Patent No. 6,766,028 - OFI Testing Equipment, Inc.

OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 6

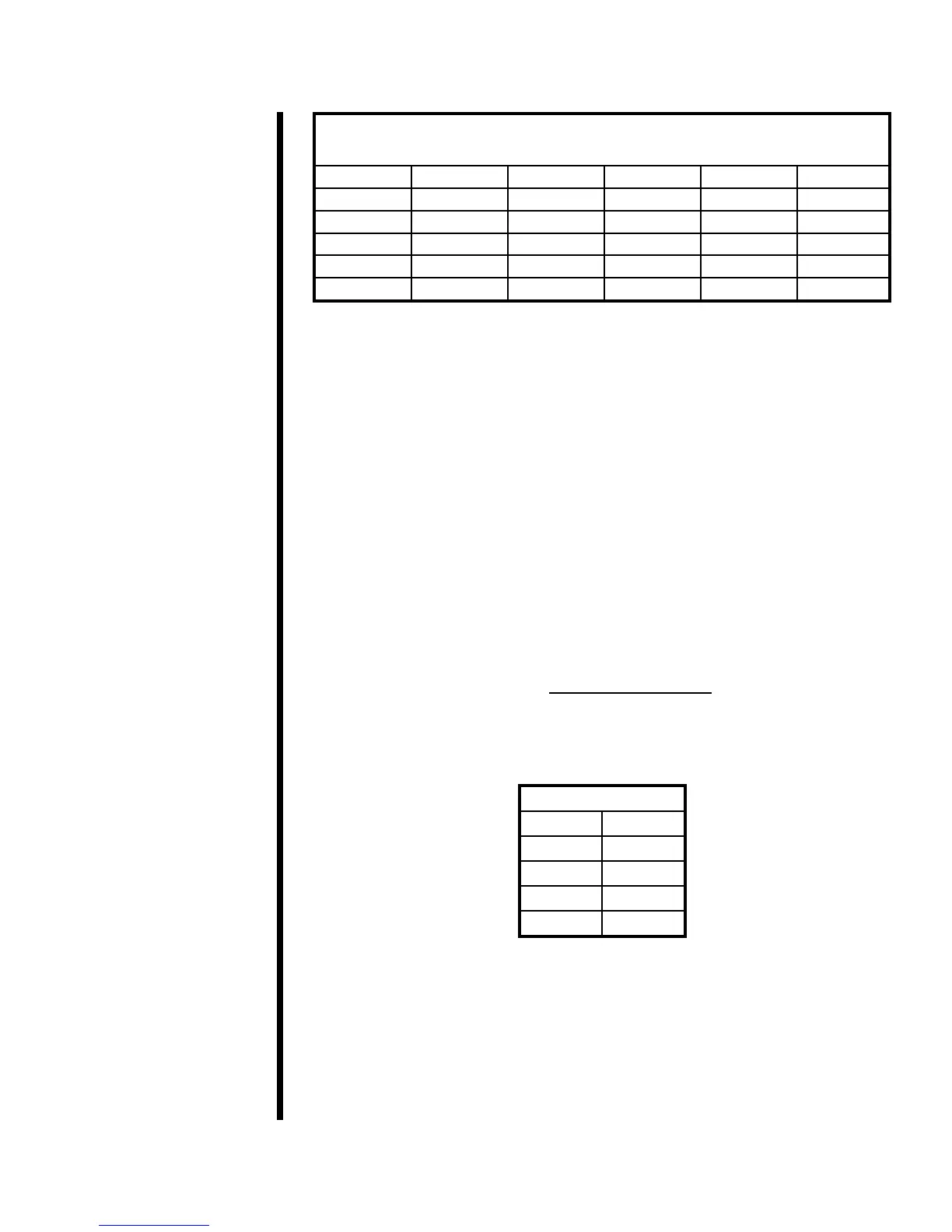

Shear Stress Conversions

To convert from units on left side to units on top, multiply by factor @ intercept.

Dyne/cm

2

Pa lb/100ft

2

lb/ft

2

DR

Dyne/cm

2

1 0.1 0.2084 0.002084 0.1957

Pa 10 1 2.084 0.02084 1.957

lb/100ft

2

4.788 0.4788 1 0.01 0.939

lb/ft

2

478.8 47.88 100 1 93.9

DR 5.107 0.5107 1.065 0.01065 1

What Bob & Spring Should I Use?

There is often confusion or misunderstanding about what a viscometer can

actually measure. For example, a viscometer with an R1B1 F1 combination

can measure water fairly well at 100 RPM and higher, but at 3 RPM, the

readings would be shaky at best. While on the other hand, a linear uid with a

viscosity of 15000, could not get past 6 RPM with the same combination.

