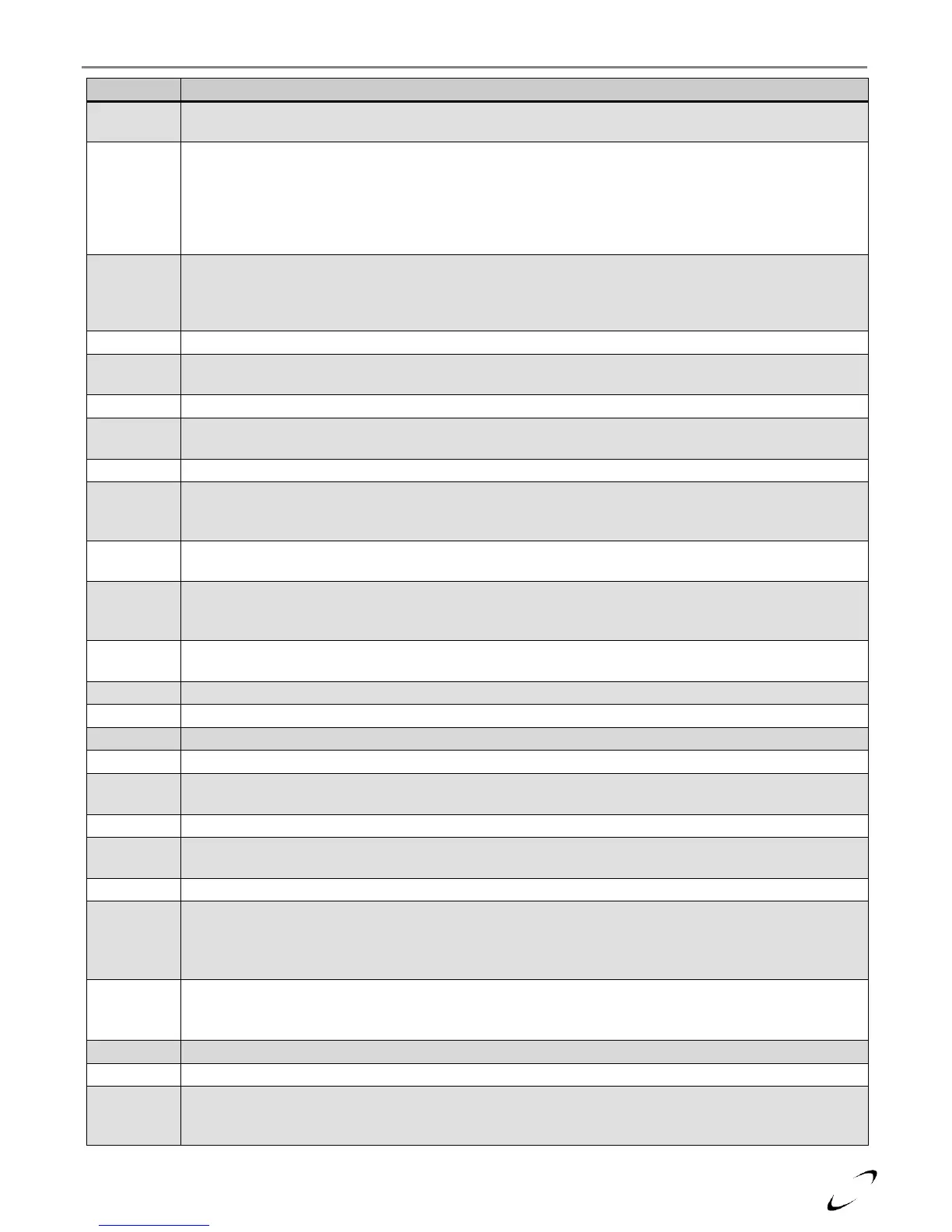

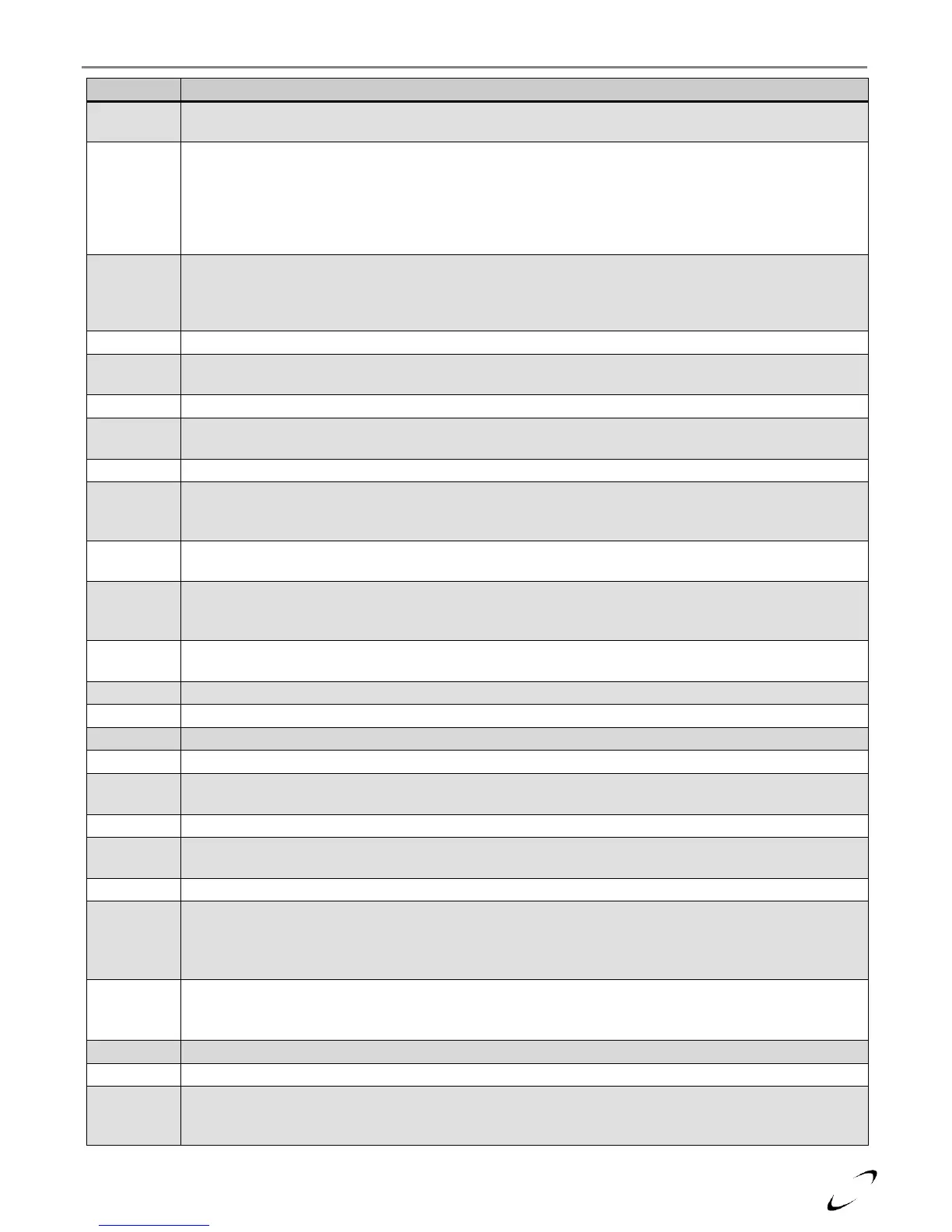

Tx I&O Manual │Display Menu Guide

Gas Valve Circuit Fault (Safety) – control has sensed a fault in the gas valve electrical circuit, check for a

loose connection in the gas valve wiring harness. Also see “Loc 5”.

