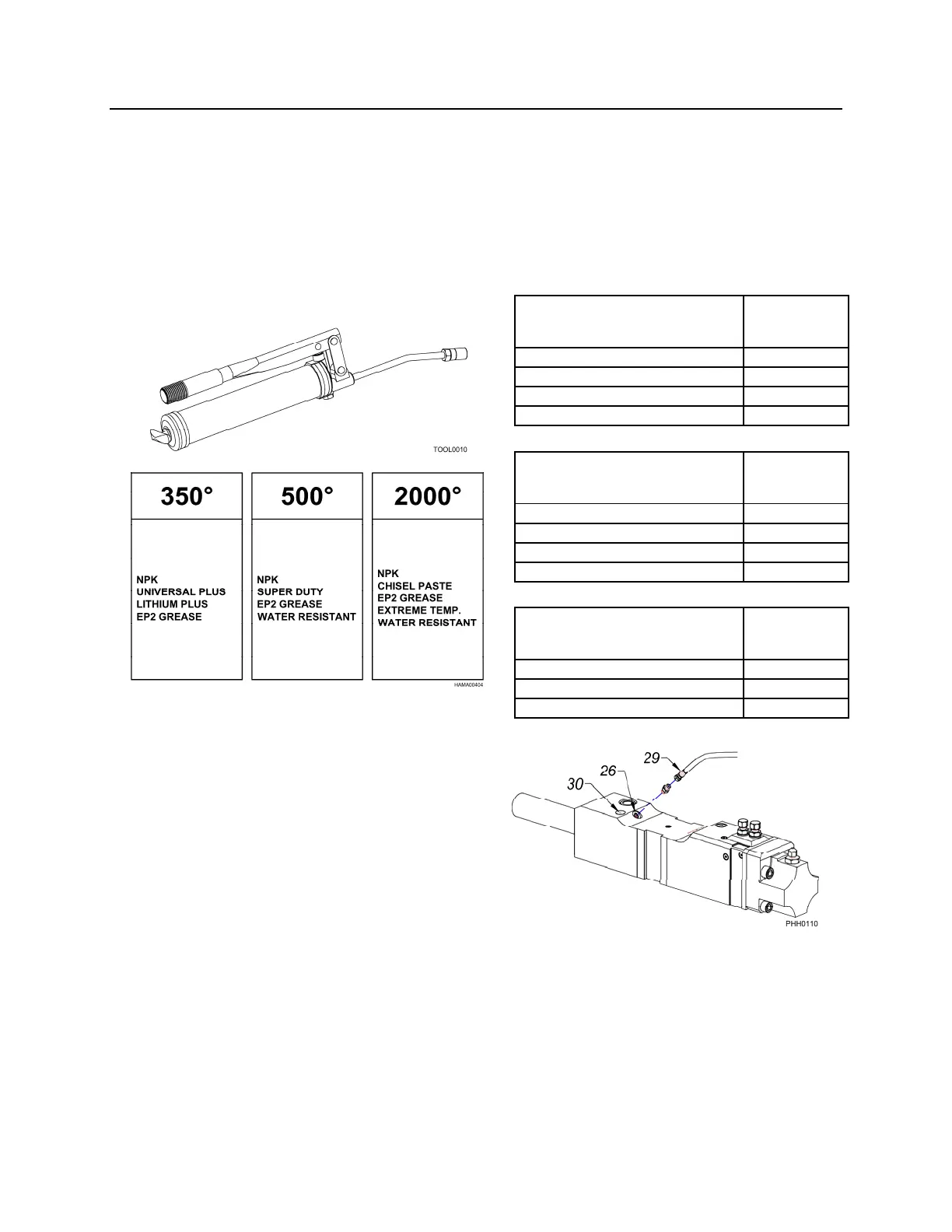

CORRECT GREASE FOR HYDRAULIC HAMMERS

NPK HAMMER GREASE

NPK now offers hammer grease specially formulated to meet severe job requirements.

The grease is available in three different temperature ranges - 350°, 500°, and 2000°.

Universal Plus and Super Duty are lithium soap based products that resists washout

and contain NPK-10 additive for surface protection in friction affected areas.

Chisel Paste is an aluminum complex soap base with 12% graphite and copper

additives for extreme operating conditions.

