Cascade Instructions │ Tx I&O Manual

System Sensor – install a system sensor (NTI P/N: 84010) on the outlet (supply) pipe feeding the heating system,

see Figure 13-1. Wire the system sensor to terminals 3 and 4 of the Managing Boiler (left boiler in illustration).

IMPORTANT: the use of the system sensor is mandatory for proper operation of the boiler cascade system.

Outdoor Sensor – when using an outdoor sensor it must be connected to terminals 3 and 5 of the Managing

boiler (left boiler in illustration); outdoor sensors connected to non-Managing boilers will be ignored.

Boiler Pump – each boiler in the cascade must have its own circulator (see Figure 13-1) which is operated by

each respective boiler, via the BOILER PUMP output (terminal 11). The Boiler Pump must be sized according to

Table 10-4.

CH Pump – the Managing Boiler can control the Central Heating Pump via its CH PUMP output (terminal 10).

IMPORTANT: due to the limited switching capacity of the CH PUMP output, it may be necessary to use an

isolation relay to activate the CH Pump, see Table 12-1.

DHW Pump – the Managing Boiler can control the DHW Pump via its DHW PUMP output (terminal 9).

IMPORTANT: due to the limited switching capacity of the DHW PUMP output, it may be necessary to use an

isolation relay to activate the DHW Pump, see Table 12-1.

Central Heat Demand Switch (Room Thermostat) – connect to terminals 7 and 8 (T, T) of the Managing

Boiler. Switch must be an isolated end switch (dry contact). Central Heat settings are programed from the

Managing Boiler only, i.e. Installer menu settings 2-01, 2-02, 2-03, 2-04, 2-05 and 2-06.

Tank Thermostat / Sensor – connect to terminals 3 and 6 of the Managing Boiler. DHW settings are programed

from the Managing Boiler only, i.e. Installer menu settings 2-07, 2-08 and 2-09. Set DHW Mode (Installer menu

setting 2-08) according to device used; Thermostat = 2, Sensor = 1.

Boiler Address – assign a unique boiler address for each boiler in the cascade via Installer menu setting 2-20.

Managing boiler must be set = 1; other boilers must be set from 2 to 16.

Rotation Interval – establishes the time, in days, between advancements of the staging sequence of boilers in the

cascade; set via Installer menu setting 2-22 of the Managing Boiler.

Emergency Setpoint – establishes an emergency (back-up) boiler operating setpoint in the event communication

is lost between boilers, or if the system sensor is not connected. Set via Installer menu setting 2-21 of each boiler

in the cascade.

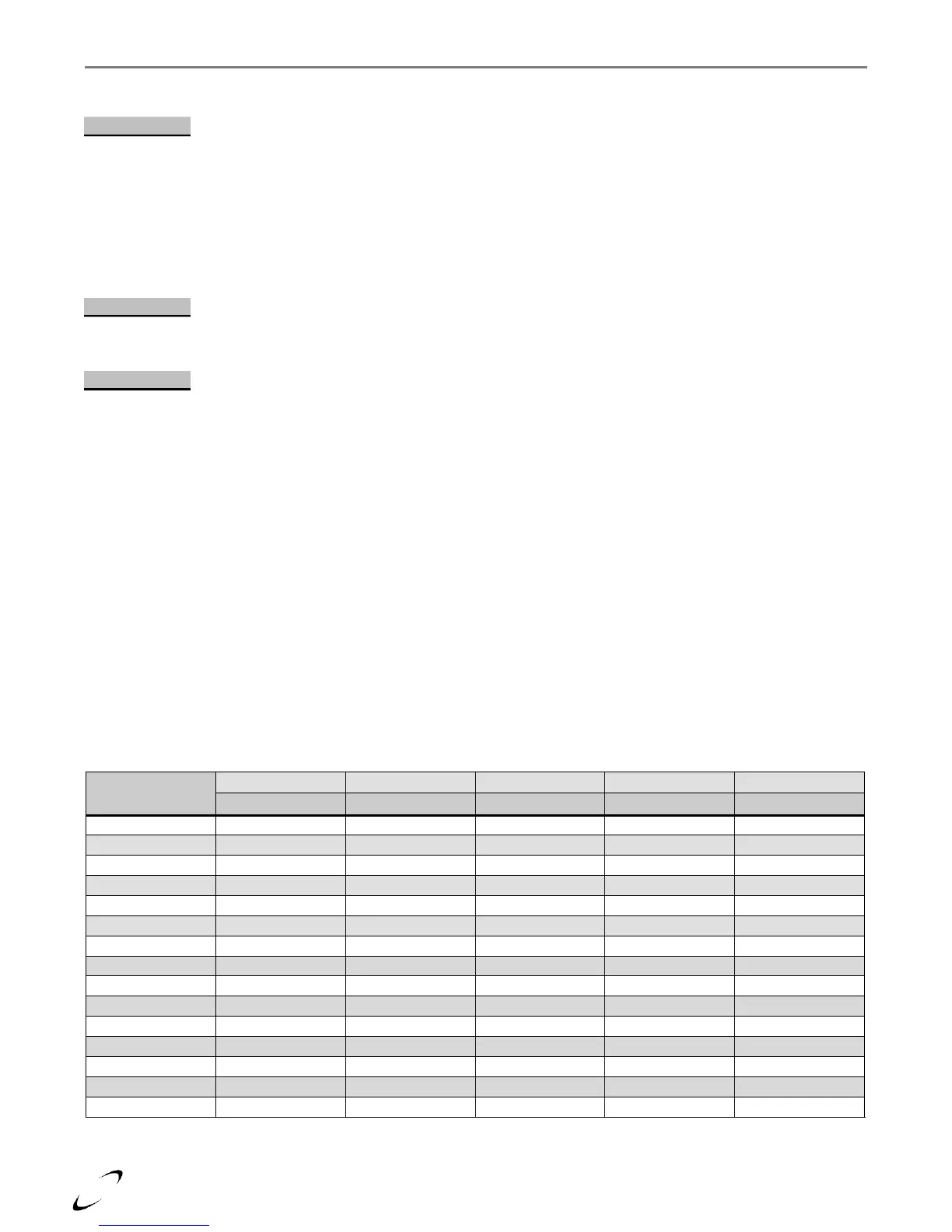

Table 13-1 Minimum Pipe Sizes for Multiple Boiler Applications

Note: Minimum pipe size based on assumed temperature rise of 25ºF at maximum firing rate.

Loading...

Loading...