Limit Circuit Open (Safety) – control has sensed a fault in the safety limit circuit; check the following:

1. External Limit (Purple wire) – if an external limit device (i.e. LWCO) is connected to the purple

wire at the field wiring terminal, check to ensure it has not tripped, and that it is wired correctly.

2. Internal Limit (Heat Exchanger Thermal Fuse) – the heat exchanger is equipped with a normally

closed thermal fuse; the fuse opens when the heat exchanger gets too hot. If the fuse is open,

contact NTI [see Figure 19-1(a), item 48].

Power Supply Electrical Interference – check for poor line, neutral and ground connections in the wiring

leading to the boiler. Check the internal ground connections within the boiler. Eliminate sources of

electrical noise, i.e. welders, large pump inverters, etc. If power is being supplied by a generator, install an

appropriately sized UPS (Uninterruptible Power Supply).

Controller Malfunction – contact NTI, check field wiring, replace controller.

Supply Sensor Fault – controller has sensed an invalid reading at the Supply/Outlet sensor; check cable,

then replace sensor [see Figure 19-1(a), item 15].

Uncorrected Blocking Error – a blocking error (Err) has lasted for 20 consecutive hours.

Incorrect Fan Speed – measured fan speed is not reaching target fan speed within 60 seconds. Check

wiring to fan, replace fan.

Controller Malfunction – contact NTI, check field wiring, replace controller.

Excessive Supply Temperature Reading – controller has sensed an excessive temperature reading at the

Supply/Outlet sensor; verify proper water circulation, check supply sensor cable, then replace sensor [see

Figure 19-1(a), item 15].

Flue Sensor Fault – controller has sensed an invalid reading at the Flue sensor; check cable, then replace

sensor [see Figure 19-1(a), item 20].

Flame present 10 seconds after closing gas valve – verify flame is going out immediately following the

end of a burner demand; check flame sensor (replace); check condensate drain for blockages; increase post

purge setting (Installer Menu setting 2-30).

Flame present before ignition – check flame sensor (replace); check condensate drain for blockages;

increase post purge setting (Installer Menu setting 2-30).

Controller Malfunction – contact NTI, check field wiring, replace controller.

Flame lost three times during one demand – see Loc 1.

Controller Malfunction – contact NTI, check field wiring, replace controller.

Controller Malfunction – contact NTI, check field wiring, replace controller.

Incorrect Field Wiring – check electrical connections to field terminal strip; ensure the Thermostat is

connected to terminals 7 and 8.

Controller Malfunction – contact NTI, check field wiring, replace controller.

Flame detected out of sequence – check/replace flame sensor; check flame sensor wiring; check

condensate drain for blockages; replace controller.

Controller Malfunction – contact NTI, check field wiring, replace controller.

Flue Sensor Error – flue temperature reading exceeds 220⁰F or the sensor is shorted, check flue sensor

connection and wiring. Temporarily disconnect the electrical connector from the flue sensor, if problem

goes away, replace flue sensor [see Figure 19-1(a), item 20]; if problem persists, replace the controller [see

Figure 19-1(d), item 61].

Return Sensor Error – inlet temperature exceeded 203⁰F; error clears when inlet temperature drops below

190⁰F: (1) ensure there is water flow through the boiler, (2) check for correct return sensor reading (menu

reading 1-09), (3) check wiring to return sensor; replace sensor [see Figure 19-1(a), item 24].

Controller Malfunction – contact NTI, check field wiring, replace controller.

Faulty Grounding – check appliance grounding to breaker panel, check internal ground connections.

Incorrect Polarity – controller has sensed reversed polarity of the 120VAC power supply; check field

wiring to L2 NEUTRAL (terminals 12 &13) and L1 120VAC (terminal 14). There should be 120VAC

potential between L1 120VAC and ground, and 0VAC potential between L2 NEUTRAL and ground.

Loading...

Loading...