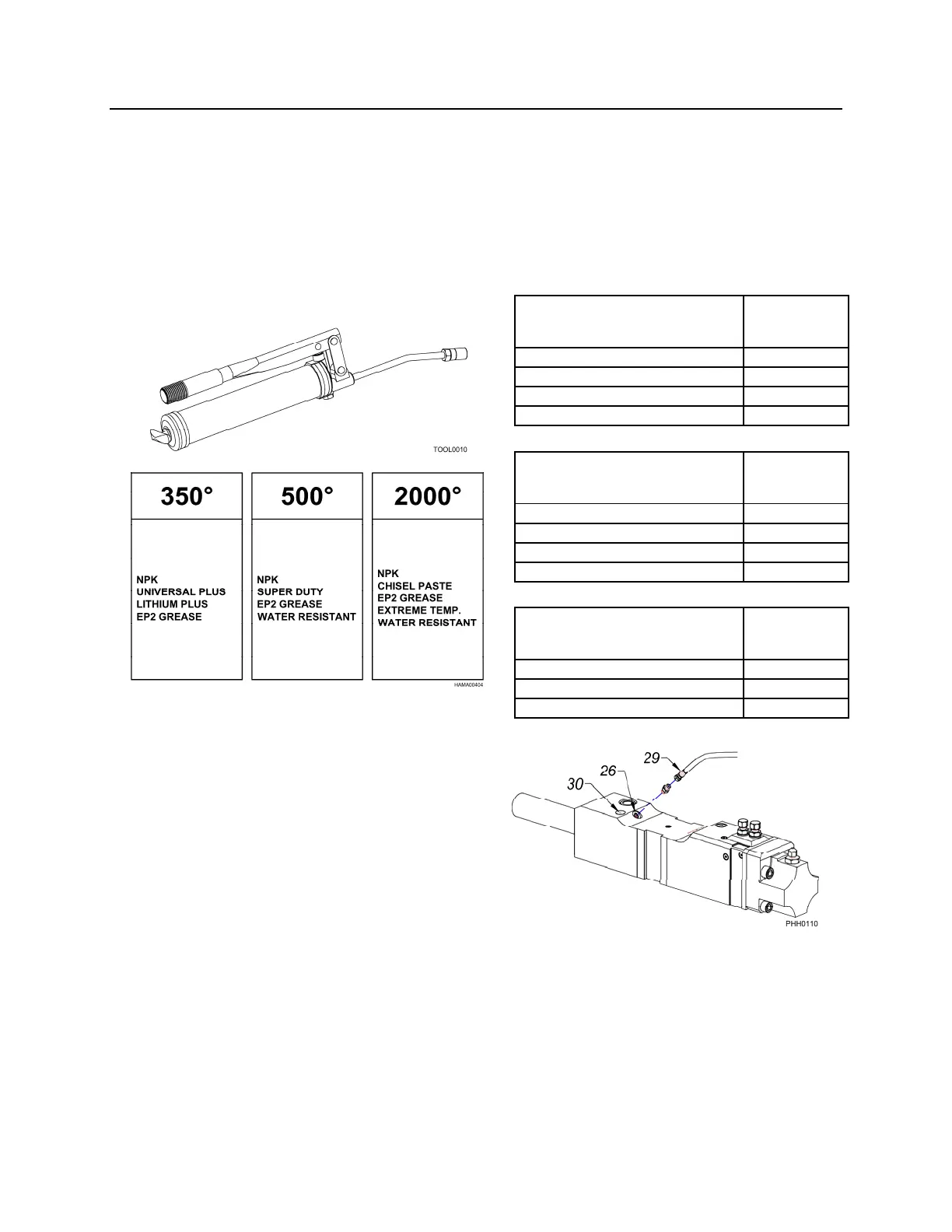

AUTO LUBE SYSTEMS

An automatic greasing system is

recommended to reduce hammer tool and

tool bushing wear. THE NPK AUTO LUBE

SYSTEM is designed to automatically

provide a continuous supply of grease to

the hammer tool and tool bushing –

increasing tool and tool bushing life by

reducing wear. The AUTO LUBE pump is

capable of pumping EP2 grease in cold

weather. The pump output is adjustable

according to the requirements of the

hammer model and to compensate for tool

bushing wear.

26 – AUTO LUBE PORT

29 – GREASE LINE

30 – GREASE FITTING FOR MANUAL

LUBRICATION

NPK GH Series hammer models have a connection port (26) for an automatic greasing

system. Refer to the NPK AUTO LUBE Instruction Manual for details. If the AUTO

LUBE is not used, you can grease unit through fitting (30) as shown.

UNIVERSAL PLUS NPK PART

350 deg NUMBER

14 oz. (.397 kg) CARTRIDGE G000-1010

120 lb. (54 kg) KEG G000-1020

35 lb. (16 kg) PAIL G000-1030

400 lb. (181 kg) DRUM G000-1040

SUPER DUTY NPK PART

500 deg NUMBER

14 oz. (.397 kg) CARTRIDGE G000-1011

120 lb. (54 kg) KEG G000-1021

35 lb. (16 kg) PAIL G000-1031

400 lb. (181 kg) DRUM G000-1041

CHISEL PASTE NPK PART

2000 deg NUMBER

14 oz. CARTRIDGE G000-1050

35 lb. (16 kg) PAIL G000-1060

400 lb. (181 kg) DRUM G000-1070

Loading...

Loading...