91

Part 14 - Maintenance

8. Clean the combustion chamber by spraying water or solution

into the combustion assembly and monitor the ow through the

combustion system. Liquid should ow freely through each tube.

If there is an obstruction, increase the ow on the tube to force the

blockage out.

4. Verify and replace the other gaskets if they are damaged or showing

signs of deterioration.

5. Make sure that the burner is not damaged. Replace if necessary.

6. Reassemble the burner assembly.

7. Ensure the combustion assembly sealing ring is not damaged.

Replace if necessary.

8. Reinstall the two removed electrodes with the four removed screws.

9. Reassemble the combustion assembly and tighten the four screws.

10. Reconnect the gas line. Replace the sealing ring.

11. Reconnect the electrode electrical connections.

12. Reinstall the silencer.

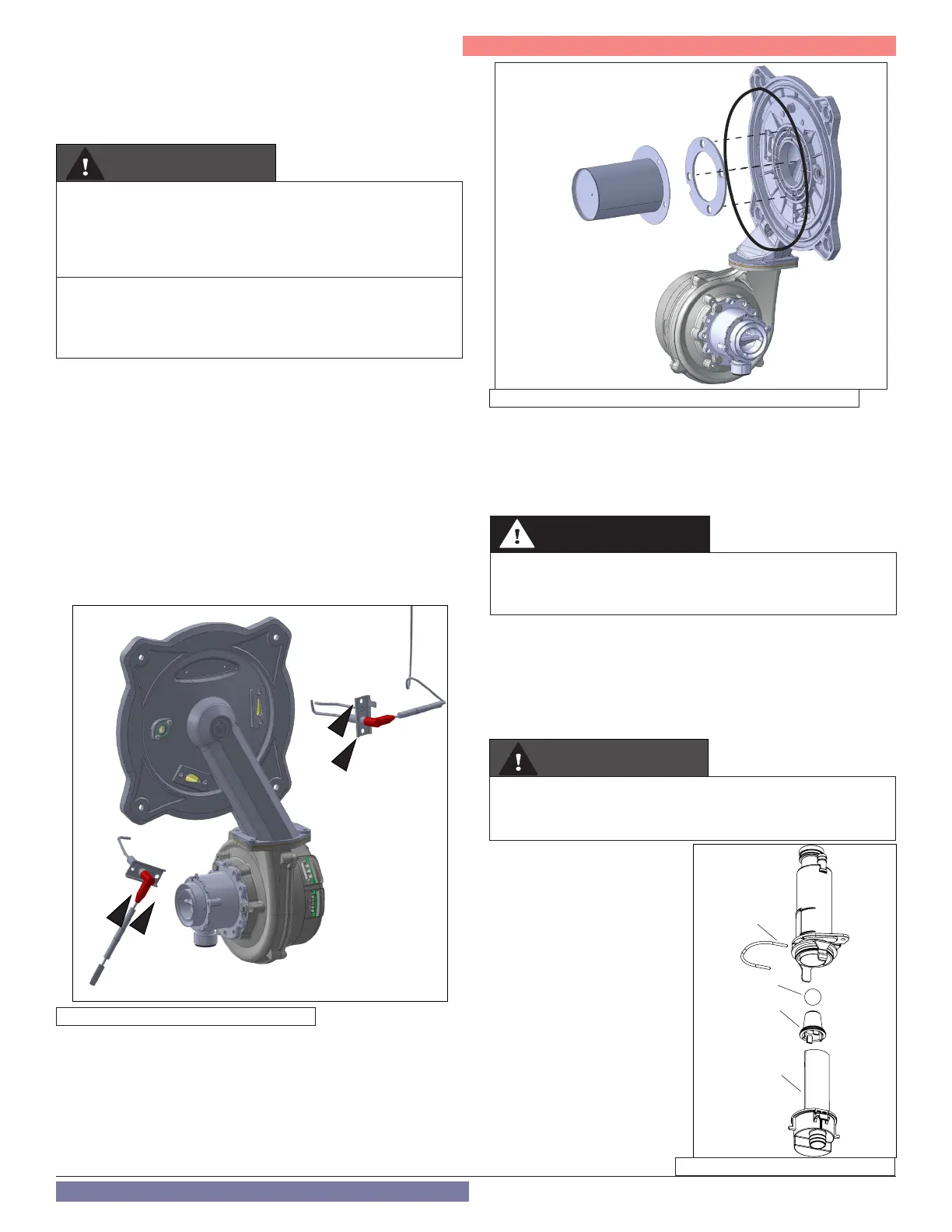

Clean the Condensate Trap

1. Remove the condensate drain hose from the bottom of the boiler.

2. Working from below the

boiler, remove the siphon

cap retaining clip. Then

remove the siphon cap

by depressing the two (2)

lateral hinges (use a tool if

necessary).

3. Remove the cone and the

ball.

4. Clean each part.

5. When the condensate trap is

suciently clean, reassemble

in the reverse order.

NOTE: Ensure all parts shown in

Figure 87 are installed with the

boiler. If any parts are missing DO

NOT operate the boiler. Replace

the entire condensate trap

assembly.

Do not use solvents to clean any of the boiler components.