To estimate which spring might be best, use the formula below to calculate a

Minimum Spring factor, where one establishes the maximum RPM the uid is

going to be tested at, as well as what the expected “Apparent Viscosity” of the

uid at that RPM. If the Factor comes out as .87, then an F 1.0 spring should

be used. If it comes out as .16, then an F 0.2 spring would be best. To cover

all ranges, it may be necessary to use more than one spring.

Always run the TransCal procedure (steps 10 - 14 on page 51) after

changing the bob or spring.

Minimum Spring Factor (F) =

RPM(max) * AV(max)

BOB(F)*90000

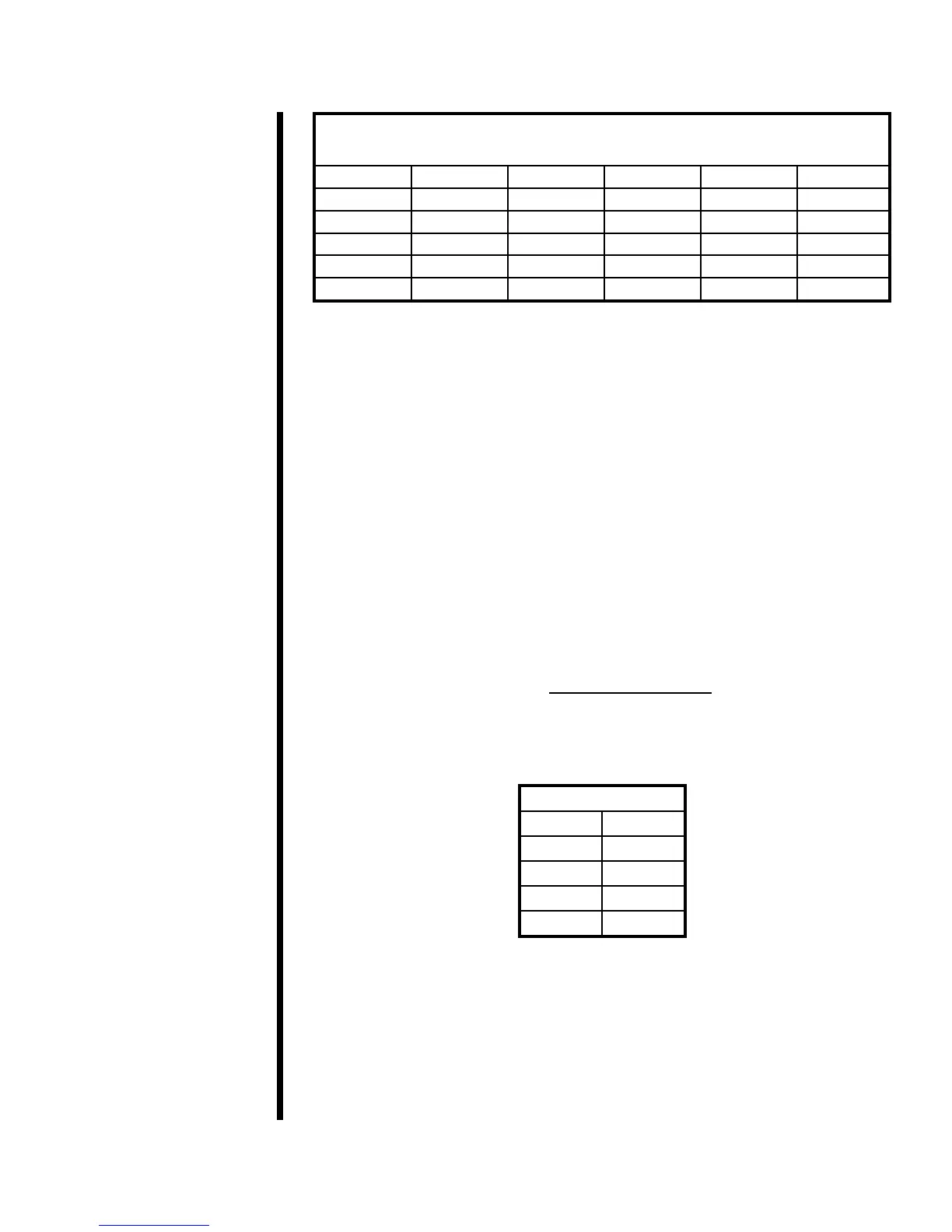

Bob (F)

R1B1 1.0

R1B2 8.9

R1B3 25.4

R1B4 50.7

R1B5 2.4

Loading...

Loading...