22

GB

found to be missing, the machine and its accessories should be

returnedtogetherintheiroriginalpackagingtotheretailer.

Do not throw the packaging away, keep it safe throughout the

guarantee period, then recycle if possible, otherwise dispose

ofitbythepropermeans.Donotletchildrenplaywithempty

plasticbagsduetotheriskofsuffocation.

LOCATING THE MACHINE.

When determining where to locate or permanently fix the

machine,considerationmustbegiventothefollowingpoints.

Isthereasuitablemainsoutletsocketnearby.

This machine must be permanently mounted and firmly secured

onto a bench that is at a suitable height, and that is strong and

stableenoughtocarrytheweightofthemachine.Duringthis

process the machine must be levelled in all planes using a spirit

level.

PREPARING THE MACHINE.

This machine has been supplied with all bare metal surfaces and

accessories treated with an anti rusting protective coating which

mustberemovedbeforeuse.Theidealmethodofremovingthis

protectivecoatingistouseawaterbaseddegreasingagent.

Whenalltheprotectivecoatinghasbeenremovedtheexposed

metal surfaces should be given a light coating of a general

purposelightmachineoil.

FILLING THE GEARBOx.

To fill the gearbox, remove the four socket cap screws that

secure the gearbox cover plate (Pic.2) (2.1). Note that the

matingsurfacesarecoatedwithgreasewhichactsasaseal.

Fill the gearbox with enough mineral based multigrade oil to be

visiblehalfwayupthesightglass(Pic.2)(2.2)..Replacethe

gearbox cover plate ensuring that the mating surfaces are not

contaminated with swarf or other debris, apply a light coating of

greaseandsecurewiththefoursocketcapscrews.

Important Note: Check the oil level in the oil reservoir by

viewing the oil level in the sight glass and top up when the oil

levelisvisibleatthebottomofthesightglass.

RUNNING IN

Beforeusingthemachineitmust be“Run In”,toensurethat

after transit and filling the gear box with oil, the oil is fully

distributedontothegears.Atthesametimethe“V”drivebeltwill

be conditioned and adjustment may be required to compensate

foranystretchingofthe“V”drivebelt.

Set the gearbox selector levers to give the slowest spindle

speed(Pic.3)(3.1).,ifdifficultyisexperiencedinensuringthat

the gears are fully engaged, turn the chuck by hand until the

gearshavefullymeshed.

Ensure that the lead screw automatic drive selector lever is in

thedis-engagedposition.

Plug the mains supply lead into a suitable mains supply socket

and switch on. Switch on the lathe. If any unusual noise or

vibration is experienced switch off the machine and investigate

thecause.

Allow the machine to run at slow speed for twenty minutes

checking for any abnormal conditions including unusual noise

orvibration.Increasethespeedprogressivelyuntilthemachine

hasrunatallspeedsforaminimumoffiveminutes.

Turn the machine off and remove the mains lead from the mains

supply socket.Allow the machine to stand for approximately

fifteenminutes.Afterthistimecheckthemachineforoilleaks

andareasofexcessivetemperature.

Check the movement of all the slide ways by turning the hand

wheels, ensuring that the slide ways travel over their full range

of movement. If movement is stiff or obstructed re-lubricate

the lubrication points and make any required adjustments to

theslideways.To adjusttheslideways (seeexamplePic.4)

slackentheappropriatelockingnuts(Pic.4)(4.1)andturnthe

adjustment screws until the movement of the slide way is free

andwithoutanyplay.Re-tightenthelocknutensuringthatthe

adjustmentscrewsdonotmove.

CHECKING THE “V” DRIVE BELT.

To check that the “V” drive belt is correctly tensioned, using

moderate pressure, press your finger onto the centre of the

drivebeltbetweenthetwopulleys.Thedrivebeltshouldmove

approximately 13mm (Pic.5) (5.1).. If the “V” drive belt has

stretched during the running in period and moves more than

13mm adjustment will be required. Adjustment of the belt

tension is achieved via the adjusting screw and nuts located at

thetopofthemotormountingplate(Pic.6)(6.1).