The components could be damaged, resulting in unreliable

or unsafe boiler operation, substantial property damage,

severe personal injury, or death.

Figure 85 - Remove the Electrodes

Failure to replace a damaged sealing ring will result in exhaust

gas leaks, substantial property damage, severe personal injury, or

death.

DANGER

WARNING

Take care when removing the condensate hose, as condensate

may escape. Failure to do so could result in property damage due

to leaks, personal injury, or death.

9. After all maintenance is complete, reinstall the combustion

assembly. Ensure all gaskets are installed and all components are

tightened properly.

10. Restore power and gas to the boiler. Restart the boiler. Check for

leaks in the combustion system. Observe operation for 5 to 10

minutes.

If boiler is operating properly, condensate is owing normally, and no

gas leaks are detected, combustion coil cleaning is complete.

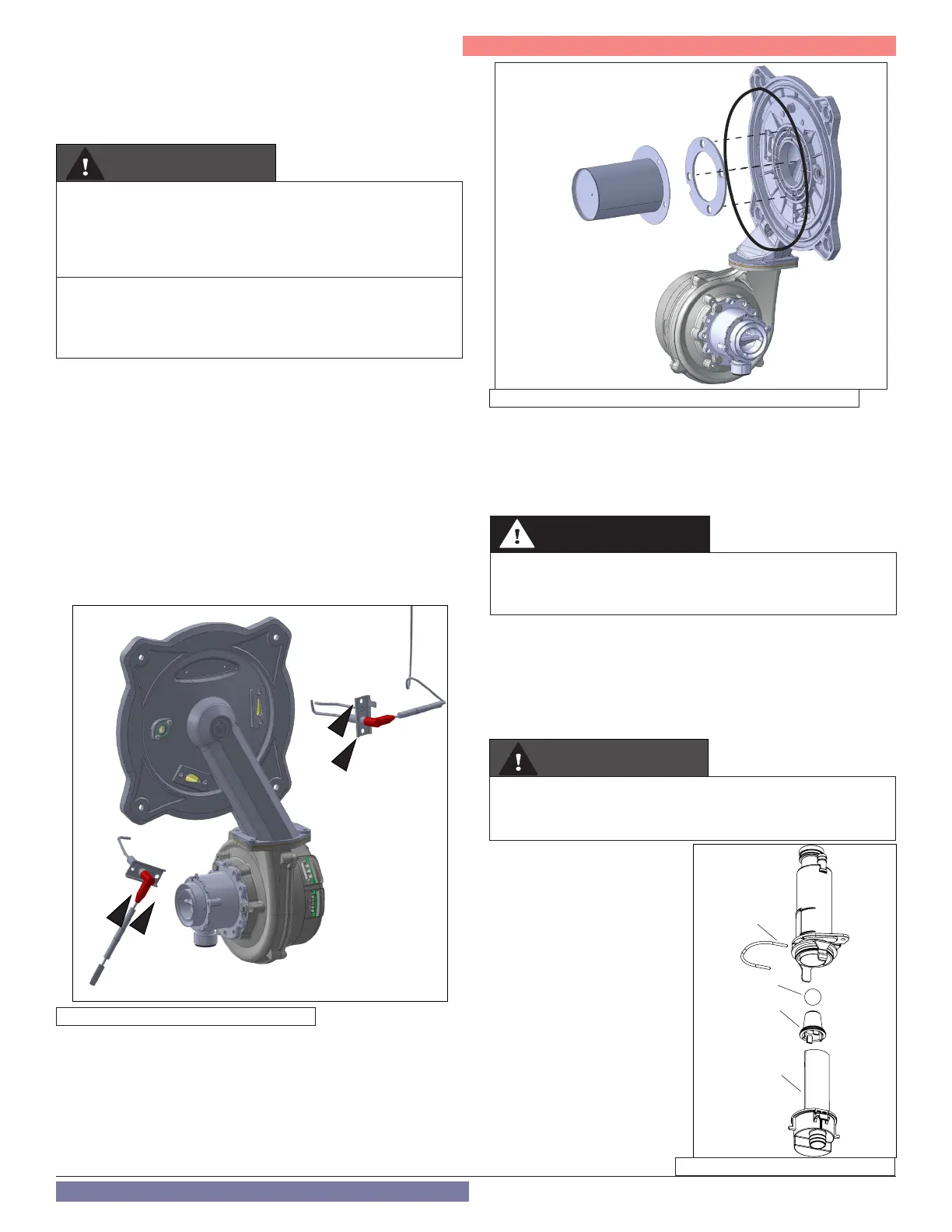

Checking the Burner

While the combustion assembly is removed from the heat exchanger,

inspect the burner. Proceed as follows:

1. Unscrew the four screws securing the two electrodes to the burner

plate.

2. Remove the ceramic ber.

3. Remove the four screws and pull the burner toward you.

NOTE: Whenever replacing the burner, ALWAYS replace the burner

gasket.

Siphon Cap

Retaining Clip

Siphon Cap

Cone

Ball

Figure 86 - Disassembled Burner Assembly

WARNING

Protect the back wall insulation from water before

performing any cleaning. Failure to do so could result

in damage to the insulation, improper boiler operation,

personal injury, or death.

Figure 87 - Clean the Condensate Trap

Loading...

Loading...