- 7 -

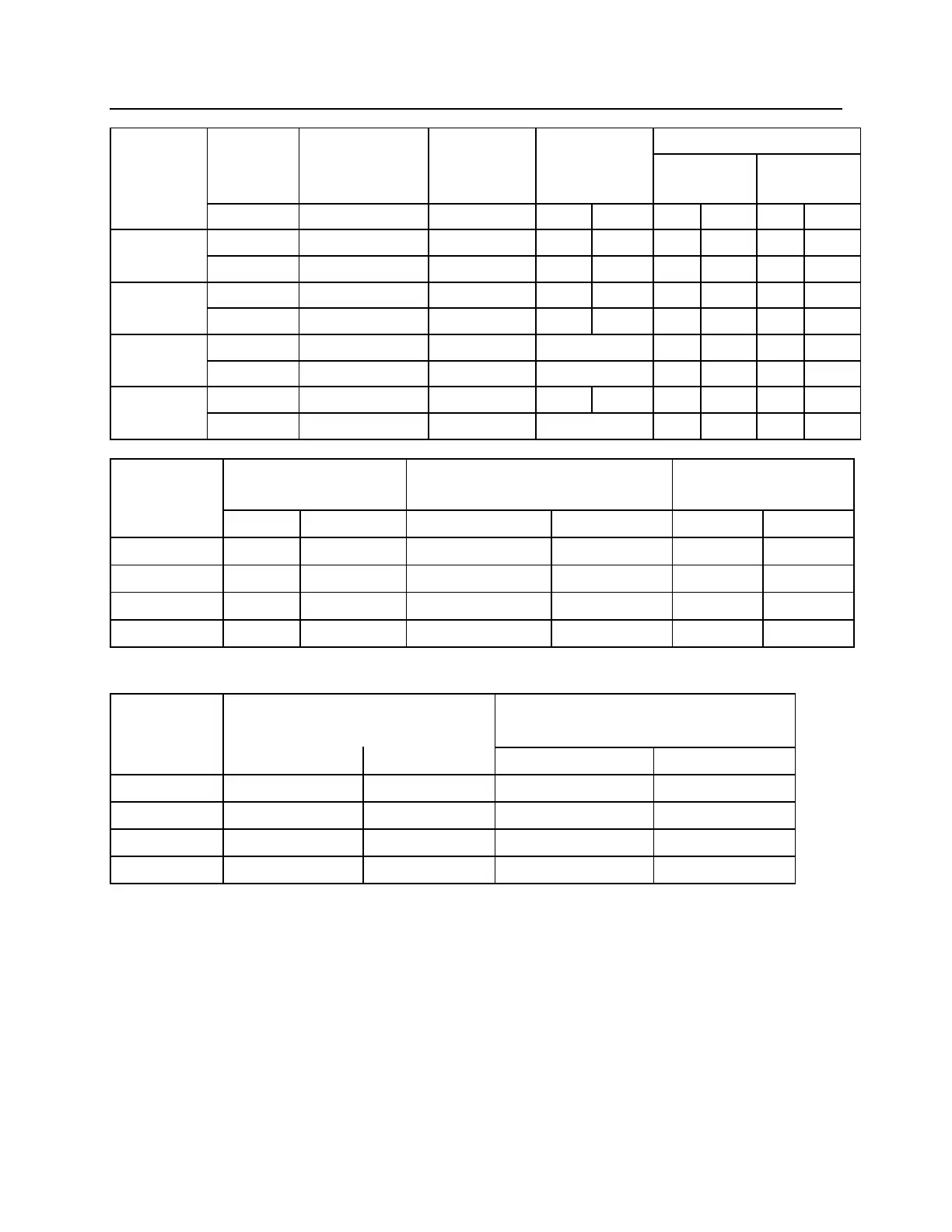

HAMMER SPECIFICATIONS

HAMMER IMPACT FREQUENCY MOUNTING WORKING TOOL

MODEL ENERGY STYLE WEIGHT DIA. WORKING

CLASS LENGTH

ft. lb. bpm lbs. (kg) in. (mm) in. (mm)

PH1

350 550 - 1,100 Excavator 423 (192) 2.24 (57) 14.0 (356)

Skid Steer 674 (306)

PH2

500 500 - 1,200 Excavator 487 (221) 2.60 (66) 15.1 (384)

Skid Steer 735 (333)

PH3

750 500 - 1,150 Excavator 825 (374) 2.99 (76) 16.5 (419)

Skid Steer N/A

PH4

1300 400 - 1,000 Excavator 1,064 (483) 3.39 (86) 18.5 (469)

Skid Steer N/A

HAMMER OIL FLOW HYDRAULIC OPERATING MINIMUM CIRCUIT

MODEL PRESSURE

1

RELIEF

2

gpm

(lpm)

psi

(bar)

psi

(bar)

PH1

7 - 15

(25 - 55)

2,175 - 2,465

(150 - 170)

2,965

(204)

PH2

7 -16

(25 - 60)

2,175 - 2,465

(150 - 170)

2,965

(204)

PH3

12 - 27

(45 - 100)

2,175 - 2,465

(150 - 170)