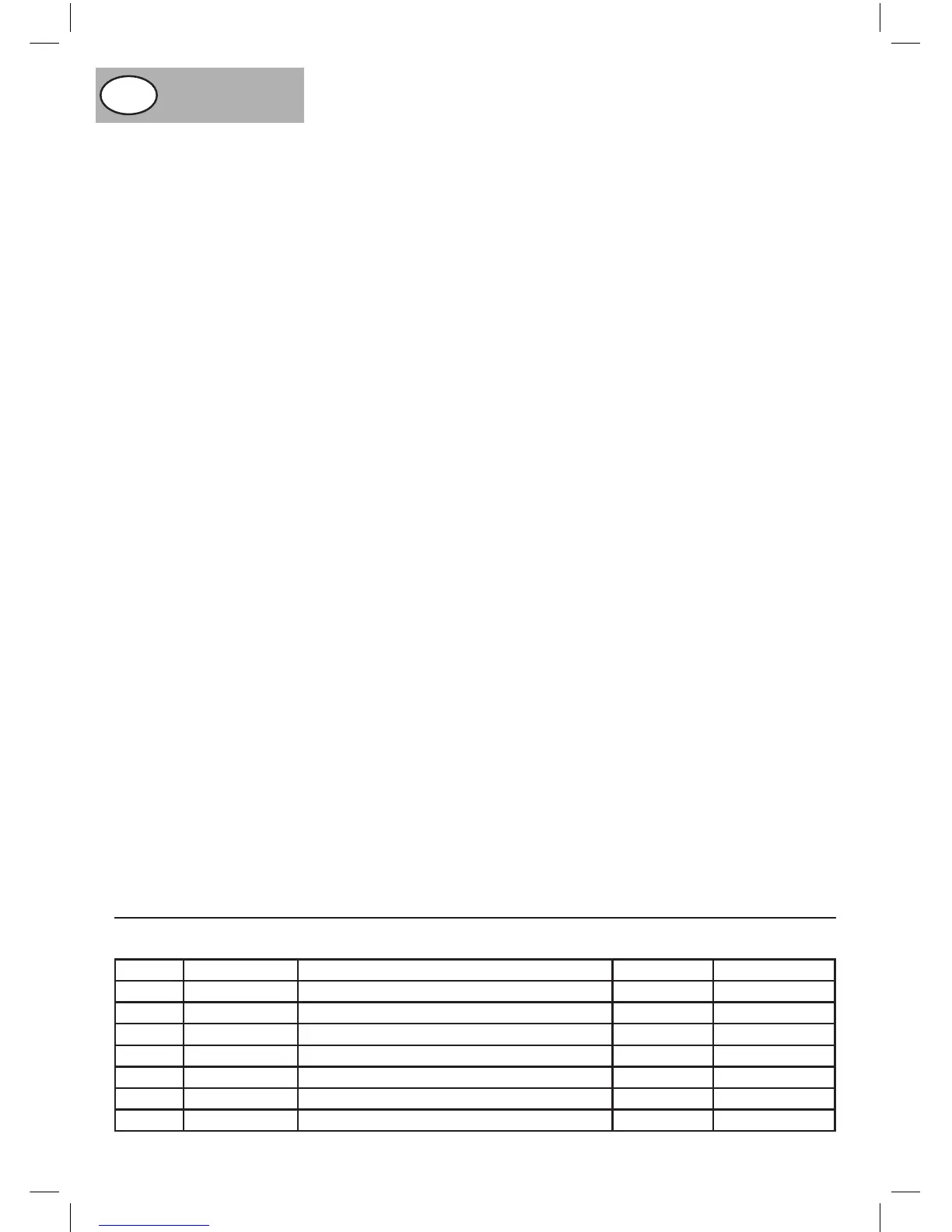

LUBRICATION.

Whentherunninginperiodhasbeensuccessfullycompleted,

lubricationofallothermovingpartsmustbecompleted.using

mineralbasedmultigradeoil.Forlubricationrequirementssee

(Pic.7)andthelubricationchart1.

CHART 1.

Ref: Method

7.1 Gearbox Gears & Bearings Spray Every60days

7.2x4 Saddle Longitudinal slide ways Oil can Every day

7.3x3 Compound slide Slide ways & operating screw thread Oil can Every day

7.4x2 Tail stock Screw thread and barrel Oil can Every day

7.5x3 Lead screw Head & tail stock supports & lead screw thread Oil can Every day

7.6x2 Cross slide Slidewaysandoperatingscrewthread. Oil can Every day

7.7 Thread gears Gears Light spray Every day

Loading...

Loading...