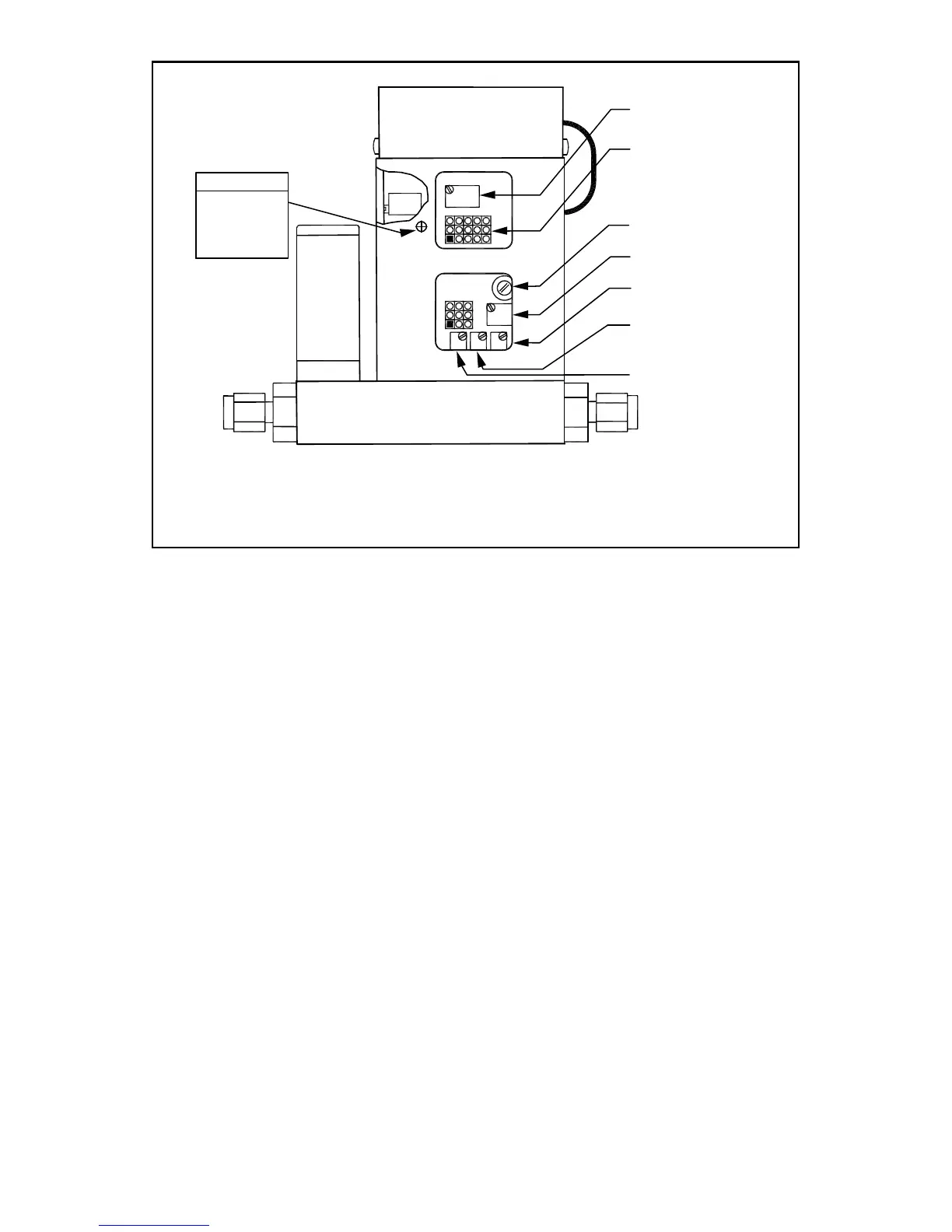

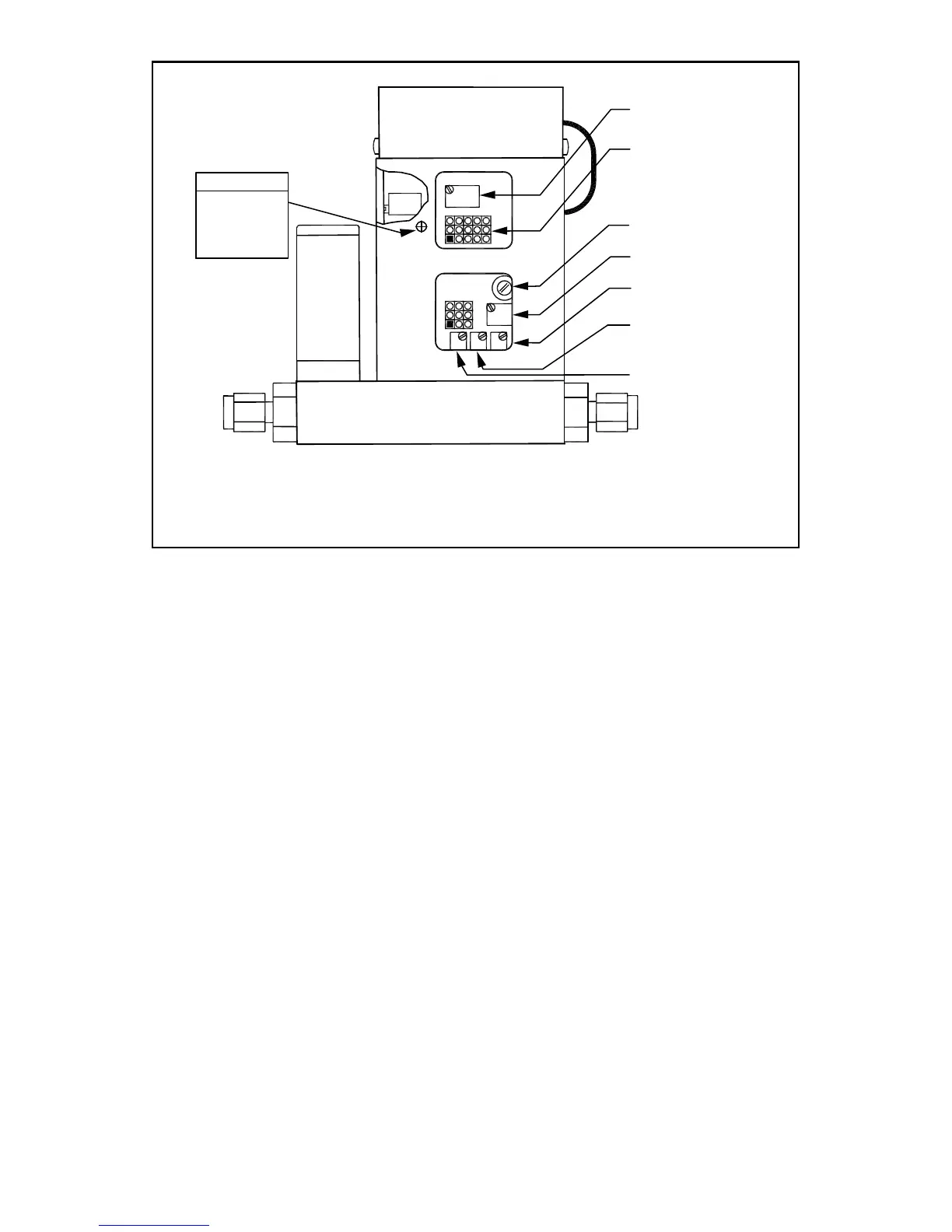

FIGURE 7-3 FMA 5400A/5500A SERIES MAX. FLOW 200, 500 AND 1000 L/MIN

CALIBRATION POTENTIOMETER AND JUMPER LOCATIONS (BACK OF FMA 5400A/5500A)

7.3.1 Connections and Initial Warm Up

At the 15-pin “D” connector of the FMA 5400A/5500A transducer, connect the

multimeter to output pins [1] and [2] for 0 to 5 Vdc (or pins [9] and [14] for 4 to 20

mA) - (see Figure 2-1). When using a remote setpoint for flow control, the appro-

priate reference signal should also be connected to the 15-pin “D” connector at

pins [8] and [10] - (see Figure 2-1). Power up the Mass Flow Controller for at least

30 minutes prior to commencing the calibration procedure.

7.3.2 ZERO Adjustment

Shut off the flow of gas into the Mass Flow Controller. To ensure that no seepage

or leak occurs into the meter, temporarily disconnect the gas source. Using the

multimeter and the insulated screwdriver, adjust the ZERO potentiometer [R34]

through the access window for 0 Vdc (or 4 mA respectively) at zero flow.

7.3.3 SPAN Adjustment

Reconnect the gas source. Adjust the control setpoint to 100% of full scale flow.

Check the flow rate indicated against the flow calibrator. If the deviation is less

than ±10% of full scale reading, correct the SPAN potentiometer [R33] setting by

using the insulated screwdriver through the access window, to eliminate any devi-

ation. If the deviation is larger than ±10% of full scale reading, a defective condi-

tion may be present.

Loading...

Loading...