2,965

(204)

PH4

13 - 32

(50 - 120)

2,175 - 2,465

(150 - 170)

2,965

(204)

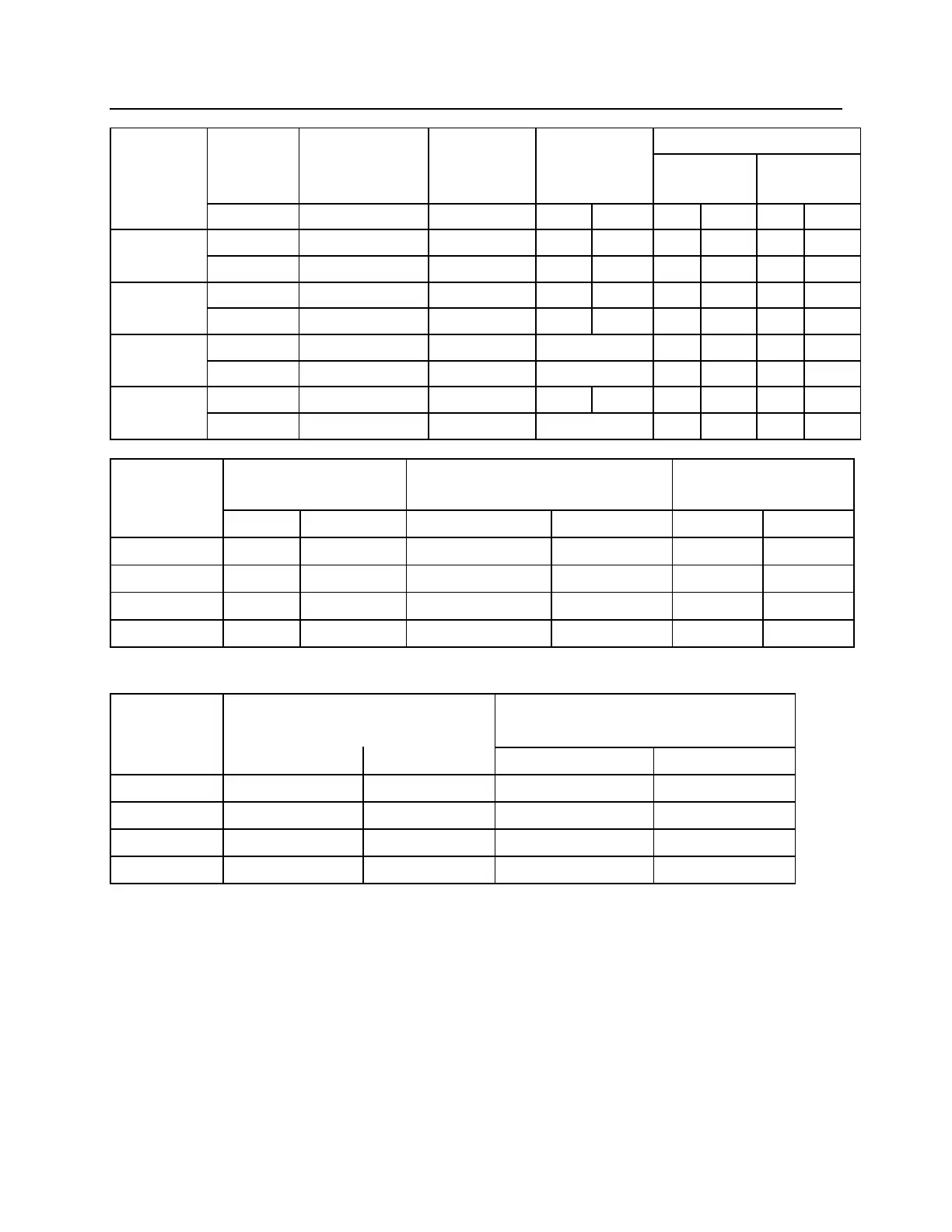

NITROGEN GAS PRECHARGE

HAMMER AT AMBIENT TEMPERATURE

(cold before operating)

AT OPERATING TEMPERATURE (hot,

after 1 to 2 hrs. operation)

MODEL

*psi (bar) *psi (bar)

PH1

175 (12) 220 (15)

PH2

175 (12) 220 (15)

PH3

175 (12) 220 (15)

PH4

175 (12) 220 (15)

*The gas charge tolerances plus 0, minus 25 psi (2 bar).

*Specifications subject to change without notice.

NOTES:

1. Hydraulic operating pressure maximum is inlet pressure at the hammer with the oil at

operating temperature and with the gas charge set at the hot operating pressure. See

CHECKING THE HYDRAULIC PRESSURES section in the Service Manual.

2. Circuit relief pressure is at least 500 psi (35 bar) above hammer operating pressure.

3. Cold gas charge is the initial set with the hammer at ambient temperature.

4. Hot gas charge is checked after 1 to 2 hours of running and with a system oil temperature of

140 to 180F (60

to 80

C). This is the preferred check.

5. Pressures listed are the maximum allowed. Use tolerance of minus 25 psi (2 bar).

Loading...

Loading...